- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automotive industry

Results for

Automotive industry - Import export

CMPLAST

Poland

Occurs in three basic versions PE 300, PE 500, PE 1000. Due to its many advantages, polyethylene has found a wide application in today's modern machine industry. Its very good cutting properties make it a series of various machine parts that work primarily in the bottling, food, chemical, cosmetics and automotive industries.

Request for a quote

CIMAT

Poland

A vertical spindle High accuracy and efficiency are guaranteed thanks to special automatic (or manual) collet adapters with the highest clamping repeatability Onsite drilling or welding stations for mass correction Compensation of unbalance caused by eccentricity of adapter clamping We’ve made component marking obsolete—our machines use the latest rotating speed measuring systems Software converts amount of unbalance into value of mass to remove or add Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

CMTTWV2M—an automatic balancer for turbine wheel of a turbocharger, which can be equipped with a manipulator for component loading and unloading. The machine is equipped with the latest, most costeffective milling station technology. The unique feature of the CMTTWV2M is that it can balance a wide range of turbine wheel weights—the weight range of the balancer is wider than similar machines on the market. Air bearing technology is a standard feature on the CMTTWV2M. CMTCWV2M – automatic balancer for compressor wheel of a turbocharger, which can be equipped with a manipulator for component loading and unloading. The machine is equipped with a latest cost effective milling station. The unique feature of this machine is that it can balance the widest range of weight on the market today. Air bearing technology is applied as a standard feature. CMTCWV2—a manual balancer for the compressor wheels of a turbocharger for R&D departments and small scale productions.

Request for a quote

CIMAT

Poland

Suitable for a manual operation by operator, Suitable for an automatic cell with a robot load/unload, Suitable for an automatic conveyor production, Wheel presence sensors, Imbalance compensation of a spindle, Ergonomic size of the machine, Sophisticated fluids drain system with reservoir, Spindle protection system from metal chips, Automatic clamping of a wheel hub with a heavy duty pneumatic clamping chuck, Automatic brake and wheel positioning, Fastest balancing cycle time, Fastest tool changeover time, Made of wellknown brands heavy duty components, Servomotor as a spindle drive motor, Software capabilities Valve compensation feature, The best quality, automatic display, Password protection access for operator and shift manager, Any language possible, Industry 4.0 compliant, Static and dynamic imbalance display, Autotest and selfcalibration, Data transfer and communication with master station, CSV file data creation Sophisticated remote diagnostic and support software .

Request for a quote

CIMAT

Poland

High accuracy and efficiency are guaranteed thanks to special software that distributes unbalance to different counterweights for drilling. Onsite drilling station that can travel in different directions and provides fast and easy mass correction. Custom balancers are available upon request. Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant. Permanent calibration and rotor specific calibration as standard Latest measuring and control unit ROTORTEST based on microprocessor technology

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIMAT

Poland

Machinery Directive 2006/42/EC compliant Custom balancers are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST Balancing reports are saved as a PDF, CSV or XLS, printed on a builtin printer or sent to an ERP system Safety norms ISO 21940232012 (old ISO 7475 and DIN 45690) compliant CIMAT’s software converts amount of unbalance into predefined special balancing clips, which have to be placed on a blade according to the onscreen information Power supply connectors are connected to the motor of the fan automatically

Request for a quote

CIMAT

Poland

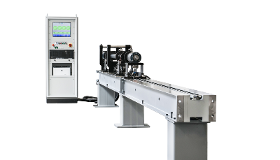

CIMAT offers two types of special balancing machines for drive shafts The CMT250WN Serwis, designed for mediumscale manufacturers, and the CMT250WN, designed for large scale manufacturers. Our advanced measuring unit, the ROTORTEST 9.5, is equipped with an LCD touch screen that displays balancing results and utilizes the latest software, making operation easier than ever before. You can even save data on external storage via a USB port, send it via wifi or ethernet, or print the balancing reports out with a builtin laser printer. Main Features Ability to balance in four correction planes at the same time Accurate and efficient Intuitive and easy to operate software Reinforced external pedestals designed to withstand high axial loads on the splined connector The middle pedestals of the machine are specially designed to accept the support bearings of a drive shaft, without needing to disassemble

Request for a quote

CIMAT

Poland

Automated Balancing Machines for Brake Discs and Drums Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

High accuracy and efficiency are guaranteed thanks to special automatic (or manual) collet adapters with the highest clamping repeatability. Compensation of unbalance caused by eccentricity of adapter clamping. We’ve made component marking obsolete—our machines use the latest rotating speed measuring systems. Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request. Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690)compliant. Permanent calibration and rotor specific calibration as standard. Intuitive and easy to operate software. Latest measuring and control unit ROTORTEST based on microprocessor technology. Different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights.

Request for a quote

CIMAT

Poland

Automated Balancers for Rotors of Supercharger Machinery Directive 2006/42/EC compliant Custom balancers are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quoteResults for

Automotive industry - Import exportNumber of results

11 ProductsCompany type