- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pellet line

Results for

Pellet line - Import export

COMERC SP. Z O.O.

Poland

We design, manufacture, build, train and service The pellet production lines designed and installed by our company offer capacities ranging from 2 t/h to 20 t/h. The capacity achieved naturally depends on the number and power of the machines and equipment comprising the production line. Pellet production lines – the offer: •design (technical conceptual design, formal arrangements, technical documentation, manuals, cost calculation), •supply (machines, devices, measuring and control apparatus, control cabinets, and all installation materials), •installation (machines, devices, control cabinets, measurement, control and feed wiring, post-installation testing, acceptance measurements), •software (controllers, operator panels, visualisation and control systems), •commissioning (machines, devices, control cabinets, control and power installations), •training process operators, programmers and IT technicians and technical human resources, •service within the warranty period and beyon

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We also have our own production program, which covers the areas of telecommunications, railways, post office and dedicated industries. We have also developed a pellet production line.

Request for a quote

DURO DAKOVIC STROJNA OBRADA D.O.O.

Croatia

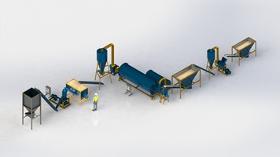

Our company has been producing a pelleting line for pellet production from biomass. Pellet mill capacity and complete lines is 500 kg/h of wood pellets and 1000 kg/h of Biomass. Pallet lines are suitable for sawmills, furniture manufacturers, farms and others. Below you will find the layout of pellet lines, which are designed according to specific customer requirements depending on their production areas

Request for a quote

J.D.F. IMPORT-EXPORT GMBH

Germany

Product name Original Premium Wood Pellet line EN Plus-A1 Wood Pellet Packed Material Hard wood Moisture ≤ 10% Calorific Content 4000 - 4900 Kcal/Kg Density 600-800Kgs/CBM Length 30 - 50mm Diameter 6 - 8mm Packing 15kg Plastic Bag Usage Cooking Fuel - Heating System BRAND As Customer Requirements

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source. Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust. Advantages Processing of wet chips (moisture u > 100%) Flake preparation of chips to a coarse saw dust type material Ensure the fibre supply in existing processing lines High machine availability at lowest maintenance an labour costs Independence from saw dust supply Future-proof for the usage of different material types by simple adjustment of...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

Chaoyang runxing heavy machinery Manufacturing Co.,ltd are engaging on manufacturing heavy machinery equipment and spare parts for almost 40 years, we could provide cement production line, rotary kiln, cement mill, ball mill, raw mill, slag mill, cement grinding equipment, preheating equipment, laterite nickel rotary kiln, oxidized pellet production line, air swept coal mill, mining mill, autogenous mill, semi-autogenous mill, rolling machine, vertical mill, crushing equipment, cooling machine, drying equipment, fluidized bed furnace, compound fertilizer equipment, blending machine, feeding machine. We passed the certification of ISO9000. Please contact us for more details. zoeyguo369@gmail.com wechat:chaoyangrunxing

Request for a quote

UTF

Ukraine

Capacity: 250-2000 kg/h Thickness of product: 0,9-1,1 mm Raw materials: flour, semolina Energy source: liquid fuel, solid fuel, electricity, gas Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - apart of short cut pasta it is possible to produce potato pellets on the same line - automatic batching system of raw materials is foreseen - machinery provides homogeneity of mixing of components - high quality of the product due to mixing and pressing is made in vacuum conditions - press is completely automatic - flexible system for the adjustment of product dimensions is foreseen - humidity and temperature in the dryer are maintained automatically - different recipe can be use - design of lines can be developed according to customer’s production premises Equipment set of the line: - bag tilting device - flour sifter-batcher - press - trabatto - elevator - drying chamber - cooling chamber - elevator - storage hoppers

Request for a quote

SEQUOIA HOLZ GMBH

Germany

We are certified Manufacturer of wood pellets according to the ENplus® A1 Standard. When buying chopped Wood pellets & firewood, you get high-quality and eco-friendly products, which provide high heating emission (due to drying of moisture of 8-12%), do not smoke, do not pollute the environment and prolong the service life of heating plants. Diameter: 6 mm Energy content: about 4,9 кВтг/кг Moisture: 8-10% Ash content: ≤ 0,7% Raw material: 100% wood Gross CV (d): 4977 kcal/kg Certificates: ENplus A1 The price for chopped firewood and pellets which meet the quality standards is based on the cost for fuel production without hidden charges. Cost-effective delivery to partners Delivery in Germany and anywhere in Europe is carried out by our partners — carrier companies, which offer several delivery options Certified production The fuel pellets production lines are equipped with modern domestic systems, certified by European standard

Request for a quoteResults for

Pellet line - Import exportNumber of results

9 ProductsCompany type