- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- polymer fillers

Results for

Polymer fillers - Import export

POLYPLAST MÜLLER GMBH

Germany

Fillers characteristically have a high concentration of mineral substances. Depending on the application, properties like increased stiffness, paperlike effects, and improved printability can be achieved in the end product through their use. In addition they can help reduce polymer consumption in order to cut costs.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

We have installed SCHÖPP® Allround structured velour on around 2000 courts since 1994. It can be played on both with and without our Perfect Glide extruder granules, recommended with treadless tennis shoes. Due to its versatility and its very "honest" ball bounce characteristics, it is equally appreciated by all classes of players. From 1994 to 1998, this product was produced with 750 g/sqm. Since then, a pile weight of 1,000 g/sqm has proved its worth. However, the yarn weight can be increased to 1,250 or 1,400 g/sqm on request. This makes the fabric surface even more compact and durable. What is particularly important here is that the higher yarn insert weight leads to a higher pile density of up to 300,000 pimples/sqm and only marginally to a higher pile height, which would have a negative impact on ball bounce behaviour! A higher yarn weight is by no means an equivalent substitute for our highly elastic, filler-free polymer coating!

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

As a world class manufacturer of metallic powders used as plastic additives and fillers, we engineer alloyed stainless steel powders in fine and coarse mesh sizes. Our metal additives are uniquely suited for critical plastic and advanced polymer compounding applications. Products and Sizes We offer several different alloys and sizes of material specifically tailored for polymer compounding. Grades: Our metallurgists and engineers have worked to develop our polymer filler compounding products from 316L, 304L, 430L, and 410L alloys. Sizes: The above grades are typically offered in fine sizes and with surface areas suited to suspension in a variety of polymers. Our Plastic Compounding Fine Powder has a particle size approximately 30 microns.

Request for a quote

MAY ASIT KIMYEVI MAD.TIC.SAN.LTD.STI.

Turkey

Aluminum hydroxide, white solid, is a typical amphoteric hydroxide that is insoluble in water but soluble in acid or alkali. It can be transformed into alumina after heated in the air for dehydration, which is important for alumina production. Aluminum hydroxide is a widely used chemical product, and it is mainly used as plastic and polymer fillers, blanket flame retardant and binder, epoxy resin filler, toothpaste fillers, glass ingredients as well as paper color fillers and coatings. It can be also used to product sulfuric acid Aluminum, alum, aluminum fluoride and sodium aluminate, and to synthesize molecular sieve. The gel and drying gel of aluminum hydroxide can be used in medicine as antacids to neutralize gastric acid and protect ulcer surface for the treatment of gastric and duodenal ulcer disease and hyperacidity

Request for a quote

NANOCOM LLC

Russia

Application of quasicrystalline powder Al-Cu-Fe: Filler for polymers and elastomers to improve physical, mechanical and antifriction characteristics, wear resistance, hydrophobicity and adhesion. Significant increase in wear resistance in Teflon (PTFE), in Polyphenylene sulfide (PPS); Filler for polymer powders used in 3D printing, Selective Laser Sintering (SLS) additive manufacturing; Development of new composite materials and alloys with improved characteristics in comparison with the original; Reducing friction losses, increasing the service life of units and assemblies, increasing energy efficiency and reducing energy consumption of equipment as an additive in the lubrication systems of mechanisms; Creation of coatings: anti-friction, non-stick, anti-stick, hydrophobic, reducing the level of deposits and slagging of pipes and containers; We propose to test a quasicrystalline powder of the AlCuFe system and its variations doped with boron or silicon.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

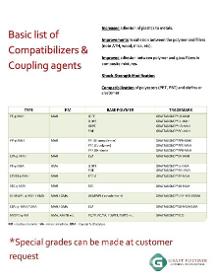

GRAFT POLYMER D.O.O.

Slovenia

Increased adhesion of plastics to metals. Improvements in cohesion between the polymer and fillers (note ATH, wood, mica, etc). Improved adhesion between polymer and glass fibers in composite mixtures. Shock-Strength Modification Compatibilization of polyesters (PET, PBT) and olefins or elastomer. PE-g-MAN (LDPE, LLDPE, HDPE, POE) PP-g-MAN (PPH, PPC, PPR) EVA-g-MAN (EVA) PE-g-GMA (LLDPE, POE) EPDM-g-MAN (EPDM) SBC-g-MAN (SBC) UHMWPE-g-MAN/GMA (UHMWPE powder form) EBA-g-MAN/GMA (EBA) MIX PO-g-PR (PE-PP, PO/PA, PO/PET, PS/PO etc) *PR - Reactive Monomer *MA - Maleic Anhydride *GMA - Glycidyl Methacrylate

Request for a quoteResults for

Polymer fillers - Import exportNumber of results

7 ProductsCompany type