- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pir panels

Results for

Pir panels - Import export

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

FRIGO SYSTEM

Turkey

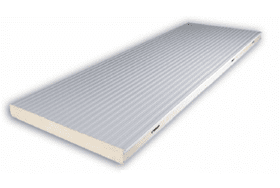

Cold Room panel polyurethane density of is 42 kg / m³ (± 2) and they are produced with PUR or PIR insulation. Cold Room Panels are interlocking in male and female form and with eccentric lock and can be disassembled when necessary. Wall and ceiling panels are produced in thicknesses of 60, 80, 100, 120, 150, 180, 200 mm. Dip galvanized sheet painted with polyester-based paint in 0,50 mm thickness with RAL 9002 color code is used for both surfaces of the wall panels. Wall and ceiling panel sheets are produced in Stainless Steel, PVC and PPGI depending on the area of use. The surface of the panels is smooth, hygienic and easy to clean. Panels are prevented from heat loss with their special design and accessories. Panels with surface protection film are protected against scratching during transportation and assembly. Panels can be manufactured with flat or corrugated surfaces.

Request for a quote

BOKKA SP. Z O.O.

Poland

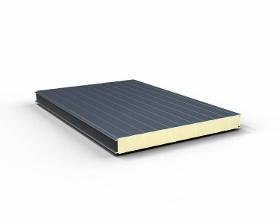

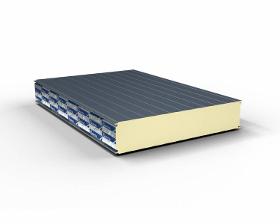

We offer wide range of innovative wall, roof or cooling layered boards containing the core made of polyisocyanurate foam (PIR). These boards consist of two linings made of steel sheets galvanized on both sides, with organic polyester lacquer coating of 25 µm and the s tructural and insulation core made of rigid, Freon-free, self-extinguishing PIR foam with great thermal insulation and fire resistance. Thermal conduction coefficient is λ = 0.022 W/m*K. PIR foams are characterized by strengthened resistance against high temperatures, they decompose at temperatures over 325ºC and their carbonization is ca. 50%. The carbonized layer protects against penetration of high temperatures through a board resulting in more efficient fire protection barrier. Diversified colours and profiles result in various possibilities for architects.

Request for a quote

BOKKA SP. Z O.O.

Poland

We offer wide range of innovative wall, roof or cooling layered boards containing the core made of polyisocyanurate foam (PIR). These boards consist of two linings made of steel sheets galvanized on both sides, with organic polyester lacquer coating of 25 µm and the s tructural and insulation core made of rigid, Freon-free, self-extinguishing PIR foam with great thermal insulation and fire resistance. Thermal conduction coefficient is λ = 0.022 W/m*K. PIR foams are characterized by strengthened resistance against high temperatures, they decompose at temperatures over 325ºC and their carbonization is ca. 50%. The carbonized layer protects against penetration of high temperatures through a board resulting in more efficient fire protection barrier. Diversified colours and profiles result in various possibilities for architects.

Request for a quote

BOKKA SP. Z O.O.

Poland

We offer wide range of innovative wall, roof or cooling layered boards containing the core made of polyisocyanurate foam (PIR). These boards consist of two linings made of steel sheets galvanized on both sides, with organic polyester lacquer coating of 25 µm and the s tructural and insulation core made of rigid, Freon-free, self-extinguishing PIR foam with great thermal insulation and fire resistance. Thermal conduction coefficient is λ = 0.022 W/m*K. PIR foams are characterized by strengthened resistance against high temperatures, they decompose at temperatures over 325ºC and their carbonization is ca. 50%. The carbonized layer protects against penetration of high temperatures through a board resulting in more efficient fire protection barrier. Diversified colours and profiles result in various possibilities for architects.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HII

Turkey

Sandwich panel press Sandwich Panel Production Line Our contionuous PUR / PIR sandwich panel production line is already recognized its value by exporting to European country with CE and other major sandwich panel producing companies at domestic and foreign, DMMET, we will keep trying for development in accordance with customer’s needs for the high quality sandwich panels. APPLICATION of the PU-PIR PANEL PRODUCTION LINE This production line is suitable for manufacturing socket type ( wall plate panel ) and lapped type ( roof tile panel ) pu sandwich panels. FLOW CHART Uncoiler - Feeding Guide - Protective Film Coating - Roll Forming Machine - Rolling Conveyer - Steel Pre-Heating - Foaming Machine - Double Belt Pressing Machine - Rolling Conveyer - Auto Fly Cutting To Length - Runout Table - Auto Vacuum Stacker - Auto Packing Machine MAIN TECHNICAL DATAS Production Type : Continuous and automatic production Specification of Metarial : 0.3 - 0.

Request for a quote

BRIMAN POLYURETHANE

Turkey

POLYOL FOR PIR SANDWICH PANEL

Request for a quoteResults for

Pir panels - Import exportNumber of results

8 ProductsCountries

Company type