- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic press

Results for

Plastic press - Import export

NORELEM FRANCE

France

The pressed in plastic inserts offer optimal damage protection for sensitive workpiece faces.

Request for a quote

NORELEM FRANCE

France

Tempered and black oxidised. Note: The pressed in plastic inserts offer optimal damage protection for sensitive workpiece faces.

Request for a quote

SPIROL

Germany

Offered with or without a head, Straight Pins are distinguished by their uniformity. The chamfered ends are more consistent than tumbled edges—making installation with automatic assembly equipment more reliable. Straight Pins are retained by compressing the host, not the inflexible solid pin. They are suitable for use in plastics for press-fit applications limited to those cases where the host material can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). Straight Pins are often used to replace Ground Dowels in applications that do not require the tight tolerances of a Ground Dowel.

Request for a quote

SPIROL

Germany

SPIROL's BP100 Press-N-Lok™ Pin has opposing barbs on each end of the pin and is designed to permanently retain two plastic components to each other such as two halves of a plastic enclosure. Press-N-Lok™ Pins are installed in two stages: First, press the pins into one half of the plastic housing. Next, align the other half of the housing with the exposed pins and press into place. During installation, the plastic will backfill into the area around the barbs resulting in maximum resistance to axial force. SPIROL's Press-N-Lok™ Pins are manufactured from lightweight, lead free aluminium as a standard, and available to order in austenitic stainless steel. BP100 Press-N-Lok™ Pins are available in diameters ranging from 2mm to 4mm.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of all important parts Maintenance of mechanical and industrial machines Advantages and benefits Long and strong hand lever with plastic grip Grease press barrel smooth and without internal profiling Stable grip at the plunger rod that prevents bruising Grease press barrel and rear cover form a unit (in order to prevent accidents) Limit stop for the plunger rod Mounting of firm nozzle tubes easily possible Suitable for grease up to NLGI 3

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

BÜRKLE GMBH

Germany

Bürkle’s mercury collector enables the easy collection of spilt mercury, which can then be used again. The mercury collector is composed of a tub with a screw cap lid that has a special plastic foam inserted. On pressing this foam gently on the spilt mercury, the foam’s pores are opened and the mercury globules are absorbed. The cap is then screwed on the tub, the globules are released again and fall through the perforated separation into the tub.

Request for a quote

MACFAB SYSTEMS LTD

Ireland

The MACFAB 150 baler is a popular model for small retail outlets and supermarket chains. This vertical baler is an excellent option for businesses to recycle the cardboard boxes and plastic wrapping film waste generated from incoming goods. The baler makes a compact bale of 150 KG and is mechanically ejected onto a pallet for collection by the recycling company. Bales are tied using 4 rolls of bale strapping. This baler has many customization options available including two different types of operator controls, two different loading door options, various colour options and different single phase and 3 phase power supply options.

Request for a quote

MACFAB SYSTEMS LTD

Ireland

This small baler is perfect if you are a smaller producer of waste with limited space available in your storage area. Ideal for small cardboard boxes, plastic wrapping film, and paper. The 40 baler makes a 40 kg bale of cardboard. The baler is easy to setup and operate and includes a lifting trolley to eject the waste bale from the baling press. As standard this machine comes with a 13-amp single phase 220-volt power supply. Other power supply options are available upon request. A small table insert can also be purchased which can then crush small food steel cans.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Hot press for making sheet from plastic granules, 7inch touch panel, pressure monitoring, water cooled heating plates

Request for a quote

HIDROMEC SRL

Italy

Hydraulic cylinder applications in the stationary industrial sector are diverse: hydraulic presses of all kinds, ranging from presses for sheet metal forming and presses for the plastics industry to filter presses and scrap presses. Roll forming machines are also included, as well as machines and industrial equipment of various kinds. Equipment in constantly changing shapes and sizes gives us the opportunity to apply the design know-how we have acquired over forty years of dedication to meeting a wide variety of customer requirements. Hidromec develops hydraulic cylinders and systems for equipment with applications in the industrial sector that are powerful, durable and comply with the relevant environmental standards.

Request for a quote

PIR.SA.FA. S.R.L.

