- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- powder metallurgy

Results for

Powder metallurgy - Import export

EUROBALT ENGINEERING OÜ

Estonia

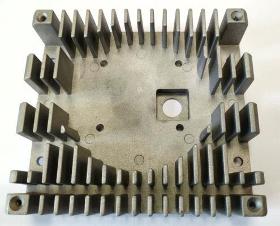

In some cases, metal powders can be easily made of separate metal parts. Powders are used to create floor and building structures, as well as for surfacing. Their application is possible in engineering, nanotechnology, metallurgy, aviation and industrial industry. At our site, you can order production of sintered powder parts. In this article, you will learn about the basic methods of obtaining metal powders. Parts made of sintered metal. Methods for obtaining metal powders are divided into two types: mechanical and physico-chemical. Mechanical methods are more common way to produce metal powders. For this purpose, special devices are used. It is especially advantageous to use this method in the manufacture of powders of beryllium, antimony or chromium.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

We provide the powder metallurgy manufacturing with a wide range of advantages for our clients: Excellent surface finishes Excellent tolerance control Cost-effective processing Inexpensive materials A wider variety of alloys to use A high-quality end products Machining minimization while producing parts Controlled porosity for self-lubrication or filtration Materials that can be heat-treated Our production line provides manufacturing Sintered parts for suspension, Sintered parts for oil pumps, Sintered parts for engine, Sintered parts for start motors, Sintered parts for transmission and other custom parts according to your drawings.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Our production line can produce all base sintered parts for shock absorbers manufacturing. Usually for the manufacture of shock absorber parts we use metal powders Sint C10 and Sint C11, this is the basic material for the production of such parts. Also we can use the material according to your requirements.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We have a long and established history in serving the global Powder Metallurgy industry with substantial historical product developments and leadership representation at Metal Powder Industries Federation (MPIF). Our ability to engineer customized, structural metal powders through water atomization for Powder Metallurgy (PM) applications is world renown, particularly in the automotive and industrial markets. Powder Metallurgy (PM) is the process of pressing and sintering a metal powder into a near net shape part that offers numerous advantages over other metal forming technologies including: High customization such as size, alloy and properties Cost effectiveness and sustainability due to near net shape or net shape production Shape complexity without secondary operation Products We manufacture an extensive range of alloys to numerous customers specifications including chemistry modifications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel powder 304L is a corrosion resistant material that exhibits good property stability below 1000°F. 304L powder is often the most practical stainless steel choice for parts that need the benefit of an austenitic grade. 304 Stainless steel exhibits better overall corrosion resistance than 303 grade. This material is a good choice for parts that will not be subjected to demanding machining operations. A major benefit of this material is the balance of good material performance and economical cost. The 300 Series Powders are austenitic stainless steels typically used for powdered metallurgy (P/M) press and sinter applications to make near net shape parts for a variety of industrial applications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The 300 Series Powders are austenitic stainless steels typically used for powdered metallurgy (P/M) press and sinter applications to make near net shape parts for a variety of industrial applications. Stainless steel powder 303L is a free machining, austenitic grade that offers moderate corrosion resistance. This stainless steel is sintered in either a partial vacuum or a hydrogren atmosphere to improve ductility and corrosion resistance. 303 Stainless steel powder is a sulfurized grade that is an excellent option for parts that require secondary machining operations, such as food service equipment, pump components and nonmagnetic housings.

Request for a quote

NANOCOM LLC

Russia

Application of quasicrystalline powder Al-Cu-Fe: Filler for polymers and elastomers to improve physical, mechanical and antifriction characteristics, wear resistance, hydrophobicity and adhesion. Significant increase in wear resistance in Teflon (PTFE), in Polyphenylene sulfide (PPS); Filler for polymer powders used in 3D printing, Selective Laser Sintering (SLS) additive manufacturing; Development of new composite materials and alloys with improved characteristics in comparison with the original; Reducing friction losses, increasing the service life of units and assemblies, increasing energy efficiency and reducing energy consumption of equipment as an additive in the lubrication systems of mechanisms; Creation of coatings: anti-friction, non-stick, anti-stick, hydrophobic, reducing the level of deposits and slagging of pipes and containers; We propose to test a quasicrystalline powder of the AlCuFe system and its variations doped with boron or silicon.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC turning and Powder metallurgy bronze parts

Request for a quote

MAGMETT METALL INC.

