- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling and drilling

Results for

Milling and drilling - Import export

PROGRES CNC

Poland

The QUICK TURN SMART 350M CNC turning center provides high performance and unsurpassed production value for medium-sized parts. As an (M) configuration, the machine adds milling, drilling and tapping to its turning capability. This gives the machine Multi-Tasking abilities for even shorter part processing times.

Request for a quote

VOSSE SP. Z O.O.

Poland

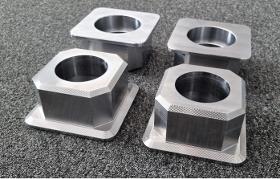

CNC steel machining is a comprehensive service that uses computer-controlled machines to form steel to exact specifications. With advanced CNC technology, it is possible to achieve high quality and repeatability in the production of steel parts, making it a popular method in the metal industry. We offer comprehensive machining services. We produce components in batch runs using CNC technology. We have a developed and modern machine park, which allows us to guarantee the highest quality machining. What we offer in the field of machining: - milling - turning - drilling - planing

Request for a quote

MPRODUCT

Poland

max turning diameter Ø 300 mm max turning length 540 mm turning from bar max Ø 65 mm live tooling (milling, drilling) Y axis

Request for a quote

CIMAT

Poland

Automated Balancing Machines for Brake Discs and Drums Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIMAT

Poland

Balancers for Rotors of Turbines is one of CIMAT’s horizontal balancing machines. Main features universally applicable custom design for every customer permanent calibration and rotor specific calibration as standard intuitive and easy to operate software latest measuring and control unit ROTORTEST based on microprocessor technology different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

At CIMAT, we offer conventional horizontal balancing machines on a bed for rotors of pumps of different size. The greatest advantage of these machines is their versatile application. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant.

Request for a quote

CIMAT

Poland

Our company manufacture and supply special balancing machines for conveyors and rollers used in pulp and paper industry. Main features Bearing force monitoring for automatic shutdown in case of overload, Contactfree measurement of deflection of spinning rollers, Using an appropriate machine design and a suitable safety guarding machines can also be used for highspeed balancing, Permanent calibration and rotor specific calibration, Pedestals with integrated pins and Vblocks, Latest measuring and control unit ROTORTEST, Mass correction types milling, drilling, grinding, punching, welding, adding balancing weights etc., Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Balancing machines on a bed for electric armatures. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant and others.

Request for a quoteResults for

Milling and drilling - Import exportNumber of results

10 ProductsCountries

Company type