- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipe rotation

Results for

Pipe rotation - Import export

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

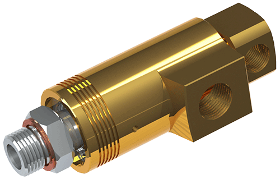

single inlet/outlet line or combined inlet/outlet line with stationary or rotating syphon pipe brass (rotor stainless steel) small diameter ceramic seal CDCartridgeDesign PRESSURE MAXIMUM 10,0 bar water TEMPERATURE MAXIMUM 90 °C water SPEED MAXIMUM 1000 1/min NPT thread 3500 1/min ISO 228 thread SIZEDN 10 (3/8") DN 15 (1/2") DN 20 (3/4")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

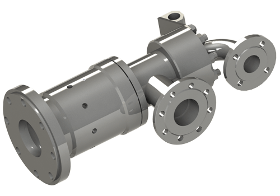

single inlet/outlet line or combined inlet/outlet line with stationary or rotating syphon pipe universal usecooling, heating, clamping series with ball bearings, graphite bushbearing or solid grease ballbearings bellows sealing available in stainless steel CDCartridgeDesign PRESSURE MAXIMUM 6,0 bar heat transfer oil 10,0 bar air nontoxic gases steam 17,0 bar water TEMPERATURE MAXIMUM 300 °C air heat transfer oil nontoxic gases steam vacuum water SPEED MAXIMUM 600 1/min DN 80 (3") DN 100 (4") DN 125 (5") SIZEDN 80 (3") DN 100 (4") DN 125 (5")

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The grain thrower PZM-120M is an ideal machine for fast loading of any grain into any transport. PZM-120M grain thrower is also used to transfer grain from one place to another. During the transfer process, moisture and light impurities are partially removed from the grain. Transfer of grain is necessary during its long-term storage. PZM-120M grain loader quickly loads grain into grain carriers, automobiles, railway cars, containers, barges, trailers, etc. A full load of a grain truck takes about 15 minutes. The grain thrower PZM-120M is used to work with grain, oilseeds, legumes and industrial crops, while the trauma to the grain is minimal (less than 0.1%). During the operation of the grain thrower, the grain is fed to the conveyor using scraper feeders. The conveyor loads the grain into the trimmer, which throws it through a special guide tube. The trimmer with the pipe easily rotates 257 degrees. Changing the direction and height of grain flight is carried out in less than 3 sec.

Request for a quote

TECHNIC MACHINES

Turkey

We designed our Semi-Automatic Pipe Bending Machines to have complex pipe bending results easily with servo rotation function during pipe bending process. We can say that our Semi Automatic Tube Bending Machine is economical option of 3 Axes CNC Pipe Bending Machines with lower investment than CNC Tube Bending Machine. General Details - Servo Rotation - NC Control - Direct Gear Transmission - Touch Screen - Hydraulic Clamp-Die/Pressure-Die - Automatic Mandrel Extraction - Adjustable Flip Stops - Quick Changeable Tooling - Automatic / Manual Mode - Warning Messages - Energy Saving Mode Technical Details Tube Bending Diameter Range from 6 mm to 130 mm Ø Pipe Bending Machine Center Line Radius According to Demand Max. Tube Bending Angle 190°

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

TR-0103 Turning roll with standard control box. TR-0104 Turning roll with digital control box. 1. Turning roller, the best solution for big tank welding. 2. For pipes or vessels rotation. 3. Metallic rollers bounded with polyurethane. 4. High frequency protected. *CE Conformity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Capacities range from 1,000 to 6,000 kilograms. 2. For pipes or vessels rotation. 3. Metallic rollers bounded with polyurethane. 4. Quick, accurate roll centering adjustment. 5. High frequency protected. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