Turkey

ntroducing ALSi, a remarkable aluminum-silicon alloy designed to cater to the needs of the casting industries. Crafted with utmost precision and expertise, ALSi offers unparalleled quality and performance. Our ALSi alloy is meticulously engineered to meet the stringent requirements of casting applications. With its exceptional properties, it ensures superior strength, durability, and impeccable casting results. Not only does ALSi excel in casting industries, but it also finds its utility in powder metallurgy. Its versatile nature allows for seamless integration into various manufacturing processes, expanding its range of applications. Experience the reliability and versatility of ALSi, as it revolutionizes the casting industry with its exceptional performance and unmatched quality. Trust in ALSi to elevate your casting projects to new heights of excellence.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our sophisticated powder metallurgy process allows us to manufacture shaped components including net shapes, bar, plate, rod and tube. These custom-made components are used for critical applications in the mining and drilling, aerospace, electronics and industrial sectors. Pfinodal® (UNS C72900) We offer Pfinodal® (UNS C72900) as a replacement for Toughmet® UNS C72900 material and Beryllium Copper Alloys. AMETEK Specialty Metal Products obtained patents for its powder metallurgically produced product in 1983 and has been serving customers worldwide ever since. Key advantages include: High hardness and strength Non-magnetic properties required in bearing material Low distortion during hardening allows for the complex forming of parts and shapes prior to heat treatment without the need for costly fixtures Non-sparking and non-corrosive Anti-Galling Anti-Seizing Excellent Ductility Excellent Formability Excellent Lubricity Excellent Machinability

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We offer two Spinodal alloy grades produced through the same wrought powder metallurgy as copper based products with nickel and tin additions. Our Pfinodal® (C72900) and AM 388® (C72650) spinodal materials deliver similar mechanical properties to Beryllium Copper alloy (C17200) but without the carcinogenic exposure risks. Advantages include: No carcinogenic elements - only copper/nickel/tin Ductile state and heat treatable Electrically conductive Reduced distortion during heat treatment Reduced stress relaxation Safe Alternative to Beryllium Copper (UNS C17200) Recently, Pfinodal® and AM-388® have been chosen as a replacement for Beryllium Copper due to the carcinogenic effects of Beryllium and fears of bans on Beryllium containing products due to REACH, RoHS, and OSHA mandates. Spinodal materials are gaining acceptance in new projects as well as legacy qualifications as manufacturers, OEMs, and consumers reject products

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK offers a range of wear resistant tool steel powers used in P/M, MIM, and metal additive manufacturing. Tool steels use a combination of C, Cr, Mo, V, and W in an Fe based alloy to generate a carbide microstructure in the metal alloy. Powder Metallurgy (P/M) tool steels offer the highest grade of performance, especially in respect to toughness, due to the extremely fine and uniform distribution of carbides resulting from the atomization process. AMETEK offers multiple grades in the M, D, and T series of tool steels including M3-5, D-2, and T-15 among others. Each tool steel is optimized for its respective purpose to give exceptional properties. Some tool steels, such as our premium T-15 grade, can result in hardness near 70 HRC when appropriately processed and heat treated. Materials that have been routinely produced include M-2, M3-2, M3-5, M4-2, D2, and T15.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK offerswater atomized powder versions of the Tribaloy® alloys T-400 and T-800. These alloys are Cobalt-Molybdenum-Chromium-Silicon (Co-Mo-Cr-Si) based materials that are extremely hard due to the formation of high fractions of intermetallic laves phases. They also exhibit very good oxidation and corrosion performance due to their design chemistry. Tribaloy® alloys are used extensively as hard-phase particles in powder metallurgy of automotive valve seats and guides as well as for other components in the drivetrain requiring enhanced wear performance at elevated temperatures. Tribaloy® alloys are also used extensively for coating and cladding applications in a variety of markets ranging from industrial to aerospace. Tribaloy® T-400 is designed for exceptional wear properties in metal-metal contact scenarios at high temperatures. The alloy has high Co and Mo content and high laves phase fraction leading to very high hardness with reasonable

