- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastics conversion

Results for

Plastics conversion - Import export

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

SMART STRETCH TECHNOLOGY – INTELLIGENT USE OF SPACE. SMART STRETCH TECHNOLOGY – means flexibility in widening the work area in optimal harmony with your processing workpiece, while maintaining the same, cost-optimized machine size. Variable spindle distances in the X axis within the MFZ 7 Adaptation of the workspace design to the machining workpiece Lower machine investment costs thanks to workspace flexibility Lower additional production costs due to optimal machine installation space Shorter delivery times thanks to modular machine design Ecological, because only as much “machine” is manufactured as is required for your workpiece Higher productivity by increasing the number of spindles with the same working space per spindle in the same machine size Definition of the machine by the workpiece and not by the spindle distance

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

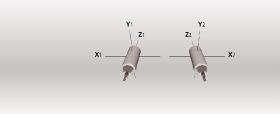

2-SPINDLER WITH TWO INDEPENDENTLY CORRECTABLE 3D UNITS (X, Y, Z) FOR HIGHEST PRECISION WITH CRITICAL TOLERANCES. COMPARABLE TO TWO 1-SPINDLE MACHINING CENTERS STEREO 3D SETUP – CONSTRUCTIVE DECOUPLING OF THE 2-SPINDLE SYSTEMS. 2-spindle with two independently correctable 3D units (X, Y, Z) Highest precision for critical tolerances Comparable to two 1-spindle machining centers Easy tool setup and lower tool costs New range of workpieces - finish processing of complex components Minimal setup time for new workpieces

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

The particularly short distance of the unique DOUBLE BALL SCREW DRIVE from SAMAG increases the rigidity and thus the machining accuracy immensely. Compared to traditional drive concepts, the TFZ concept is up to 27 times stiffer and more precise. Reduction of vibrations on the drilling and milling unit through DOUBLE BALL SCREW DRIVE and POWER TOWER DESIGN, this is how it works: Second ball screw with additional guide and second pivot bearing on the rear rail (V) Upstream double-guided and particularly strong ball screw drive of the X-axis Minimum distance (l) between tool tip (TCP) and front swivel bearing (A) 1-spindle concept guarantees short, stable tools with excellent accessibility to the workpiece and the machining point Generously sized work spindle to achieve maximum performance parameters Stiff milling spindle with additional, patented support Variable steady rest positioning system to increase drilling accuracy with spacer between spindle and steady rests

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Machining time on 3-spindle solution 97s Right and left workpieces are produced in the same machine

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Processing time less than 80s per workpiece possible Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2006, extensive manufacturer overhaul in 2021 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2006 Extensive manufacturer overhaul 2021 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm KSM rotary union with electronic leakage monitoring Chip conveyor Knoll (scraper belt conveyor in positioning variant along the machine, ejection height 1,200mm)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

3 or 4 spindle machining Complete processing on MFZ Processing time less than 55s per workpiece

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Conversion Super Kit Related Links Online Catalog QuickShip Program Literature Order Center Video Library Related Products DM Advantage Two-Speed Fan Drives PolarForce Two-Speed Conversion Kits DM Advantage Reman Fan Drives DM Advantage Repair Kits WindMaster Fans WM Revolution Fans WindShift Modular Fans Featuring superior components, the DM Advantage Conversion Super Kit converts a standard DriveMaster® On/Off Fan Drive to a DM Advantage On/Off Fan Drive. The kit is easy to install and includes a premium double row angular contact (DRAC) sheave bearing, an improved air cartridge seal that provide 40 percent longer life, and a long-wearing friction liner for added reliability and reduced maintenance. Like all Genuine Horton Super Kits, these kits contain everything needed to completely rebuild your fan drive. Once converted, the DM Advantage On/Off Fan Drive has the latest innovations and a fail-safe design for long-life performance. Benefits - High-performance and efficient engine cooling - Increased reliability in high-horsepower applications - Easy to install and maintain Features - The latest innovations - A premium double row angular contact (DRAC) sheave bearing - Improved air cartridge seal - Long wearing friction liner Applications - Heavy-duty trucks - Medium-duty trucks - Buses - Off-highway equipment Premium Bearing vs. Groove Hub Bearing Related Products - DM Advantage On/Off Fan Drives - DM Advantage Two-Speed Fan Drives - PolarForce Two-Speed Conversion Kits - WindMaster Plastic Fans - WindMaster Revolution High-efficiency, Hybrid-flow Fans - WindShift Modular Fans Links - DM Advantage Training - Order or View Literature - On-line Catalog

Request for a quoteResults for

Plastics conversion - Import exportNumber of results

11 ProductsCountries

Company type