- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- piston dosing

Results for

Piston dosing - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

For SIP (Sterilization In Place), the MANOY® AS dosing piston is fed into the washing hole, which must be designed so that the piston has sufficient expansion capacity during SIP at +140°C to avoid damaging its functionality and shortening its life. After the cleaning process the MANOY® AS dosing piston may only be moved into the dosing hole when a temperature close to the operating temperature (operating temperature +20 °C), and not to exceed +80°C, has been reached. A feed cone into the dosing hole of 10° max. and rounded edges are essential.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

For CIP (Cleaning In Place), the MANOY® AS dosing piston is removed from the dosing hole. A simple vertical wash in the hole is suitable and sufficient. After the cleaning process the MANOY® AS dosing piston may only be moved into the dosing hole when a temperature close to the operating temperature (operating temperature +20 °C), and not to exceed +80°C, has been reached. A feed cone into the dosing hole of 10° max. and rounded edges are essential.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Electronic piston dosing pump FEDOS DX The microprocessor-controlled FEDOS DX combines the proven features of the FEDOS series with the latest requirements in dosing technology. Ideal for applications that require integration of the pump into control systems or control loops, the FEDOS DX offers versatile adaptation to various control signals and system monitoring. Main features: Performance range: 0.17 to 31.5 l/h, up to 100 bar Flexibility: Adjustment of the stroke frequency by division or multiplication Precision: Suitable for precise mixing tasks Independence: Low dependence on back pressure Efficiency: Linear change in dosing quantity with the stroke length Ease of use: Plunger drive with easy-to-operate power adjustment Optional: Rinsing lantern The FEDOS DX is the ideal choice for precise dosing applications that require high accuracy and adaptability.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is a professional manufacturer of ceramic metering pump. The material we made for ceramic plunger pump is 99% alumina and zirconia, made by CIP forming and then with precision processing.Our business expanding in high-tech filling solutions for precision liquid filling in 2015, offer high grade accuracy, precision and durability. They are utilized in a broad range of Medical, Laboratory, Analytical and Industrial Process applications. All our ceramic filling pump products are Food Grade. There are three types of pump modules: Rotary, Linear and Multiplex which are used for different applications depending upon the customer's fluidic needs.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The FEDOS E is the latest development in the FEDOS series, combining proven features with modern dosing technology requirements. It offers improved flexibility and efficiency in process engineering applications. Piston dosing pumps are robust and accurate, ideal for precise liquid dosing in various industries. Their simple mechanism ensures reliability and durability. Key features: . Precision: Accurate dosing . Robustness: Durable and resistant . Flexibility: Processes different liquids . Easy maintenance: Easy to maintain Piston dosing pumps are ideal for applications that require high accuracy and durability.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Piston diaphragm dosing pumps are particularly precise and pressure-independent dosing devices. The dosing quantity changes proportionally to the stroke length and can be set reproducibly down to the smallest quantities. For this reason, twin and multiple piston pumps are particularly suitable for precise mixing tasks in which a constant ratio of different media, which can be set as required, must be metered. The total quantity can be infinitely varied from 5% to 100% at a constant ratio using externally adjustable drive motors. Heated heads allow the dosing of cold, rigid media. An optional flushing lantern can be used to prevent harmful leaks and to protect the packings and pistons against abrasive substances.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic metering pump is widely used for many famous brand filing machine. We can make customized shape and size of ceramic filling pump according to clients design request. Product Application: Applicable in quantitative subpackage with high level of hygienerequirement like injection oral liquid etc. Widely applied to pharmaceutical equipments of famous enterprises BOSCH, B+S, IMA, GROENINGER, INOVA company and Trucking Technology, Miaxis, Qianshan etc. CERAMIC FILLING PUMP FEATURES: Liquid non-polluting, High precision Long service life, Very high surface finish High hardness, Wear resistant Particle release is extremely small Water absorption as low as zero Minimal friction, Minimal residual Low thermal expansion coefficient Inert Chemical stability, Acid corrosion resistance Resistant to high temperature, Piston clearance fit more Filling accuracy can be achieved online cleaning and sterilization

Request for a quote

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available syringes nested in tubs and bags Aseptic fields of application Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional

OPTIMA PHARMA GMBH

Germany

1-lane supply Aseptic fields of application Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Intermittent operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Do you sell or make similar products?

Sign up to europages and have your products listed

FIS MODULAR SYSTEMS LTD.

Russia

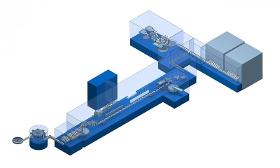

The modern plunger (piston) dosing system for liquid confectionery masses (marmalade, jelly, creams, soufflé, hot chocolate, etc.) supports dot depositing and dotted line depositing. It is designed for depositing or pouring into molds and special hollows in products of liquid food masses. IntelleDrop can be used both as a stand-alone module for filling molds with marmalade, decorating cookies, or injecting profiteroles, and as part of the CreaSweet complex with installation on the IntelleBase module. It comes with a binary gelling section. You can use the machine with rotary ovens (and you still can upgrade it to work with a tunnel oven).

Request for a quoteResults for

Piston dosing - Import exportNumber of results

19 ProductsCountries

Company type