- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- measurement and control

Results for

Measurement and control - Import export

ZETEK SP. Z O.O.

Poland

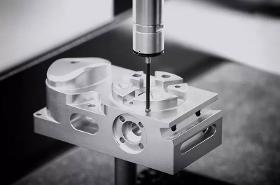

The production of parts for machines and devices, the work of which requires very high precision and matching of each element, must undergo strict quality control. One of its elements is the dimensional compliance test, so important, for example, in the case of elements of bearings, gears or motors. Therefore, control and measurement instruments are an important part of the equipment of every company that carries out such serial production . These include, among others, coordinate machines with which CMM coordinate measurements are made . The precision of these machines' operation creates much greater possibilities than those offered by traditional control instruments - calipers, length gauges, micrometers, etc. The offer of the ZETEK company includes modern control and measuring instruments such as a coordinate measuring machine or a portable measuring arm. Thanks to its mobility, it allows you to take measurements anywhere, outside the laboratory or production hall

Request for a quote

ZETEK SP. Z O.O.

Poland

Serial production of details for the construction of cars, machines or household appliances is associated with the need to maintain a high level of dimensional precision. Especially in the case of machines and components in motion, their parts must be perfectly matched so that they interact without causing friction and accelerating the rate of wear. That is why systematic CMM measurements performed with the use of special coordinate measuring machines are so important. These machines are equipped with three measuring systems enabling simultaneous measurements in the XYZ coordinate axes. An additional element is a probe that allows you to locate the surface of the measured element. CMM coordinate measurementsthey take place automatically and are made with the use of CNC technology, also commonly used in precise CNC machining . Such production tests are characterized by very high accuracy and are not exposed to errors resulting from human physical limitations or his subjective approach

Request for a quote

COMERC SP. Z O.O.

Poland

We design, manufacture, build, train and service The pellet production lines designed and installed by our company offer capacities ranging from 2 t/h to 20 t/h. The capacity achieved naturally depends on the number and power of the machines and equipment comprising the production line. Pellet production lines – the offer: •design (technical conceptual design, formal arrangements, technical documentation, manuals, cost calculation), •supply (machines, devices, measuring and control apparatus, control cabinets, and all installation materials), •installation (machines, devices, control cabinets, measurement, control and feed wiring, post-installation testing, acceptance measurements), •software (controllers, operator panels, visualisation and control systems), •commissioning (machines, devices, control cabinets, control and power installations), •training process operators, programmers and IT technicians and technical human resources, •service within the warranty period and beyon

Request for a quote

ZETEK SP. Z O.O.

Poland

In the vast majority of plants, especially in the automotive, aviation and machine industries, one of the basic requirements is QA - Quality Assurance . This in turn requires reliable and permanent quality control (QC ). Quality assurance and its control are often related, although they are defined differently. The differences between quality assurance and quality control Quality assurance activities and responsibilities usually cover virtually the entire quality system, while QC is a series of quality control activities. In addition, elements of the quality system may not be specifically covered by QA / QC activities and responsibilities, but may include QA and QC. Referring to the above definition, as well as taking into account the industry in which we operate, we come to an important issue, i.e. measurement control. Measurement control The scope of measurement control includes many ways and methods, which often requires devices individually

Request for a quote

ZETEK SP. Z O.O.

Poland

Although control and measurement devices (tests) should and most often are used in a very safe way, they still require cyclical measurement control and regeneration and possible calibration in order to obtain the required measurement accuracy, reliability and repeatability. Ensuring the stability and certainty of quality control - in this case control measurements - translates directly into the quality of manufactured parts and related possible complaints, repair costs and / or service actions. In order to avoid such situations, it is necessary to take care of the impeccable condition of the measuring instruments. Therefore, both in the event of a fault on the gaugecaused by a mechanical factor, related to an accident or an unfortunate coincidence, as well as in the case of the approaching time of cyclic calibration, which, depending on the conditions and intensity of use of the test, should

Request for a quote

CIMAT

Poland

Balancers for Rotors of Turbines is one of CIMAT’s horizontal balancing machines. Main features universally applicable custom design for every customer permanent calibration and rotor specific calibration as standard intuitive and easy to operate software latest measuring and control unit ROTORTEST based on microprocessor technology different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Automated Balancing Machines for Brake Discs and Drums Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

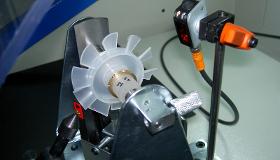

Automated Balancers for Rotors of Supercharger Machinery Directive 2006/42/EC compliant Custom balancers are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Balancing machines on a bed for electric armatures. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant and others.

