- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision drives

Results for

Precision drives - Import export

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

FÖHRENBACH GMBH

Germany

The profiled guide slide PFS is available in 5 series with sizes from 100 mm up to 425 mm width and strokes up to 2000 mm. To protect them against dirt accumulations, the slides are covered with bellow covers. Other covers on request. The slides are available in aluminium (nature anodized), or casted iron GGK-25. Optional steel C-45. The ball thread spindle drives are available in the qualities T5 and T7 with spindle pitches from 5 to 50 mm. PFS (basic equipment) ball screw spindle acc. to standard type allocation screwed up bellows cover coated on both sides integrated inductive limit switches (PNP break contact) incl. plug-connector in the endplate

Request for a quote

FÖHRENBACH GMBH

Germany

Type MR - roller bearing mounted slide /Typ MS - dovetail slides Positioning accuracy: 0,001 - 0,1 mm according to the spindle used and the feedback system Drive: Stepping or direct-current motors

Request for a quote

FÖHRENBACH GMBH

Germany

The V shape of the shaft support is the result of purposeful internal development work at Föhrenbach. The most important advantage comes from having the greatest possible distance between the shafts and above all in the lay-out of the four ball-bearing housings whose loadbearing rows of balls are located underneath the shaft. The unitized, modular type like design realized with these devices enables to cover a wide range of application specific solutions. Manufactured in standard widths from 75 to 425 mm and in lenghts of up to 4000 mm, the products are designed to provide solutions that allow to cover almost all handling and mounting tasks that need to be met. An experience of long standing assures for competent solutions.

Request for a quote

IRIS PACK

Poland

New fully automated machine for the production of bags,disposable plastic gloves made of HDPE / LDPE foil. Machine started, tests done. Possibility to check. Station with double unwinding, equipped with clutches for smooth adjustment of HDPE tape tension, double inverters controlling unwinding. The machine uses a central drive that controls all mechanisms responsible for forming production. The feeding of the material is controlled by a stepper motor (servo drive) enabling precise feeding of the HDPE or LDPE tape to the welding position and the final product sorting point. Possibility of changing the welding dies to different sizes of gloves or the production of bags, e.g. for breakfast. Capacity approx. 160 pieces / min Power consumption: 10 Kw Compressed air demand: 8 BAR Weight: 1300 kg

Request for a quote

NORELEM FRANCE

France

Endless toothed belt with trapezoidal profile to DIN 7721 T1 with metric pitch. Ideal for drives with high belt flexibility. Permits smallest pulley diameters. The toothed belts are intended for drives where precision is a requirement, safety is important and the effects of chemicals are a concern. maintenancefree highpower transmission minimal belt extension accurate positioning and angles very good chemical resistance, especially to oils, greases and fuels extremely high abrasion resistance transmits power up to 30 kW reliable speed up to 10,000 rpm

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quote

SPIROL

Germany

The Model PMH easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. The precisely machined rack and casting results in smooth operation, precise positioning, repeatability, and durability. The Model PMH Heavy Duty Manual Pin Inserter installs pins ranging in diameter from 0.8mm-10mm (.031”-.375”) with a maximum insertion force of 6.7 kN (1,500 lbs).

Request for a quote

FÖHRENBACH GMBH

Germany

The series of RT2A distinguishes by compact design with integrated precision roller bearing and worm drive. The rotary tables are sealed, IP 50 and can be driven in all fitted positions. For the mounting, standard drilling plans and special mounting flange and clamps can be used. Different limit switches are available: Standard: reference impulse, PNP-NC, 2 channel.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Sonic torque wrenches have a comfortable ergonomic handle and a clearly visible scale in both NM and FT-LBS and an efficient Sonic pressure locking system. The reversible drive head provides precise torque for clockwise and counterclockwise movements. The QRS Sonic (Quick Release System) guarantees a quick release of the grips, even with slippery hands. Our torque wrenches are supplied in a blow molded impact resistant case. External dimension (D): 40.5 mm Shackle: 45 teeth Newton meters: 40-200 Drive: 1/2''

