- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- calibration of measurement instruments

Results for

Calibration of measurement instruments - Import export

ZETEK SP. Z O.O.

Poland

The certification of gauges is based on checking that the instrument maintains the prescribed measurement tolerances and MSA processes that confirm the stability of the measurement process of the gauge used in different conditions and by different people. Tests and control and measurement devices undergo the process of checking the current state, and then we carry out the calibration process and recertification. We carry out the certification and calibration process of the gauges in accordance with the procedures resulting from ISO 17025 , which confirms the credibility of our work. At the client's request, we perform work in accordance with the requirements and processes resulting from the individual features or parameters of a given measuring instrument. Calibration of the gauges Calibration is an integral part of the construction and production processes of control and measurement devices and gauges, and is also used during service or repair work.

Request for a quote

ZETEK SP. Z O.O.

Poland

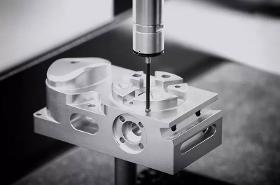

The production of parts for machines and devices, the work of which requires very high precision and matching of each element, must undergo strict quality control. One of its elements is the dimensional compliance test, so important, for example, in the case of elements of bearings, gears or motors. Therefore, control and measurement instruments are an important part of the equipment of every company that carries out such serial production . These include, among others, coordinate machines with which CMM coordinate measurements are made . The precision of these machines' operation creates much greater possibilities than those offered by traditional control instruments - calipers, length gauges, micrometers, etc. The offer of the ZETEK company includes modern control and measuring instruments such as a coordinate measuring machine or a portable measuring arm. Thanks to its mobility, it allows you to take measurements anywhere, outside the laboratory or production hall

Request for a quote

ZETEK SP. Z O.O.

Poland

Serial production of details for the construction of cars, machines or household appliances is associated with the need to maintain a high level of dimensional precision. Especially in the case of machines and components in motion, their parts must be perfectly matched so that they interact without causing friction and accelerating the rate of wear. That is why systematic CMM measurements performed with the use of special coordinate measuring machines are so important. These machines are equipped with three measuring systems enabling simultaneous measurements in the XYZ coordinate axes. An additional element is a probe that allows you to locate the surface of the measured element. CMM coordinate measurementsthey take place automatically and are made with the use of CNC technology, also commonly used in precise CNC machining . Such production tests are characterized by very high accuracy and are not exposed to errors resulting from human physical limitations or his subjective approach

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Calibration of measurement instruments - Import exportNumber of results

3 ProductsCompany type

Category