- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- separators

Results for

Separators - Import export

PEMAT S.C.

Poland

ANTI-SPATTER SPRAY VOGELMANN 400ml INTENDED USE Designed to protect a burner's nozzle, tools and surface of welded materials from ingress of metal chips during electric welding works. APPLICATION Before use spray on the area to be protected from approx 30 cm. After welding use a cloth to remove splinters. TECHNICAL DATA Characteristics: flammable, contains PB Content [ml]: 400

Request for a quote

PEMAT S.C.

Poland

Spawmix aerosol spray preparation is an odorless agent used to protect the nozzle of the torch, tools and the surface of the welded metal against the incineration of metal spatter during welding with electrical techniques. Technical data: Catalog number: WYR0010 Characteristic features: combustible, contains PB Application: for nozzles and welded surfaces Content [ml]: 400

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Ultrafiltration extends the life of washwater, floor scrubber and vibratory/tumbling water. PRAB’s line of Ultrafiltration Systems are designed to separate organics, emulsified oils and suspended solids from process water, incoming water, wastewater and metalworking coolant reducing oily water volumes by as much as 98% without the use f chemical additives. For this reason, Ultrafiltration membrane technology is quickly becoming the fluid waste management process of choice over conventional industrial filtration methods. PRAB Water & Wastewater is a leader in fluid management, Ultrafiltration, wastewater reuse, process water reuse, and Reverse Osmosis pre-treatment with partnerships that span globally. Our Ultrafiltration Systems reduce the cost of wash water and detergents by as much as 75% when calculating the costs of replacement chemicals, heating and disposal. Effluent water can be discharged to sewer or reused.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Efficient, High-Volume Fluid Filtration Systems PRAB’s line of vacuum filters eliminate high sludge volume produced in machining centers and grinding applications. Systems range from standard off-the-shelf units to custom-engineered designs, with filtration capability up to 3,000 GPM for efficient, high volume fluid filtration.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Ultraviolet (UV) treatment effectively destroys 99.9% of waterborne microorganisms. PRAB’s line of UV systems for water purification are an environmentally friendly alternative to chlorine disinfection and have no disinfection byproducts (DBP’s). UV purification is used with other forms of filtration, such as a reverse osmosis (RO) and ozone systems and is compact in size. PRAB Water & Wastewater is a leader in fluid waste management, ultrafiltration, wastewater reuse, and reverse osmosis pre-treatment with partnerships that span globally. Our UV systems effectively destroy 99.9% of waterborne microorganisms. Effluent water can be discharged to a sewer or reused. Systems offer a robust design which effectively removes organic impurities from a variety of different water streams for optimum fluid waste management.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Destroy bacteria, inhibit algae growth and reduce scaling in wastewater. PRAB’s line of ozone generators are used for all types of industrial water applications. From recirculated washwater to bacteria control in water-based metal working lubricants and parts rinsing operations. Water treated with ozone does not contain any chlorinated compounds that require further treatment prior to disposal. Ozone is known as the most powerful commercial oxidant in the world, because it is highly reactive and readily oxidizes (breaks down) organic matter. Ozone is used to treat process and wastewater in a sterilization system. It has a faster reaction rate than chemicals and is used as a disinfectant for drinking water, as well as a disinfectant for destroying bacteria, inhibitor to algae growth and scaling reducer in wastewater.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

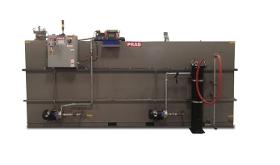

Proven, patented method of fluid reclamation, extend the life of soluble oils, coolants, and washwater. The PRAB Oil/Water Separator uses a proven and patented method for gravity separation of oil from water to less than 15 ppm. This fluid reclamation separator is designed to meet and exceed all performance requirements of U.S. Coast Guard 46CFR162.050 and IMO Resolution A393 (X) of effluent discharge of 15 ppm free and mechanically dispersed oil in water. PRAB Oil/Water Separator filtration technology uses a double packed, fixed, porous media bed for accelerated fluid reclamation allowing the unit to be compact and lightweight. The system consists of the oil/water separator, supply pump with motor and a floating oil skimmer. Optional items include electrical controls, level switches, lid with vent, clean water discharge pump oil holding tank, oil discharge pump, and other customer specified controls and alarms.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Remove Heavy Metals and Organic Compounds from Wastewater to Comply with POTW Discharge Regulations PRAB works with many customers who produce wastewater that is either too acidic or too alkaline to be discharged into the public sewer. In these cases, a reliable pH adjustment system like the fully automated, skid-mounted systems offered by PRAB, could be the solution. The pre-packaged pH Adjustment Systems treat a wide variety of industrial waste streams and are configured to neutralize and automatically adjust the pH of wastewater, greatly reducing labor costs, eliminating accidents and potential illegal discharge violations. PRAB starts with a review of the application and then focus on which pH adjustment system will be best suited for the process. Customizable options are offered, which makes the selection process less challenging. PRAB has streamlined this process with its new water/wastewater analysis instrumentation and complimentary lab with pH testing equipment