Request for a quote

CIMAT

Poland

Balancers for Water Meters is one of CIMAT compact balancing machines. The greatest advantage of compact balancing machines is the possibility of easy placement—embedded vibration insulators do not require foundations. As such, our compact machines occupy a small area in comparison to conventional balancing machines on a bed. This is made possible by a guard coupled with the balancing machine body—these guards do not occupy additional square meters of area. In spite of their small dimensions, these compact balancing machines have a robust body with silica sand filling to dampen vibration. As a result, our machines are capable of very accurate measurements and they are less sensitive to outside disturbances. Main features Using an appropriate machine design and a suitable safety guarding machines, Permanent calibration and rotor specific calibration, Pedestals with integrated pins and Vblocks, Latest measuring and control unit ROTORTEST,

Request for a quote

CIMAT

Poland

At CIMAT, we offer a standard range of vertical balancing machines for woodworking tools and saws. As a specialist manufacturer, we also manufacture custom vertical balancing machines for woodworking tools and saws working at high speeds. Our balancers are extremely accurate and provide highquality wood processing. Unbalanced woodworking tools or saws lead to dangerous vibrations, rattling, and poor surface quality. Therefore, we incorporate the latest proven technology and deliver unrivaled accuracy and repeatability, and faster results, than comparable machines on the market. Advantages Machinery Directive 2006/42/EC compliant, Custom balancers are available, Special balancing adapters to fit ISO, HSK, CAT or other tool holders, Newest measuring and control unit ROTORTEST, Mass correction types milling, drilling, grinding, punching, welding, adding balancing weights etc., Safety norms ISO 21940232012 (old ISO 7475 and DIN 45690) compliant, Balancing reports are saved as a PDF

Request for a quote

CIMAT

Poland

High accuracy and efficiency are guaranteed thanks to special software that distributes unbalance to different counterweights for drilling. Onsite drilling station that can travel in different directions and provides fast and easy mass correction. Custom balancers are available upon request. Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant. Permanent calibration and rotor specific calibration as standard Latest measuring and control unit ROTORTEST based on microprocessor technology

Request for a quote

CIMAT

Poland

Machinery Directive 2006/42/EC compliant Custom balancers are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST Balancing reports are saved as a PDF, CSV or XLS, printed on a builtin printer or sent to an ERP system Safety norms ISO 21940232012 (old ISO 7475 and DIN 45690) compliant CIMAT’s software converts amount of unbalance into predefined special balancing clips, which have to be placed on a blade according to the onscreen information Power supply connectors are connected to the motor of the fan automatically

Request for a quote

CIMAT

Poland

Horizontal balancing machines on a bed for wheelsets of different size and construction. Main features automatic connection of spindle to a wheelset with a help of specially designed floating coupling custom design for every customer intuitive and easy to operate software summary reports and possibility to save as PDF, CSV, XLS latest measuring and control unit ROTORTEST based on microprocessor technology different correction methods like eccentric turning, milling, drilling, grinding, adding balancing weights safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

At CIMAT, we offer conventional horizontal balancing machines on a bed. The greatest advantage of these machines is their versatile application. With this machine different rotors could be balanced, such as discshaped, rotors with own journals as well as blowers, turbines, and many others. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, Onsite drilling units are available, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant and others.

Request for a quote

CIMAT

Poland

At CIMAT, we offer conventional horizontal balancing machines on a bed for rotors of pumps of different size. The greatest advantage of these machines is their versatile application. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIMAT

Poland

High accuracy and efficiency are guaranteed thanks to special automatic (or manual) collet adapters with the highest clamping repeatability. Compensation of unbalance caused by eccentricity of adapter clamping. We’ve made component marking obsolete—our machines use the latest rotating speed measuring systems. Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request. Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690)compliant. Permanent calibration and rotor specific calibration as standard. Intuitive and easy to operate software. Latest measuring and control unit ROTORTEST based on microprocessor technology. Different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights.

Request for a quote

CIMAT

Poland

At CIMAT, we offer a wide range of vertical balancing machines for tools and tool holders. As a specialist manufacturer, we also manufacture custom vertical balancing machines for tools and tool holders working at high speeds. Our balancers are extremely accurate and help to provide highquality metal processing. Unbalanced tools or tool holders lead to dangerous vibrations, rattling, and poor surface quality. Therefore, we incorporate the latest proven technology and deliver unrivaled accuracy and repeatability, and faster results, than comparable machines on the market. Advantages Machinery Directive 2006/42/EC compliant. Custom balancers are available. Special balancing adapters to fit ISO, HSK, CAT or other tool holders. Newest measuring and control unit ROTORTEST. Mass correction types milling, drilling, grinding, punching, welding, adding balancing weights etc. Safety norms ISO 21940232012 (old ISO 7475 and DIN 45690) compliant. Balancing reports are saved as a PDF

Request for a quoteResults for

Measurement and control - Import exportNumber of results

20 ProductsCountries

Company type