The Ocut series provides unmatched performance, reliability, and flexibility in thermal cutting production environment. 1.Cutting diameter from 50~900mm 2.Working length 6000mm or 12,000mm 3.Support straight or bevel plasma cutting. 4.Rotation with self centering pipe fixture. 5.Height adjustable rotator. Save/Load each job's rotator height. 6.High torque drive system. 7.Dustproof high precision linear guide ways. 8.Self-aligned plasma torch collision holder. *CE Conformity

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

The extensive power spectrum of this solid production series in combination with the standard equipment coordinated optimally sets new standards in cleaning technology. The solid interpretation of the machine components connected with the modern design of the easy-care machine case completes the innovative machine concept. By the choice of specific accessory articles many possible applications open up. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Modern design Powerful washing pump High permissible basket load Low water pressure switch as dry-run protection Tank cover in the return flow, filterbasket incl. Programmable operation operating counter incl. Housing insulation Loading carriage incl. Grate bearing Digital temperature indication Electronic basket drive (PF 100; PF 150) Square blast pipe system (PF 200) Rotation blast pipe system (PF 300) Adjustable feed

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Filling and mixing lines: Filling and mixing line, height and laterally adjustable Filling and mixing line, with removable mixing nozzle Mixing tube made of hard PVC, rotatable with 1 pipe clamp Filling and mixing line, galvanised steel, can be rotated using socket spanners, height and laterally adjustable mixing nozzle Mixing tube made of completely from hard PVC with flange connection with 1 pipe clamp Mixing tube made of completely from hard PVC with flange connection, height and laterally adjustable mixing nozzle with 1 pipe clamp Mixing unit completely galvanised, rotatable, height adjustable with clamp bracket and flange connection Mixing tube completely galvanised with flange connection, mixing nozzle, height and depth adjustable Mixing nozzle completely galvanised with flange connection, fixed mixing nozzle Tank filling line completely galvanised, fixed mounting, 360 degrees rotatable with flange connection Coupling parts,...

Request for a quote

MONFORT

Belgium

Integrated GPS System Autolub lubcore Boom: 2.9 m Hammer piping Rotator piping Hydr security valves Hydr quick attachment Verachter Air conditionning Rear view camera Electrical fuel pump Working lights: 4 front + 1 rear Radio Tracks :800 mm

Request for a quote

KROMA LTD

Serbia

Rotary pressure joint is an assembly which secures sealing between inlet pipe and rotational cylinder thus providing heat transfer by media in or from the equipment's rotational element. Fluids that are commonly used for heat transfer are water, thermal oils, hydraulic oils, cooling fluids and vapor. When it comes to rotary pressure joints, sealing of work fluids is done by the use of mechanical seal. The mechanical seals spring provides contact between sealing faces before the machine starts it's work, while during work, the contact is secured by the act of hydraulic pressure, except in cases of low operating pressures or vacuum. The right choice of mechanical seal is of major importance in order to reach the work of rotary pressure joint efficient , because in cases of mechanical seal malfunction, leakage occurs which reduces efficiency of entire cooling or warming process. “ Kroma Ltd” delivers rotary pressure joints with either single or dual flow.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Colloide provides circular and rectangular scraping systems (plastic and steel) for settlement and flotation tanks. These tanks are generally rectangular or circular, designed to separate solids from the liquid by either settlement or flotation. Circular Tanks We offer two alternatives for circular tanks: -A rotating bridge structure powered by a peripheral drive unit. The bridge supports a frame below it onto which is fixed sludge scraping blades at floor level and a scum blade at top water level. -A fixed bridge mounted on the walls of the tank. A central drive unit rotates the scraping mechanism around the tank, the sludge scraping blades diverting the sludge to a hopper. Rectangular Tanks A chain and flight principle is used for rectangular tanks, consisting of two main chains which move the scraping booms up and down the tanks. When scraping at top water level, the booms push the floated material to one end of the tank, where it is collected by a rotating sludge pipe.

Request for a quoteResults for

Pipe rotation - Import exportNumber of results

13 ProductsCountries

Company type