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Solutions for Water & Wastewater Treatment For over 30 years, Evaled evaporators and crystallizers have provided wastewater treatment solutions throughout the world. Evaled Heat Pumps, Crystallizers, and Mechanical Vapor Recompression (MVR) units offer clean technology for a wide range of industrial applications, including: Exhausted Oily Emulsions – Degreasing Baths Parts rinsing water – Phosphate coating baths Reverse Osmosis concentrates – Mixed stream wastewater Matching the application and material is critical to reduce corrosion and protect your investment. Evaled technology offers the highest quality products and material selection, with fit for purpose materials AISI 316 Stainless Steel, Super Duplex Stainless Steel and Nickel Alloy

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reverse Osmosis filtration effectively removes dissolved salts, colloidal and suspended matter. Reverse Osmosis filtration removes up to 99.5% of dissolved salts and virtually all colloidal and suspended matter from the most challenging waste and feed water applications. This technology is typically used for industrial, metalworking, and surface treatment applications as a final process after ultrafiltration or chemical treatment of incoming water, process water, or industrial wastewater. PRAB offers Reverse Osmosis (RO) systems for incoming water, process water and industrial wastewater treatment ranging in capacity from 1 gpm (1440 gpd) to 200 gpm (288,000 gpd). This process which removes up to 99.5% of dissolved salts and virtually all colloidal and suspended matter from the most challenging waste and feed water applications.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Minimize maintenance & haul-away costs with a solid bowl industrial centrifuge. Separate solids from liquids where removal of fines is important for recycle and reuse goals. The PRAB industrial centrifuge is ideal for separating all types of ferrous and non-ferrous solids from oils and water-based coolant with flow rates up to 50 gpm. Eliminates consumable media and minimizes maintenance. PRAB’s solid bowl industrial centrifuge is specifically engineered for heavy-duty applications, such as chip processing and industrial wastewater treatment. Our centrifuge provides consistent, reliable operation over long lifecycles. The industrial centrifuge effectively separates solids from liquids in metal processing applications where removal of fines is important to recycle and reuse goals. It provides high performance liquid/solid separation for all types of particles including metallic, ferrous, non-ferrous and non-metallic solids.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Increase Coolant Life, Reduce Coolant Purchases. The PRAB Drum-Type Scraper Separator provides high-quality separation that is applicable to aluminum, non-ferrous, and composite materials. The unit does not consume any filtration materials, savings that go directly to your bottom line.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Cut new coolant purchases up to 75% with the PRAB tramp oil separator system. Extend the life of soluble oils, coolants and washwater. The PRAB tramp oil separator system removes free-floating and mechanically dispersed tramp oils, bacteria, slime, inverted emulsions, and more from individual machine sumps, central systems, and wash tanks. Systems can be installed machine side, or as a centralized system. Payback in as little as 6-9 months. PRAB Tramp oil separators are designed as a simple, trouble-free, economic solution for fluid reclamation- removing free-floating and mechanically dispersed tramp oil from individual machine sumps, central systems and wash tanks.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Proven to reduce new oil purchases by as much as 75%. Extend the life of your oil with the PRAB oil recycling system. PRAB’s Oil Recycling System (ORS) is a centralized, economical solution to the high costs associated with maintaining petroleum- and synthetic-based oils in the metalworking industry. The ORS recycles oils by removing the suspended particles and moisture that shorten the useful life of oil-based fluids, reducing new oil purchases by up to 75%. The system comes available with everything an operation needs to implement a state-of-the-art fluid management program. Each system is designed for easy installation, quick start-up, and simple, efficient operation.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Cost effective fluid clarification for removing ferrous material. Remove ferrous material, including sludge and chips, from both water soluble and neat oils with high intensity ferrite or rare earth magnets. Typical applications include centerless and heavy stock removal grinding machines, honing, and gear cutting machinery. PRAB’s line of magnetic separators employ high-intensity ferrite or rare earth magnets within a fully energized rotating drum to continuously remove ferrous particles from the flow of liquid. These systems are often used as a pre-filter to limit contaminants reaching subsequent filtration equipment. Magnetic separators are well suited to processes where ferrous and non-ferrous contaminants are mixed with water-based coolants or straight cutting oils. They can also be used to enhance chip processing tasks and help you get the most out of your industrial filtration equipment