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Bester 305C welding machine Lincoln AR/CO2 Regulator/ Flowmeter 30L LE Lincoln Electric LGS3 250 G MIG Torch - Air Cooled - 4M Lincoln Electric 305C It is truly a multi-purpose model, ideal for thin sheet and lightweight applications for medium fabrication work. Powerful and compact, excellent for MIG welding The Powertec 305C was designed around the need to satisfy our customers' demand for robust and robust compact MIG welders. Built as a truly multipurpose model, ideal for both thin sheet metal applications and light to medium construction work. Excellent starting performance. Multi-step voltage knobs for precise adjustment. Excellent drive system with transmission roller Electronic feedback system in the wire drive guarantees a constant wire feed speed. Equipped with large diameter wheels, push/pull bar and lifting eyes for total maneuverability. Meets IEC974-1, ROHS and CE standards for safety and reliability.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Powerful and compact, great for MIG welding The Powertec 305C was designed around the need to satisfy our customers' demand for robust and robust compact MIG welders. Built as a true all-rounder, ideal for both thin sheet metal applications and light to medium construction work . Excellent start-up performance. Multi-step voltage knobs for precise adjustment. Excellent drive system with transmission roller Electronic feedback system on the wire drive ensures a constant wire feed speed. Equipped with large diameter wheels, push/pull bar and lifting eyes for total manoeuvrability. Meets IEC974-1, ROHS and CE standards for safety and reliability.

Request for a quote

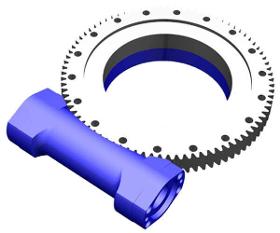

PJM MECHANICAL CO.,LTD

China

Open Housing S Series Slewing Drive Ordering Information When buying a POWER JACK MOTION slewing drive, please note the following: Parameters(New User) You need to consider following parameters Slewing drive radial load Slewing drive axial load Slewing drive installation size Slewing drive precision Miscellaneous Information Make sure to mention your order quantity, expected price, and packing requirements, among others.

Request for a quote

CPC EUROPA GMBH

Germany

Better insulation and high heat dissipation capacity Compact enclosure design for high power density Y-shape/construction for high rigidity — Product for high travel speeds and high precision. — High rigidity with direct drive in closed loop, combined with high accuracy. — High efficiency — The linear motor can be used within clean environments — No pitch error and backlash — Very quiet even at high and low travel speeds — No lubrication required — Very suitable for use in clean rooms — Easy to create systems with multiple motors Magnetic track

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Discover German engineering at its best with our drive components for conveyor belts. Manufactured from high-quality materials, they guarantee efficient and reliable material movement. Wire Belt offers you guaranteed precision-manufactured sprockets, drive shafts and pulleys. Each component is carefully manufactured in Germany to fulfil the highest quality standards. The durability of our drive components reduces follow-up costs and ensures smooth production processes. Our employees are on hand to advise you throughout the life cycle of every project. Based on your needs, you will receive the best recommendation for the respective material requirements in combination with the motor and the conveyor belts. High standards are essential, especially in the food industry. With Wire Belt you will find the right partner.

Request for a quote

CPC EUROPA GMBH

Germany

— Superior electrical insulation and heat dissipation capability — Compact package with high force output — beam design for excellent structural integrity and strength High speed and high precision High-rigidity direct drive coupled with closed-loop control system enables precision control to attain high speed operations with excellent precision performances. In addition, the ironless linear motors are stable and smooth when operated at low speeds. Simple mechanical structure Multiple forcers, each operated individually, can be installed on a single magnetic way to form a simple overall structure that can be readily assembled. For high cleanness requirement applications The linear motor series offer solutions to dirt buildup and lubricant spray mist problems associated with conventional transmission structures containing gear gaps and ball screws. Hence this series is ideal for applications in dust-free environments.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MEDEK & SCHÖRNER GMBH

Austria

High-performance gravure printing machine with turret marking unit for marking hot cable insulation. Ten printing stations Marking of text and numbers Printing speeds up to 1200 m / min Exchangeable ink supply system STANDARD CONFIGURATION Frame with support column and height adjustment crank mechanism. Turret marking unit with precision drive for ten different printing discs. Integrated pneumatic printing disc selector and control electronics with additional input for automatic sequencing via external contact closure. One ink wiping system per printing disc for easy setup and low doctor blade wear. Replaceable, compact ink supply module with ink tank, pump, cooler, filters, and ink flow fine adjustment valve. Complete accessories kit without printing discs. Electronically controlled precision drive for printing disc drive. Ten different marking codes selectable manually or automatically with no loss of marks.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5106 combined the advantage of the GWE 5104 Servo-Insert Coupling with an easy installation. The clamping hubs in split hub design can be mounted lateral at the aligned shaft extensions. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5106 Servo-insert coupling with clamping hubs in split hub design Characteristics Hubs made of aluminum, from size 55 made of steel Standard elastomeric spider with 98° A...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5107 is a compact designed backlash-free Servo-Insert Coupling with an expanding clamp and a clamping hub. Due to the expanding clamp the GWE 5107 can used for examples in hollow shafts. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5107 Servo-insert couplings with clamping hubs and expanding clamps Characteristics Hubs made of aluminum Expanding mandrel and inner cone made of steel Elastomeric spider...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

