- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pin mills

Results for

Pin mills - Import export

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

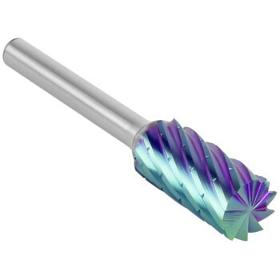

Tyrolit’s tungsten carbide burrs can machine materials like steel, stainless steel, non-ferrous metals, cast iron, and HSS. They come in various shapes and profiles, including tapered, cylindrical, ball-shaped, and special designs for angles, corners, and flutes. The parts are soldered with a copper alloy for impact resistance, enhancing safety and performance. Our burrs ensure first-class grinding with maximum economy, featuring long tool life due to a specially developed cutting edge geometry. The aggressive cutter profile allows for significant material removal in a short time, with reduced heat generation to protect both tool and workpiece, crucial for stainless steel to prevent discoloration. The new HPC-coated tungsten carbide burrs for cast iron, steel, and stainless steel offer higher performance, longer life, and better results. The advanced coating improves chip transport and doubles stock removal, with a distinctive Tyrolit color combination.

Request for a quote

NDS CNC SP. Z O. O.

Poland

CHUCK MILLING PIN TURNING, STEEL S355

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd is specialize in custom machine parts more than 20 years, we have various automatic lathe turning machines can produce small turned parts, especially produce steel pins with low cost and high speed. We have can do further machining and treatments for steel pins, such as milling, grinding, drilling & hardening treatments. Common materials for pins are 35 or 45 steel. The material of the safety pin is 35, 45, 50, T8A, T10A, etc., and the hardness after heat treatment is 30~36HRC. The pin sleeve material can be 45, 35SiMn, 40Cr, etc., and the hardness after heat treatment is 40~50HRC. Pins play a pivotal role in the connection of mechanical components. According to different shapes and functions, it can be divided into: split pin, tapered pin, cylindrical pin, grooved pin, dowel pins,coupling pins, etc. Among the pin products, cylindrical pins, tapered pins and split pins are commodity fasteners that are produced.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

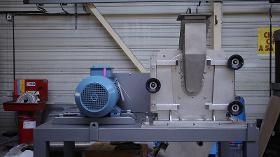

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Fine Mill The solution for fine grinding Ebbecke Verfahrenstechnik AG is your specialist for demanding tasks in the area of ??contract grinding. The fine grinding plants used enable the dissolution of agglomerates as well as the breaking up of solid grain structures including even the very finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Accordingly, they comply with all the strict specifications and hygiene standards of the of food, pharmaceuticals and cosmetics industries. Technical data Target fineness: 1.0-5,000 µm Plant types: Classifier mills, air jet grinding plants, spiral jet grinding plants, pin mills, cross beater mills, hammer mills, Fitzmill, screen mills, disc mills, graters, crushers, cryogenic grinding, nitrogen overlaid plants Product-contacting parts: Stainless steel Delivery in: Bags, bales, Big Bags, octa

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HammerKnife Universal Mill is the combination between a Hammer Mill and an Universal Mill. As the FORPLEX FNG Mill it can be equipped with different grinding tools (hammer plate ou blade plate) which are adjustable in relation to the product to be ground. The FK Mill has the same advantages as the Universal Pin Mill FNG easy to use, easy to clean, easy to maintain, but also simplicity of changing the grinding tools or grids. Perfect for technical applications such as the grinding of natural ingredients (knife rotor designed for the crushing of plants), the FK mill was designed to meet the standards of the foodstuffs industry, fine chemicals industry, pharmaceuticals industry, nuclear industry or even for cosmetics. It can meet FDA, GMP or ANIA standards and criteria. With the robustness and strength of hammer crusher

Request for a quoteResults for

Pin mills - Import exportNumber of results

8 ProductsCountries

Company type