- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plasma- atmospheric

Results for

Plasma- atmospheric - Import export

BSI CLEANING

Luxembourg

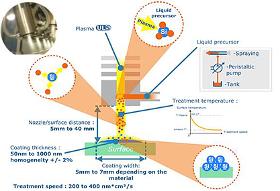

Due to the combination of materials forming them (polymers, glass, metals etc.), composites have complex surface properties. Atmospheric plasma opens the way to a high-quality surface finish as it allows cleaning and activation in a single stage, facilitating processes such as painting and varnishing. As an ecological and efficient technique, plasma is able to replace the most common toxic treatments. Advantages: - Uniform treatment easily integrated into both automatic and manual production. - delicate care of the part to be treated - Easy to implement, rapid treatment - Complete elimination of wet chemical products in the cleaning process - No neutralisation of the waste water, no elimination costs - No heat or steam generated in the workplace - Highly reliable and efficient cleaning process - Marked improvement in hydrophilic properties - Less staff required

Request for a quote

BSI CLEANING

Luxembourg

The aim of the activation process is to alter the nature of a surface or its energy. More often than not, this allows the wettability of a surface to be increased (by adding polarity) or encouraging the adhesion of a coating (paintwork, ink, glue, varnish). Plasma activation is a simple process that allows a wide range of improvements. Plasma pre-treatment allows, in one single, simple and cheap stage, a significant improvement to the surface to be achieved.

Request for a quote

BSI CLEANING

Luxembourg

- Powerful and focused treatment - Used in the open air - Quick and cold - Works with compressed air - Manageable and easy to use - Compact generator and tube - Simple to integrate

Request for a quote

BSI CLEANING

Luxembourg

- Wide process from 6 cm to 50 cm - Uniform plasma curtain - 3D treatment - Very low treatment temperature - Work with nitrogen - Manageable and easy to use - Easy to integrate

Request for a quote

BSI CLEANING

Luxembourg

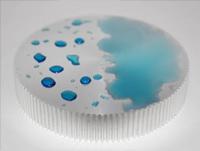

- Very fine layer of SiO2 or SiOx - Used in the open air - Quick and cold - Compact generator and tube - Simple to integrate

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the atmospheric pressure plasma system PlasmaBeam RT, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 120 mm, substrates can be treated locally with precision. With our new product, the PlasmaBeam RT, there is now the perfect solution for fast, efficient and wide in-line plasma treatment of 2D surfaces. The RT can be perfectly integrated into existing production lines and thus enables the automated cleaning and activation of various components and web-shaped materials. We create the possibility of up to 120 mm wide plasma treatment, with the usual consistent quality and effectiveness of atmospheric pressure plasma systems from Diener electronic.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the atmospheric pressure plasma system PlasmaBeam Mini, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 3 - 5 mm, substrates can be treated locally with precision. In contrast to the Plasmabeam devices, the PlasmaBeam Mini is designed for laboratory use. The PlasmaBeam technology enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam DUO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam PC atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam PC is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam QUATTRO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam QUATTRO is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam DUO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the APC500. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 is only suitable for non-conductive materials. PlasmaAPC 500 is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500: Plastics, rubber, ceramics, glass.

Request for a quoteResults for

Plasma- atmospheric - Import exportNumber of results

14 ProductsCountries

Company type