GERWAH's Servo-Insert Couplings from the production series 'GWE 5103.1' impress with their compact design. The compensating elements are slotted once and mounted by means of a clamping hub. GWE 5103.1 couplings are electrically insulating, installation-friendly and absolutely fail-safe. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5103.1 Miniature servo-insert Coupling with clamping hubs and single...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5103 Servo-Insert Coupling impresses with their compact design and a reduced moment of inertia. Due to the elastomeric spider the GWE 5103 is backlash-free, vibration-damping and electrically insulating. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5103 Servo-insert couplings with clamping hubs, short length and single slit Characteristics Hubs made of aluminum Elastomeric spider sizes 7 and 9 with...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

GWE 5102 miniature is a compact miniature coupling constituting the perfect solution for confined spaces or areas which are difficult to access. The element is connected to the shaft by means of radial set screws instead of a clamping hub. The coupling is available with elastomeric spiders of different degrees of shore hardness. But regardless of the chosen features: GWE 5102 miniature is always electrically insulating and vibration-damping. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying...

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

The cable marker KS 442 C-FM is a high-performance marker specifically designed for high-speed gravure printing on hot plastic insulated wires and plastic jacketed cables in user selectable colors. Due to the extremely high precision of the machine’s drive system, the KS 442 C-FM ensures a non-slip operation and a reduction of the strain on the soft cable insulation to a minimum. Marking of text and numbers Tandem printing head Quick change of legend Print wheel drive up to and above 1200 m/min Exchangeable ink supply system STANDARD CONFIGURATION Tandem marking unit with synchronized drive. Integrated pneumatic printing station selector. Integrated control electronics with additional input for automatic switching via external contact closure. 1 set of dedicated ink wipers and guide rollers matching the specified printing discs. Replaceable ink supply module with ink tank, pump, cooler, filters, and ink flow fine adjustment valve.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The ultrasonic actuators of the SLIMLINE product line are characterized by their extremely slim design and their large variant diversity. These ultrasonic actuator types are available in frequencies of 20, 30, and 35 kHz. A compact console structure, precise guiding systems and variable drive units are a solid basis for repeatable weld results. In combination with Herrmann weld process controls, the system is used for customized integration solutions in automation.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

The cable marker KS 42 C-FM is a high-performance marker specifically designed for high-speed gravure printing on hot plastic insulated wires and plastic jacketed cables in user selectable colors. Due to the extremely high precision of the machine’s drive system, the KS 42 C-FM ensures a non-slip operation and a reduction of the strain on the soft cable insulation to a minimum. Marking of text and numbers Single printing head Quick change of legend Print wheel drive up to and above 1200 m/min Exchangeable ink supply system Rugged, virtually maintenance-free AC drive. Incremental tachometer and reference sensor mounted on the printing disc shaft provide exceptionally accurate synchronization. Automatically synchronized stroboscope of extremely high light efficiency allows proper inspection even at slow marking speeds. Electronically synchronized printing disc drive. Integrated control electronics.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Simplicity without having to abandon the proved Herrmann Ultraschall standards – that are the characteristics of this machine type. Proportional valve technology and digital high-performance generators are basic equipment. A solid machine design with precision guiding rails and proved drive components are the foundation for quality and repeatable welds.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Robustness, accuracy, and simplicity are attributes characterizing this ultrasonic welding machine. The entry-level models already include a position measuring system and proportional valve technology as basic equipment. Moreover, password protection and part counter are standard. Precision guiding rails and reliable drive components ensure repeatable welds.

Request for a quote

STARRAG GMBH

Germany

Fewer rejects thanks to high concentricity and axial runout accuracies (< 2 μm)Wide manufacturing range thanks to precise and powerful table drive (torque motor)Increased productivity through complete machining in just one setup

Request for a quoteResults for

Precision drives - Import exportNumber of results

40 ProductsCountries

Category

- Ink jet printing (3)

- Machine tools, metal machining - parts and accessories (3)

- Slide production (3)

- Engines & Parts (2)

- Harvesting machinery and equipment (2)

- Bags, plastic (1)

- Bearings, roller (1)

- Coil winders (1)

- Conveyor belts (1)

- Food Industry - Machines & Equipment (1)

- Grids, gratings and wire mesh (1)

- Grinding - steels and metals (1)

- Industrial robots (1)

- Internal transport systems (1)

- Labelling machines (1)

- Measurement - Equipment & Instruments (1)

- Metal straightening machines (1)

- Packing and packaging - machinery and equipment (1)

- Precision engineering hand tools, non-power (1)

- Screw cutting - steels and metals (1)