- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- parts-counters

Results for

Parts-counters - Import export

SCHMITTER HYDRAULIK GMBH

Germany

Sechskantmuttern Category Screw connections, adapter a. accessories / Pipe connections 24° DIN 2353 / Parts / Counter nuts / Steel Product number supplier 300706

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Screw connections, adapter a. accessories / Pipe connections 24° DIN 2353 / Parts / Counter nuts / Steel Product number supplier 321263

Request for a quote

METAL TECHNOLOGY GROUP

Bulgaria

Machine low pressure die-casting of aluminium parts, counter pressure die-casting and high pressure die-casting with crystallization (“liquid, semi-liquid” stamping) of AlSi based alloys in accordance with EN 1706 6

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Robustness, accuracy, and simplicity are attributes characterizing this ultrasonic welding machine. The entry-level models already include a position measuring system and proportional valve technology as basic equipment. Moreover, password protection and part counter are standard. Precision guiding rails and reliable drive components ensure repeatable welds.

Request for a quote

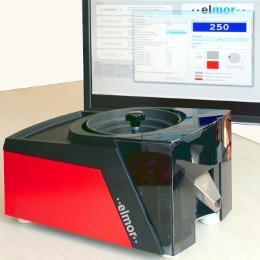

ELMOR

Switzerland

The PC controlled, high sensitive elmor C3 Seed counter is preferably used in scientific counting tasks in laboratories Universities, research and breeding projects or in seed quality control etc. Parts that can be processed with the C3 seed counter are, for example: Dust fine plant seeds such as Arabidopsis thaliana or Begonia semperflorens Vegetable seeds, grains or seeds of ornamental plants Insects, pupae and eggs Small mechanical parts Pharmaceuticals Semiconductor chips etc. The C3 Counter is controlled solely via PC. Thus new solutions for the ever growing demands of the customers are possible. All settings and the results of all operations are logged and saved . This is an essential prerequisite for quality control and traceability of test results. The parts that can be counted with the C3 seed counter can be extremely small and irregularly shaped. Thus they are very difficult to handle manually. Dosing these parts with scales is often flawed or impossible. Therefore the use of the of C3 opens new options, since e.g. smallest parts in the sub-milligram range can be dosed faster and more accurately by counting than weighing the pieces. With additional software modules also further evaluations can be performed. These are currently: direct 1000 grain weight determination and the grain size analysis. Technical data Counts Parts from 0.1 to 18mm in diameter For spheres of 2mm diameter: Counting rate: 50’000 parts per hour Typical counting error: less than 1/1000 Runs under Windows XP/7/8.1 Free Serial Port (RS232) or USB needed Software included Totalizer Preset Counter Additional software available: Direct determination of the 1000 Kernel Weight Analysis of the size of the counted particles: Particle Size Analysis Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Automatic 1000 Grain Weight Measurement By means of an additional software module, an electronic balance and a special frame, the precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 500 or 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without no arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. But most important is that in this procedure the particle size selection is impossible. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Particle Size Analyzer The precision seed counter C3 can be used as particle size analyzer to determine the particle size distribution of a given sample by means of a special software module. The size of the singularised and free falling parts is measured in one dimension with a resolution of some 1/100 mm. This measurement is intended primarily to compare different samples qualitatively. With spherical parts the measurements give also quantitative information. The measured values of the particle size analyzer are stored as txt file. This makes it possible to further process the raw data individually by means of appropriate standard software. Filling Carousel The C3 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of our counting machines C1, C3 or CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity Click here to add your own text Click here to add your own text

