- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel%20&%20metals

Results for

Steel%20&%20metals - Import export

MARXAM PROJECT

Poland

At Marxam Project, we specialize in a wide range of forming processes designed to meet the unique needs of our customers. One of our unique services is sheet metal bending – a technique essential for creating durable, custom-made metal components for a variety of applications. Looking to enhance your design with expertly bent sheet metal parts? Contact Marxam Project today to discuss your requirements and discover how our sheet metal bending can benefit your business. Our team is ready and willing to provide you with high-quality, custom solutions. Choose Marxam Project for your sheet metal bending needs and see the difference precision, quality and expertise can make. Let us be your partner in success, delivering exceptional service and excellent results.

Request for a quote

MARXAM PROJECT

Poland

Our spot welders allow the use of alternative methods of joining metal elements. Resistance spot welding is one of the most popular techniques for joining thin-walled metals. The use of condenser welding machines allows for quick and easy mounting of fasteners (pins, screws, pins) on the surface of metals. Induction welding allows you to significantly reduce energy consumption, and thus reduces the cost of manufacturing details. This process significantly reduces the area of thermal action, which contributes to easier cleaning of the joined areas. Induction welding technology allows for its automation, which makes the process repeatable and simpler (and therefore cheaper). Thanks to the use of alternative methods of joining materials, we are able to offer our services in the construction industry; transport of liquids and gasses; automotive industry and machine manufacturing.

Request for a quote

NDS CNC SP. Z O. O.

Poland

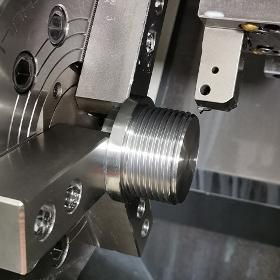

Manufacturing precision steel parts using high feed tools

Request for a quote

NDS CNC SP. Z O. O.

Poland

Manufacturing precision steel parts using high feed tools

Request for a quote

NDS CNC SP. Z O. O.

Poland

STEEL 14301 HEXAGONAL ROD,TURNING + DRILLING USING C-AXIS

Request for a quote

NDS CNC SP. Z O. O.

Poland

CHUCK MILLING PIN TURNING, STEEL S355

Request for a quote

MARXAM PROJECT

Poland

The grinding services are a surface finishing process that includes every detail that requires the removal of machining allowance and obtaining large classes of surface roughness. For technological reasons and the number of requirements as to the further condition of the surface of the elements, we adjust the metal grinding process to individual customer requirements. Metal grinding is a finishing treatment involving the treatment of surfaces of various shapes with abrasive tools. Grinding allows you to remove burrs (deburring) and roughness, as well as machining allowance. This surface finishing method allows to obtain a surface with low roughness and desired shapes and dimensions with quite high accuracy. Surface grinding is one of the most common methods of surface treatment, for a wide variety of metals, including grinding steel, metal grinding bits, grinding welds, aluminum grinding and many others.

Request for a quote

MARXAM PROJECT

Poland

Die-cutting electrical discharge machining (EDM) and wire electrical discharge machining (WEDM) allow for the machining of precise, difficult-to-machine elements with complex shapes, for which the access of a conventional cutting tool is difficult. The wire EDM machining process is also used in our plant to regenerate tools and create injection moulds, dies and gears. Various technological methods are used for the processing of metal products. Wire EDM machining is an erosion treatment that, through electrical discharges, allows metals to be given various shapes, often impossible to achieve by traditional machining methods. Die sinking and wire erosion EDM are the services that Marxam Project encourages you to cooperate in the field of material removal treatment. We are the precision machining company with a wide variety of services, if you are looking for metalworking services, do not hesitate to contact us.

Request for a quote

MARXAM PROJECT

Poland

CNC milling is a modern method of machining that allows for high repeatability, which is particularly important in the case of large-scale production. This process uses numerically controlled (CNC) devices. At Marxam Project, we have many years of experience, during which we have had the opportunity to work on hundreds of milling projects. Trust us with all your machining needs and experience the highest quality of services. Marxam Project is a company dealing with professional and comprehensive metal processing, with particular emphasis on CNC milling. This method is particularly popular with our customers due to the possibility of obtaining various shapes in a quick and repeatable manner. Our experienced technologists have the knowledge and advanced equipment to ensure that we can handle any task. Trust our milling and experience the highest quality of services at attractive prices.