Italy

Our Company produces 100 mm coffee stirrers and 110 mm cappuccino stirrers, bulk packaged in bags. The materials used (food-grade and compliant with the MOCA regulation concerning Food Contact Materials) are: PS or PLA, in white or coloured version (food-grade pigments compliant with the MOCA regulation concerning Food Contact Materials). Each of the packaged bags are electrically welded: total absence of glue. The machines and equipment used for the production of highly innovative stirrers (moulds treated to avoid the use of lubricants and without plastic waste; electrical injection presses without hydraulic oil and with low energy consumption) together with highly qualified personnel for accurate control of production, ensure high standards of quality, safety and hygiene of products in compliance with current industry legislation.

Request for a quote

ISIM GELISIYOR CONSULTANCY

Turkey

Our Capabilities in our factory: a. Custom Design and Production: We produce your products labeled with your own LOGO. b. Quality: We always follow the international standardization rules. c. Raw Material: Our company uses high-quality material with various colors such as ABS, PS, PP, APET, PVC, PET, PETG, HIPS, etc. d. Technology: CAD design sketches, custom colors according to international codes. e. Complete Solution: We provide complete solution for your custom design, sample producing, mass production, quality inspection and delivery. f. Generally used but not limited in automotive, medical, food & agricultural machines, advertising tools, yacht & marine, heating & cooling, furniture, toys, packing industries, and all other industrial designs and stands. Industries/Products Automotive, Medical, Food & agricultural machines, Advertising tools, Yacht & marine, Heating & cooling, Furniture, Toys, Packing, Caravan Components, All other industrial designs and stands.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ozkoc started business with mass production of first plastic injection presses in Turkey. In the 1970s, by shifting his knowledge and experience on thermoplastic materials to thermoset materials, Ozkoc started to produce melamine presses. With the experience of this field Ozkoc started produce presses for rubber, bakalite, linings and similar resin based thermosets. Same presses also could be used for different materials thanks to the flexible automation.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ozkoc started business with mass production of first plastic injection presses in Turkey. In the 1970s, by shifting his knowledge and experience on thermoplastic materials to thermoset materials, Ozkoc started to produce melamine presses. With the experience of this field Ozkoc started produce presses for rubber, bakalite, linings and similar resin based thermosets. Same presses also could be used for different materials thanks to the flexible automation.

Request for a quote

GEISSEL

Germany

wege® - the flexible cable gland system in brass, stainless steel and plastic. wege® M Pressing-screws with strain relief. Material: brass nickel-plated,screws: stainless steel, thread: M12-M32, PG9-PG48

Request for a quote

GEISSEL

Germany

wege® - the flexible cable gland system in brass, stainless steel and plastic. wege® M Pressing-screws with strain relief. Material: brass nickel-plated,screws: stainless steel, thread: M12-M40, PG7-PG48

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEISSEL

Germany

wege® - the flexible cable gland system in brass, stainless steel and plastic. wege® M Pressing-screws. Material: brass nickel-plated, thread: M12-M63, PG7-PG48

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

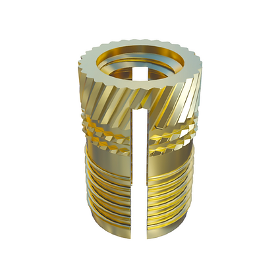

The PRESS-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoplastic materials The combination of flat and knurled areas ensure high torque and pull out performance normally achievable only with inserts that are installed by a hot/ultrasonic process These inserts are installed by simple pressure, without need for special equipment Also known as PRESS-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The EXPANSION-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoset plastics Due to its diamond knurled design, this insert penetrates for a minimum length within the hole walls without decreasing tensile strength. This feature makes it ideal for applications in hard thermoset plastics They are recomended for applications where high resistance values are not required They are installed by simple pressure, without the need for special equipment Headed (flanged) and reverse-headed (reverse flanged) versions are also available. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In inverted flange inserts, a screw can be inserted on the opposite side of the flange, offeing very high pull-out resistance Also known as BANC-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S50, S51 are press-in inserts to be installed into cylindrical holes Suitable for soft thermoplastics The helical knurl of the outer surface is specially designed to facilitate insertion by allowing maximum plastic sliding of the material in the serration grooves They allow easy and low-cost assembly, as no special machinery is required Offer moderate pull-out and good torque resistance They are available in unheaded S50, and headed (flanged) S51 versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In the S51 a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications The S50 in addition are symmetrical so they do not need to be oriented during installation process.