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELMOR

Switzerland

Seed counter, counter for small parts elmor C1 The elmor C1 is a universal counting machine for any small and irregularly shaped parts, such as: Finest plant seeds Vegetable seeds Cereals, Maize, Rice, Canola Insects, Pupae, Eggs Pharmaceuticals, pills, casules Gems, diamonds and precious stones Bulk semiconductor chips Small mechanical parts Implants All these products have in common is that they are either irregularly shaped, lightweigt or very small. Therefore these parts are difficult to handle manually. Dosing these parts with scales is often flawed or impossible. The seed counter C1 is specialized for exactly counting of such parts in small to medium quantities. Important applications of the C1 seed counter are the repetitive, precise counting of a preselected number of parts or the conventional determination of the 1000 grain weight according to ISO 520:2010. Parts with diameters from 0.2mm to about 18mm can all be processed with the same adjustable conveyor bowl. For fast counting of large amounts the 650 multi-channel counting machine can be used. The seed counter C1 is characterized by a robust construction, a fool-proof operation and a large, bright display that is easy to read even in daylight. The count signal is processed by a microprocessor which allows also the detection of parts with particularly difficult shapes. The parts counter C1 is equipped with terminals for remote control so that it can be combined, for example with packaging and filling machines. The C1 seed counter is the successor of our model 600, which was produced from 1980 for about 25 years. The new seed counter elmor C1 combines modern electronics with the proven key components that were already responsible in the previous model for long durability and unmatched accuracy. The C1 can be described with attributes such as longevity, durability, robustness and reliability – this for many years. Technical data Counter for small parts from 0.2 to 18 mm in diameter (*) Cylindrical parts can have a length of up to 20 mm (*) Only one adjustable conveyor bowl is used for the whole size range Conveyor bowl: anodised Aluminium, sorting element FS-0. Other bowls and sorting elements available on request Display and preset range of the counter: 0 to 99’999 Modes of operation: Preset counter, Totaliser The conveyor speed is reduced shortly before reaching the desired quantity to achieve a high dosing accuracy External connections allow the combination of the seed counter C1 with other devices, e.g. packaging machines. Typical performance data for spherical parts of 2mm diameter: Counting speed: about 50’000 parts per hour Counting error: 1/10’000 for clean, easy to separate parts Modes of operation: Totaliser Preset counter (*) other sizes on request The C1 counting machine is the central part of a system that can be adapted for many different applications. Some variants are standardized available, such as: Conveyor bowls for specific tasks Counter with dual product outlet Automatic seed weight sorter Filling carousel for bags and/or vials Filling adapter for containers Dust cover Ionizer Receipt printer Feeder / hopper with a few litres storage volume If your application can not be covered with these accessories, please contact us so that we can propose you a customized solution. elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Non-closable venting panel that with a pressing break opens itself letting the area completely free. The opening takes place thanks to the carvings breakage and relative “extraction” of the panel from its gasket. The plastic hinge guarantees that the panel remains opened without any projection of panel or counter-frame parts. This type of safety device is intended for protection from possible explosions, caused by a sudden pressure increase of equipments containing air/dust mixtures or gas/air potentially explosive mixtures such as silos, separator filters, bucket elevators, sieves, mixers, tanks, canals and pipelines, dust collectors, dryers, etc. All panels are breaking and safety devices and have been certified in accordance with UNI EN 14797: 2007. Opening efficiency: Ratio between the relief and the total area. Relief area: Area of the supposed venting device which is free from inertia. It shows the same effects of pressure reduction of the real device. Kst...

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Non-closable venting panel that with a pressing break opens itself letting the area completely free. The opening takes place thanks to the carvings breakage and relative “extraction” of the panel from its gasket. The plastic hinge guarantees that the panel remains opened without any projection of panel or counter-frame parts. This type of safety device is intended for protection from possible explosions, caused by a sudden pressure increase of equipments containing air/dust mixtures or gas/air potentially explosive mixtures such as silos, separator filters, bucket elevators, sieves, mixers, tanks, canals and pipelines, dust collectors, dryers, etc. All panels are breaking and safety devices and have been certified in accordance with UNI EN 14797: 2007. Opening efficiency: Ratio between the relief and the total area. Relief area: Area of the supposed venting device which is free from inertia. It shows the same effects of pressure reduction of the real device. Kst...

Request for a quoteResults for

Parts-counters - Import exportNumber of results

9 ProductsCountries

Company type

Category