Request for a quote

MARXAM PROJECT

Poland

CNC turning is one of the most modern methods of producing elements using the chip machining method, which, among its many advantages, allows for high repeatability and maximum reduction of production time. CNC turning has developed very strongly in the area of large and medium-series production. In this process, numerically controlled devices are used - hence the name CNC. Over the many years of work on a large number of projects related to turning, Marxam Project has gathered a lot of production experience. This allows our customers to trust us and entrust us with their needs in the field of chip machining. Marxam Project, as a company dealing with professional, and importantly comprehensive, metal processing, also places special emphasis on CNC turning. The need to achieve various shapes in a repeatable and fast way means that customers choose us.

Request for a quote

MARXAM PROJECT

Poland

Entrust your sheet metal stamping to Marxam Project and experience excellence in metalworking. We offer the highest quality of service, precision and efficiency. Our advanced technology and skilled technologists with many years of experience ensure that each piece is carefully stamped to the customer's specifications. Whether you need small, unique parts or large-scale production, Marxam Project has all the necessary tools and knowledge to deliver customized products that will exceed your expectations. When you choose Marxam Project for sheet metal stamping, you are choosing a partner with many years of experience and a commitment to customer satisfaction. What sets us apart is our rigorous quality standards. Contact us today to learn more about our sheet metal stamping services and how we can help you achieve your production goals with precision and efficiency.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MARXAM PROJECT

Poland

If you are looking for precise and efficient metal cutting, look no further than Marxam Project plasma cutting services. Our optimized processes provide the highest quality cuts with a short turnaround time. Contact us for a quote today! Contact Marxam Project today and start working with the professionals in plasma cutting and more. Whether you need unique designs, smooth cuts, or high-volume production, our advanced technology and experienced specialists are ready for your project. Don’t settle for anything less than the best – contact Marxam Project now and let us turn your vision into reality. Your satisfaction is our priority and we would be happy to discuss how our plasma cutting services can meet your needs. Contact us today and experience working with true professionals.

Request for a quote

MARXAM PROJECT

Poland

Modernize your production process with Marxam Project's advanced laser cutting services. With years of experience and qualified specialists, we guarantee that every project will be executed with the utmost precision to offer high-quality products. Whether you need to cut sheets, profiles or pipes, we work closely with our customers to make sure that every detail is executed according to their needs. Discover our laser cutting services and see what their high precision and efficiency can offer you. Contact us today to improve your production processes by working with true professionals.

Request for a quote

MARXAM PROJECT

Poland

Broaching is a machining process that involves removing material using a tool called a broaching machine. A characteristic feature of this method is that it is performed in one pass, which allows for quick production of the element. At Marxam Project, we provide the highest quality metal broaching services. With the help of our specialized tools and qualified staff of technologists, we ensure professional processing and its adaptation to the specific needs of our customers. At Marxam Project, we provide comprehensive metal broaching services, thanks to which it is possible to create various holes and grooves. Using the latest broaching machines and cutting tools, our experienced experts guarantee the highest quality of the created elements. In addition to broaching, we also offer a number of other metal processing activities, thanks to which you can complete your entire project in one place, which will allow you to make sure that all its elements are perfectly matched.

Request for a quote

MARXAM PROJECT

Poland

Honing is one of the processes that are part of the machining process. It is mainly used for machining cylindrical surfaces, such as cylinders. Its main goal is to achieve the appropriate roughness and dimensional and shape accuracy. At Marxam Project, we provide comprehensive honing services that will ensure the highest level of finish. Thanks to our experienced technologists, armed with advanced equipment, we are able to achieve the highest surface accuracy in short lead times. Honing is one of the finishing processes. This means that in order to use it, other activities must be performed to prepare the material. At Marxam Project, we provide comprehensive metalworking services, which means that we can easily apply honing in the processes we conduct. Using modern tools and technologies, we are able to cope with any project of our clients.

Request for a quote

MARXAM PROJECT

Poland

Conventional milling is a machining method that involves the use of manually controlled milling machines to remove unnecessary amounts of processed material, thus giving it a specific shape and properties. At Marxam Project, we provide the highest quality manual milling services that will complement your design and allow you to create exactly what you wanted. Our many years of experience and advanced machinery are a guarantee of quality and customer satisfaction. Trust us in the processes of conventional metal milling and see how we can help you. At Marxam Project, we offer comprehensive conventional milling of the highest quality and fast turnaround times. Our machining experts, equipped with the latest equipment and extensive experience, guarantee precision and adjustment of the manual milling process to your needs.