Request for a quote

CBG COMPOSITES GMBH

Germany

fako® Sealing putty 3765, made of butylrubber, has been developed as a supplement to the fako® Sealing strip 3714, for most sealing purposes where absolute resistance to ageing is required and for which an intermediate layer of 0.8 mm to 1 mm has to be used. In combination with the Sealing strip 3714 most desired thickness’s can be obtained for seals. The putty does not become hard but remains plastic and elastic. To fulfil its requirements the putty has not only to be elastic but also plastic so that, when pressed, it will penetrate into any gaps and remain, thus forming a complete seal. Technically this is only possible through a combination of two basic materials with the same chemical composition but with different molecular weights. With two components the above requirement is met for both sufficient penetration depth and stability of the kit at the same time. By simple filling with a putty knife, you can obtain a min. thickness of approx. 0.2 to 0.3 mm. Priming is not required.

Request for a quote

MÜLLER MARTINI AG

Switzerland

The EMP 513 casingin machine is suitable for casingin straight and rubbeddown book blocks at up to 30 cycles per minute. The book blocks can be inserted in rigid, flexible or plastic covers and are then pressed. The joint is also formed cleanly.

Request for a quote

GIZELIS ROBOTICS

Greece

All industrial units feature standardized and repetitive, e.g. press-brakes, plastic or metal moulding, product re-orientation, CNC feeding etc. Industrial robots are extensively used in these applications as they offer much higher productivity. Precision in product placing is top-notch and provides for end-product consistency, whereas machine downtimes are eliminated. Thanks to their manufacturing, robots may operate even in clean rooms and -contrary to manpower- they may handle products without running the risk of bacterial infection, thus reducing production costs even more (no need for sterilization ). Robotic flexibility allows for no limitations in the tasks undertaken and enables cooperation with all machinery of an industrial unit.

Request for a quote

MIR ARENA

Turkey

Manufactured from PE and PP According to EN ISO 4892-2 standard anti UV additive Corrosion resistant in compliance with EN ISO 9227 Standard In compliance with EN ISO 11925-2 and 13501-/E class fire-resistance In compliance with EN ISO 13200-4 Standard highly resistant to hooliganism Tip-up mechanism of the product operating with the center of gravity system The metal parts of the seats are designed and produced by laser cutting without seamless of monolithic 6 millimeter sheet and bending in press molds Plastic weight of the seat is 3,250 gr and total weight of the seat is 9,540 gr The back and the seating part of the product is manufactured from leather upholstered polyurethane foam

Request for a quote

CRE VERZENI COMPANY

Italy

C.R.E. di Verzeni is a certified firm, leader in the production of heating elements for over 50 years. Our experience and skills allow us to establish not only in the Italian market, but also worldwide. Thanks to the purchasing of new machinery technology we have increased our quality standards while reducing production costs. This guarantees our clients, quality at competitive prices. We are official distributors for the main machinery manufacturers of: •Plastic, rubber (press, blow, extrusion, injection etc.) •Chemical/Pharmaceutical •Food (dryers and mixers) •Packaging •Water sector •Etc. C.R.E. di Verzeni is characterized by: One of the best quality on the European market--we got UNI EN ISO 9001-2000 certification Italian design with customized products Good quality/price ratio Fully made in ItalyProduction times: 7 days after your order and if urgent up to 24hours after the order (depends on the type of heater). On our website www.creverzeni.com

Request for a quoteResults for

Plastic press - Import exportNumber of results

27 ProductsCountries

Company type

Category

- ELECTRIC EQUIPMENT (4)

- Tools & Hardware (3)

- Presses, hydraulic (2)

- Screw cutting - steels and metals (2)

- Waste sorting - machines and equipment (2)

- Auditorium seats (1)

- Clamp collars, plastic (1)

- Food industry packaging machinery (1)

- Handling - Machines & Equipment (1)

- Heating, industrial - installations and equipment (1)

- Hydraulic equipment (1)

- Laboratory equipment and instruments (1)

- Plastic products for the garment industry (1)

- Plastic products for the medical industry (1)

- Printing and setting - machinery and equipment (1)

- Seals and packing material (1)

- Silicones (1)

- Steel, special (1)

- Testing equipment (1)