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK has the metallurgical expertise to produce specialty powders for super-niche and highly engineered applications. Our experience has made us a global leader in the field. Customized and Specialty Alloys Utilizing high pressure water atomization under carefully controlled conditions, we develop innovative powders in an extensive range of standard and custom alloys. Niche Applications Our high alloy powders are used in specialty segments including Sintered Metal Filters, Fiber – polyester and nylon production, Plastic Compounding, Hardfacing and Surface Coating, Powder Metallurgy (P/M), and Metal Injection Molding (MIM). Typical alloys include

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

In recent years, as Powder Metallurgy (P/M) Stainless Steels have become more prevalent in numerous markets, AMETEK has invested in production capability and technology stainless steel powders. Among the results of these efforts are AMETEK’s patented Ultra Stainless Steels™ which are produced by alloying conventional austenitic compositions with a small amount of tin and copper. This combination of metals results in a marked improvement in corrosion resistance when compared to typical austenitic P/M parts while maintaining mechanical properties.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel powder 409L/409CB is a ferritic, weldable grade of stainless steel with key performance features, including high compressibility, enhanced green strength and good sinterability. This stabilized grade provides excellent corrosion resistance and has the capacity to provide high-caliber mechanical properties due to the high temperature sintering response. 409L/409CB’s versatility also results from Cb being less prone to oxidation than Ti. In addition, the oxide is unable to combine with carbon and the Cb forms a stable carbide which prevents coarsening of carbides and grains in the weld’s HAZ. 409L/409CB Stainless steel is a prime candidate for automotive exhaust system applications, among other uses. 409LNI Powder has added nickel for new automotive specifications. Ferritic stainless steel powdered metallurgy (P/M) technology is specified for longer-term performance and reliability. Good atmospheric and saline corrosion

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel powder 316L offers the highest degree of corrosion protection that is available in a standard P/M stainless steel grade. It provides very good strength at extremely high temperatures. AMETEK’s 316 grade stainless steel powder includes many fully customized powder specifications by varying lubricant type, content and particle size. We manufacture high quality 316L powders to fit your applications. 316L stainless steel powders are used in stainless steel flakes and are also used for paint additive manufacturing and chemical filtration. The 300 Series Powders are austenitic stainless steels typically used for powdered metallurgy (P/M) press and sinter applications to make near net shape parts for a variety of industrial applications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products employs a wrought powder metallurgical process to manufacture custom gauge and width strip materials used as the outside sheathing of flux cored wire and metal cored welding wire. Advantages Our high purity process allows production of wire sheathing materials with significant advantages for flux cored welding wire producers, compared to a conventional casting process. These include: Very high ductility Tight and repeatable chemistry control Availability of unique and custom chemistries High purity material for improved tool and die life Corrosion, wear and high temperature resistant Short lead times and small batch sizes Find a consolidated listing of our metal sheathing materials in our Weld Wire Sheathing Brochure. Chemistry Control We tightly control the chemistry of the incoming raw materials to ensure that trace elements are kept to a very low level. Our wrought powder metallurgy process allows chemistry flexibility