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Low-profile, cost-effective filtration technology for solids filtration. Low-profile solid/liquid separation of ferrous and non-ferrous metals perfect for grinding applications with flow rates up to 130 gpm. Paper bed filters remove particulate down to 5-microns, prolonging coolant and tool life. Filtered fluid can be reused or recycled lowering operational costs. Standard units ship in 5 days or less. Extend tool life by an average of 27%, improve surface finish and prolong coolant life with PRAB’s line of paper bed filters. Standard paper bed filtration systems are available with flow rates up to 130 gpm with different classes of filter fabric allowing for adjustments of micron clarity. The disposable filter rolls are suitable for applications of low to medium stock removal of ferrous and non-ferrous metals, as well as organic and inorganic contaminants, such as glass, rubber and plastic. Drum-type models occupy one-third the floor space and can process up to 500 gpm of fluids

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

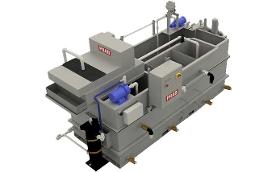

Reduce coolant waste up to 90%. The effective solution to coolant recycling. The PRAB Guardian™ is a centralized system for recycling used coolants, reducing waste fluids up to 90%, and eliminating concerns about wastewater haul-away liabilities. Typical payback in six to nine months. These versatile and centralized coolant recycling systems remove tramp oils and suspended solids from contaminated coolant, control bacteria and can adjust fluid concentration for fluid recovery. Each turnkey system is designed for easy installation, quick start-up, and simple, efficient operation- clearly making it the best coolant recycling solution on the market today. For a calculation of just how quickly you will pay this system back, call us for a free ROI estimate.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Protect your scrap removal and processing system from metal solids. The tramp metal separator is primarily used with a PRAB Chip Processing system for removing bar-ends, broken tooling and other solids from the chip flow. This protects the scrap metal equipment from damage- reducing downtime and costly repairs. PRAB offers a complete line of tramp metal separators and scrap removal systems to remove bar-ends, broken tooling and other solids from chip flow protecting scrap metal equipment from damage. This reduces downtime and saves money on costly repairs.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

VPH type Vibrating Hybrid Screeners in their unique design combine the features of the VPI type screener with the classic screener. The VPH Hybrid Vibrating Screener is a device designed to use a high-performance screening process for materials with properties that make it difficult to screen, such as: High humidity Caking The tendency for the sieves to grow together with the material Low installation height Thanks to the unique design of the device, in which two types of drives operating at different frequencies are used, this screener simultaneously performs the process of crushing and screening of the fed material. This technological solution allows the use of this type of screeners for such works as the process of regeneration of molding sands or screening of fine coal fine fractions.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Vibrating Inertial Screeners with Directly Bitten Screener type VPI are machines designed for high-performance operation with exceptionally low power consumption. The main features that distinguish these screens from traditional machines are their three main advantages: Fixed body – due to the fact that the elements that transmit vibrations to the sieve in these machines are exciters, and not the entire body of the machine, as in the case of traditional screeners, the machine practically does not transfer vibrations to the structure and the ground on which it is placed. Energy efficiency – no need to excite vibrations of the entire device, but only the sieve deck itself, allows the use of small vibrators with low energy consumption. Automatic screen cleaning – as one of the few machines of this type available on the market, VPI Vibrating Screeners are perfect for screening both dry and slightly moist materials (up to 5% humidity).

Request for a quote

RE:QUIET

Poland

to be mounted on the tabletop available in 16 colors Guarding the working place on three sides creating a comfort area can be adapted to the different desk sizes large sizes require corner bracket

Request for a quoteResults for

Separators - Import exportNumber of results

25 ProductsCountries

Company type