- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding electrodes

Results for

Welding electrodes - Import export

PEMAT S.C.

Poland

The ESAB Handy 200 A electrode welding torch is intended for welding with MMA coated electrodes. It is equipped with a revolving handle with two holes for electrodes. The holes are set at 45 and 90 degrees. After inserting the electrode into the selected hole, clamp the electrode by turning the handle. In this way we ensure comfortable, strong and secure electrode mounting. ADVANTAGES OF THE HANDLE: recommended maximum welding current in a 35% cycle: 200A Diameter of the clamped electrode: 1.6-5 mm Combined welding wire: 16 - 50 mm2 completely isolated handy, allows welding in all positions high quality ensures comfortable, strong and secure electrode mounting the ability to set the electrode at 45 and 90 degrees allows welding in various positions

Request for a quote

PEMAT S.C.

Poland

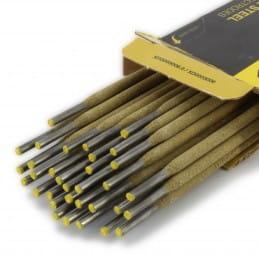

ESAB OK GoldRox 1kg 2.5mm 6013 RUTILE ELECTRODES IGNITE THE GOLDEN ARC OK GOLDROX ELECTRODE BY ESAB - A HIGH-QUALITY COATED ELECTRODE FOR ALL POSITIONS. The 6013 OK GoldRox rutile electrodes offer excellent performance in everyday manual welding tasks, enabling welders of all skill levels to perform them successfully. EASY ARC IGNITION. With OK GoldRox electrodes, ignition and re-ignition are no problem, even when using welding power sources with low idle voltage. EASY SLAG REMOVAL. Using OK GoldRox electrodes allows easy removal of slag, saving time and money in the post-weld cleaning phase. MINIMUM SPRAY. Thanks to the excellent arc stability, OK GoldRox electrodes leave less spatter than standard 6013 electrodes.

Request for a quote

CMPLAST

Poland

Our company's offer includes welding of steel structures made of stainless steel and carbon steel. Welding is carried out using the method MIG / MAG creation of an electric arc between the head and the material. It is covered with shields of mechanical gases such as, for example, neutral (argon) or chemically active (carbon dioxide); TIG welding using a tungsten electrode and a shield of noble (inert) gas, most often argon. We combine elements of standard size as well as largesize items We provide welds with the highest usable parameters, but after the welding process, the combined elements are additionally grinded and we remove any sharp edges or endings

Request for a quote

ELEKTRON SP. Z O.O.

Poland

“Welding” is a manufacturing or carving process that joins materials, usually metals or thermoplastics, using high heat to fuse parts and allow them to cool. The difference between welding and lower-temperature metal joining techniques, such as soldering and brazing, is that welding does not melt the base metal. Thanks to the modern equipment that we have on offer, we can perform, among other things, professional welding of carbon steel, aluminium and other metals using the MAG method and the MIG method. Thanks to experienced specialists working for us, the obtained effect is of very high quality and does not contain harmful contaminants on the ponds. We can also connect structural or stainless steel with the TIG method, using special tungsten electrodes. Welding structures with this technique are very popular because it allows for a very high quality of obtained connections and there are no restrictions on the position in which the connection is made.

Request for a quote

VOSSE SP. Z O.O.

Poland

Metal welding is, the process of welding metals together, performed using heat, superheating or using a welding agent. Each of the above-mentioned solutions is distinguished by different properties, allowing to combine different types of materials and also to apply welding in a specific, well-defined area. We offer our customers comprehensive services in this area with the highest international standards. At our facility, we weld using MAG and TIG methods, in accordance with the international standards set forth in EN ISO 3834-2 for welding metal materials and EN ISO 1090-2. We weld both black and stainless steel. We manufacture structures up to EXC3 class. We have more than 70 WPQR welding qualifications according to EN ISO 15614. Our welders are qualified to weld by methods: MAG 135 - Arc welding with solid wire in active gas shielding. MAG 136 - Arc welding with powdered wire in active gas shielding. TIG 141 - Welding with non-fusible tungsten electrode in an inert gas shield.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MARXAM PROJECT

Poland

The steel welding process is a key technology for the production of metal structures. We weld stainless steel structural elements, as well as entire structures made of structural steel, stainless steel, aluminum and its alloys. The main welding types used by us are: a) arc welding with a consumable electrode in the shield of inert gasses (MIG welding) and active gasses (MAG welding); b) arc welding with a non-consumable electrode in protective gasses (TIG welding); c) 3D laser welding. The specificity of the welding services and its belonging to special processes mean that it is carried out in our plant only by qualified employees who undergo regular training to improve their qualifications. The uncompromising approach allowed us to weld in industries with increased requirements: automotive, aviation and railway. In the metal welding process, we can also use a welding robot, which allows us to achieve high repeatability and welding quality for small and large production series.

Request for a quoteResults for

Welding electrodes - Import exportNumber of results

7 ProductsCountries

Company type