Request for a quote

MARXAM PROJECT

Poland

Conventional turning is one of the machining methods, which involves the use of manual lathes to remove excess material and give it specific properties. At Marxam Project, we provide the highest quality conventional turning services. With the help of advanced equipment and an experienced team, we personalize our services, the high precision of which guarantees full customer satisfaction. Trust us in turning and provide the best for your project. At Marxam Project, you will experience conventional turning with the highest precision and personalization, which will work great with all other machining processes in your project. Our extensive machine park, which includes the most modern devices and technologies, in the hands of true turning experts is a guarantee of the highest quality and precision of the created elements. Trust Marxam Project in conventional turning and experience cooperation with true professionals in metalworking.

Request for a quote

MARXAM PROJECT

Poland

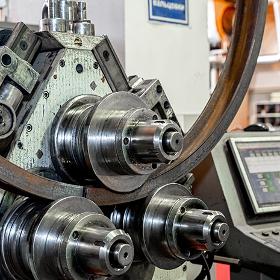

At Marxam Project, we offer highly precise and reliable profile and pipe rolling services. By combining our advanced technology and experienced technologists, we create durable, bespoke tubes and profiles tailored to your requirements. Entrust your rolling to Marxam Project and take your production to the next level. Take your projects to the next level with tube and profile rolling at Marxam Project. Join us and witness your visions materialize with precision and perfection. Contact us today to discuss how we can bring your ideas to life and see what it’s like to work with true professionals.

Request for a quote

MARXAM PROJECT

Poland

Discover the pinnacle of precision and quality with Marxam Project sheet metal rolling services. Advanced rolling technology combined with the expertise of our skilled technologists allows us to transform flat sheets into beautifully curved, multi-dimensional shapes with accuracy and precision. Whether your project requires smooth, uniform curves or intricate forms, at Marxam Project we provide versatile rolling at the highest quality. At Marxam Project we understand the importance of precision and reliability, which is why we strive to exceed your expectations on every project. Our sheet metal rolling services are ideal for a wide range of applications, from durable industrial components to elegant architectural elements. Contact us today to turn your vision into reality and experience what it’s like to work with true professionals.

Request for a quote

MARXAM PROJECT

Poland

The steel welding process is a key technology for the production of metal structures. We weld stainless steel structural elements, as well as entire structures made of structural steel, stainless steel, aluminum and its alloys. The main welding types used by us are: a) arc welding with a consumable electrode in the shield of inert gasses (MIG welding) and active gasses (MAG welding); b) arc welding with a non-consumable electrode in protective gasses (TIG welding); c) 3D laser welding. The specificity of the welding services and its belonging to special processes mean that it is carried out in our plant only by qualified employees who undergo regular training to improve their qualifications. The uncompromising approach allowed us to weld in industries with increased requirements: automotive, aviation and railway. In the metal welding process, we can also use a welding robot, which allows us to achieve high repeatability and welding quality for small and large production series.

Request for a quote

MARXAM PROJECT

Poland

All required protective coatings are made in certified external companies. The basic condition for cooperation is meeting all environmental requirements. Our capabilities include the following metal protective coatings: - aluminum anodizing (soft and hard); - cataphoresis (electrophoretic painting); - electropolishing; - galvanic zinc; - hot-dip galvanized (galvanizing metal); - powder coating. As a production company, we offer: - metal sandblasting of crude steel; - removing paint coatings by sandblasting and soda blasting (without heating and damaging the surface); - glass blasting of stainless steel and aluminum; - unifying the surface after machining and welding; - large-area painting with a hydrodynamic, airless unit.

Request for a quoteResults for

Steel%20&%20metals - Import exportNumber of results

28 ProductsCompany type

Category

- Turning - steels and metals (28)

- Welding work - steels and metal (18)

- Milling - steels and metals (12)

- Cutting - steels and metals (11)

- Bending - steels and metals (3)

- Broaching - steels and metals (2)

- Grinding - steels and metals (1)

- Stamping - steels and metals (1)

- Boring - steels and metals (1)

- Sand blasting - steels and metals (1)