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

As a leading metal wire manufacturer, we engineer high tolerance custom shaped wire and flat wire products in a wide range of standard shapes in addition to custom shapes. The range of alloys available is nearly endless with choices from our own high purity wrought powder metallurgy alloys (nickel wire, Pfinodal® wire, Sealvar®, and Nickel Irons). We also process materials from nearly any metal wire manufacturer or rod producer on the planet including stainless wire, steel wire, aluminium wire and more. A comprehensive review of these materials can be found in our Shaped Wire Brochure Standard Shaped Wire Standard shaped wire is available from on-site tooling in round, square, and flat wire products. Edges of flat wire products can be profiled with square, rolled rounded edges, natural round edges or fully blended round edges. Applications for standard shaped wire include

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our pure nickel strip products are custom-engineered to 99.98% purity for critical battery connector applications. We employ an advanced wrought powder metallurgy process to deliver material with significant advantages in comparison to standard wrought nickel battery strip. Key benefits include: 15-20% higher conductivity than traditional cast nickel strip Consistent chemistry control Standard and custom sizes & tempers Short lead-times and small minimum order sizes Superior surface finish Pure Nickel Strip Grades We offer three high purity nickel alloy strip grades that are mainly used for battery connector applications: Nickel 270 – UNS N02270 (899A) - WNR 2.4050 Nickel 270 strip (899A) is our highest purity material with superior conductivity to cast products and offers the most flexibility in design for cost savings, weight reduction, or increased power.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our Electrolytic Copper (C11000) shaped wire is used in magnetic applications such as superconductors in MRI scanners that require high copper content and rectangular cross sections. Electrolytic copper wire products have engineered channels to accept round superconducting wire such as Nb based low temperature wires. We have the expertise to manufacture C11000 copper wire to your exacting specifications and wire shapes. Advantages Our C11000 material for channel wire is produced in long lengths to minimize joints and is tightly tolerance to ensure field integrity. Advantages include: Sophisticated powder metallurgy process achieves high purity, consistency and close composition control Improved die wear, formability and platability Superior dimensional control Stringent quality control to ISO 9001

Request for a quote

TEDORA INTERNATIONAL IMPORT AND EXPORT

Turkey

Microcrystalline Graphite: Graphite is a kind of natural carbon that is soft, grey-black coloured, can be easily pulverized and can be artificially crystallized. Producer continues production with the fully updated flotation plant having the capacity of 4500MT production per month. Values Carbon Rates: 60%, 65%, 70%, 75%, 80%, 85% Size: 100-325 mesh Moisture: 1-2% Packaging: 25-kg kraft sack paper or 1-ton sack Applications Melting and crucible, casting, pencil, carbon brushes in electrical motor and generator, iron and steel industry in metallurgy, dry battery powder, composite parts, aircraft jet engine part, refractory brick and material, casting paint, horizontal retort, stone paint, eletrode, piston ring, thrust bearing, journal bearing, vane, coating, shaft, brake lining, brake pad, fuel cell, gasket, foil, seal, computer circuit board, sport equipment, powder metal, fire retardant, welding, plastic additivies, electro- typing heat changer, carbon raiser, lubricant,chemical,

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

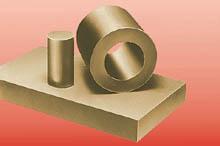

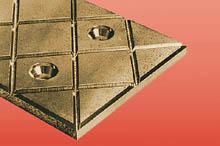

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quoteResults for

Powder metallurgy - Import exportNumber of results

32 ProductsCompany type

Category

- Metal powders (9)

- Sintering - steels and metals (3)

- Steel & Metals (3)

- Copper wires and cables (2)

- Aluminium alloys (1)

- Aluminium and aluminium alloys (1)

- Aluminium wires and cables (1)

- Bronze (1)

- Carbon and graphite - electrical components (1)

- Die casting moulds (1)

- Foundries - copper, bronze and brass (1)

- Plain bearings (1)

- Sheet metal and strips, tinplate (1)

- Surface treatment - machinery and equipment (1)