- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- removal systems

Results for

Removal systems - Import export

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Meter feed directly to scrap metal furnace. Meter feed abrasive die scrap, casting metal, and other materials directly to the melting furnace. PRAB’s furnace feeder scrap removal systems allow you to meter feed abrasive die scrap casting metal and other materials directly to the scrap metal furnace.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Protect your scrap removal and processing system from metal solids. The tramp metal separator is primarily used with a PRAB Chip Processing system for removing bar-ends, broken tooling and other solids from the chip flow. This protects the scrap metal equipment from damage- reducing downtime and costly repairs. PRAB offers a complete line of tramp metal separators and scrap removal systems to remove bar-ends, broken tooling and other solids from chip flow protecting scrap metal equipment from damage. This reduces downtime and saves money on costly repairs.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Compact, skid-mounted scrap metal equipment for turnings volume reduction and solid-liquid separation of small to medium volumes of flowable chips. Fluid reclamation and dry chip output make this scrap removal system ideal for smaller shops

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Industrial metal shredders for reducing light to moderate wads of metal turnings to flowable chips. Reduce volumes by shredding metal turnings into flowable chips for higher value in scrap metal recycling. PRAB’s industrial metal shredders are a safe and cost-effective way to process all types of steel turnings and other metalworking scrap. They use less space for storage prior to scrap metal recycling and provide safer work areas. Available as a system integrated unit for use with chip processing/scrap removal equipment or as a stand-alone unit for volume reduction at the source. The development of automated scrap removal systems begins with reducing the volume of metal turnings. Milling, turning, screw machining, and swiss machining operations all produce waste that varies in size, length, hardness, and configuration depending on the tool, operation, and material characteristics.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce low volume turnings to flowable chips- at the source. Continuous low volume metal scrap reduction at the source. Metal crushers are the economical solution for processing stringy and bulky turnings into flowable chips. This piece can be integrated into existing equipment or free-standing. PRAB’s automated scrap removal systems are designed for volume reduction of metal turnings. The comprehensive focus on chip processing provides metalworking companies with an automated, safe and cost-effective way to process all kinds of metal scrap. The first step in this operation is to create flowable chips from metal turnings with scrap handling equipment. The Horizontal Axis Crusher processes low volumes of stringy and bulky metal turnings. This scrap metal recycling equipment is typically mounted on a stand or heavy-duty cart which fits on the discharge of the conveyor off the machining center

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Cut new coolant purchases up to 75% with the PRAB tramp oil separator system. Extend the life of soluble oils, coolants and washwater. The PRAB tramp oil separator system removes free-floating and mechanically dispersed tramp oils, bacteria, slime, inverted emulsions, and more from individual machine sumps, central systems, and wash tanks. Systems can be installed machine side, or as a centralized system. Payback in as little as 6-9 months. PRAB Tramp oil separators are designed as a simple, trouble-free, economic solution for fluid reclamation- removing free-floating and mechanically dispersed tramp oil from individual machine sumps, central systems and wash tanks.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

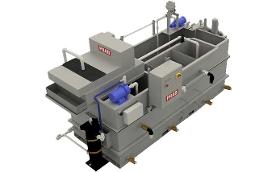

Reduce coolant waste up to 90%. The effective solution to coolant recycling. The PRAB Guardian™ is a centralized system for recycling used coolants, reducing waste fluids up to 90%, and eliminating concerns about wastewater haul-away liabilities. Typical payback in six to nine months. These versatile and centralized coolant recycling systems remove tramp oils and suspended solids from contaminated coolant, control bacteria and can adjust fluid concentration for fluid recovery. Each turnkey system is designed for easy installation, quick start-up, and simple, efficient operation- clearly making it the best coolant recycling solution on the market today. For a calculation of just how quickly you will pay this system back, call us for a free ROI estimate.

Request for a quote

PHSC CHEMICALS SP. Z O.O.

Poland

Principal characteristics and qualities of KTX 30 coating: • a durable isomorphic system allows repetitive removal of graffiti; • single-component preparation – does not require component mixing, does not generate losses caused by the curing of coating that was not used in a specific time – easy application; • creates a thin (approx. 2 - 5 μm), transparent layer of anti-graffiti coating that is easy to wash out; • 1 coating layer ensures full protection; • quick drying – the coating becomes dry in 15 minutes; • exceptionally high efficiency – up to 111 m²/L; • vapour permeable; • graffiti removal with chemical removers; • anti-adhesive, facilitates tape and poster removal; • UV-resistant, does not turn yellow; minimum 10-year durability; • chemical resistance; • anti-static properties; • finishing variants: • matt or gloss; • renews damaged, fogged or oxidised surfaces and restores their natural gloss;

Request for a quote

PHSC CHEMICALS SP. Z O.O.

Poland

Through scientific research supported by numerous tests, we have developed a high-tech anti-graffiti paint marked KTX 07. Principal characteristics and qualities of KTX 07 coating: • a durable synthetic system allows repetitive removal of graffiti (up to 100 cycles); • single-component preparation – does not require component mixing, does not generate losses caused by the curing of coating that was not used in a specific time – easy application; • creates a transparent coating which facilitates graffiti removal; • quick-drying, hardened by the air humidity; • vapour permeable; • removal of graffiti using only normal water or antigraffiti removers; • anti-adhesive, creates an anti-poster effect – poster tapes and adhesives are more difficult to stick to the protected surface; • UV-resistant, does not turn yellow; • 20-year durability; • high chemical resistance; • very good application parameters: from -5 to +30°C; • finishing variants: matt, gloss, RAL colour;

Request for a quoteResults for

Removal systems - Import exportNumber of results

10 ProductsCompany type