- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- part works

Results for

Part works - Import export

BULUT CNC MACHINING

Turkey

Experience unparalleled precision with BULUT CNC MAKINA's bespoke CNC projects, meticulously crafted in Turkey. Committed to excellence, we specialize in tailoring components to match your unique requirements. From intricate machinery parts to bespoke project elements, our team employs cutting-edge CNC milling, turning, and machining techniques for optimal solutions.We redefine excellence in the realm of brass machined parts manufacturing. With a relentless commitment to quality, innovation, and customer satisfaction, we stand as the premier destination for businesses seeking top-tier brass components for their diverse applications.

Request for a quote

DOGA MAKINA

Turkey

Production with Material (Manufacturing) : Our company provides the material needed for the manufacturing of the requested part. After engraving and doing quality control in accordance with the technical drawing measurements, our company ships the buying company the product with final reports. ⦁ Production without Material (Engraving) : Buying company provides the material themselves and sends it to our company. This could be casting or any type of material. Materials that arrive to our company are first controlled in terms of their measurements. When they are approved, our company prepares a manufacturing plan/program and starts working on specimens. Part with taken specimens are delivered to the buying company. With the approval of the buying company, manufacturing begins, and after doing its quality control it is delivered to the buying company with its final measurement reports.

Request for a quote

MALAIKA TEXTILE AGENCY IMPORT EXPORT

Turkey

Our work jackets collection, with its durable materials and stylish designs, offers a professional look in every work environment. Lightweight and comfortable, yet packed with functional features, our work jackets will become an indispensable part of your daily work routine.

Request for a quote

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

Engine Sump part - Cnc milling & painting

Request for a quote

STEEC

France

Spark erosion involves removing material from a conducting part and eroding it to give it the desired shapes and dimensions by means of electrical discharges. In the wire sparks erosion process an unwinding metal wire, under tension, is immersed in water or in another insulating liquid (dielectric) with the part to be worked. The current transmitted forms an electric arc which gives rise to precise, programmed degradation of a section of the part. The residues created by wearing of the part are removed by the water or dielectric liquid. STEEC carries out both spark erosion and fine wire micro spark erosion operations Wires spark erosion and machining Equipped with the latest wire spark erosion technologies, STEEC is able to carry high precision cutting with wires of standard sizes whose diameter may vary from 0.15 to 0.25 mm in all types of mechanical parts.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK workpieces are the ultimate solution for those seeking unrivaled durability and reliability in their manufacturing processes. These advanced materials offer exceptional mechanical properties, including high tensile strength, excellent creep resistance, and low coefficient of friction. PEEK workpieces are also known for their dimensional stability, resistance to chemicals, and high temperatures, making them ideal for demanding applications. With their versatility and performance combined, PEEK workpieces are setting a new standard in the industry, offering enhanced efficiency and productivity to manufacturers worldwide.

Request for a quote

CMPLAST

Poland

Occurs in three basic versions PE 300, PE 500, PE 1000. Due to its many advantages, polyethylene has found a wide application in today's modern machine industry. Its very good cutting properties make it a series of various machine parts that work primarily in the bottling, food, chemical, cosmetics and automotive industries.

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With our modern CNC boring machines, CNC milling machines and CNC lathes we work on steel construction components and process forgings and castings into precision components for mechanical engineering. Our cutting machine operators work precise on parts that are up to 10 meter long and weigh 25 t - with an accuracy of 0.01 millimeters. This is how customized mechanical engineering elements are created, such as: - wind power components - press stand - gear housing for mining ... The machining technicians create the individual CNC programs together with our CAD specialists directly on the CNC machines. An integrated management system and the uniform control concept from Heidenhain guarantee a high degree of flexibility; all CNC machines for heavy-duty machining are networked and access a central data pool. This is how we guarantee you fast programming and set-up times, absolute repeatability and adherence to schedules.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Below are a few reference objects that we have been able to work on as part of a wide variety of project tasks in recent years: Audi: all RS models since 2000, R8, R8 2015 Bentley: Mulsanne, Bentayga BMW/Mini: Clubman, 3 series Ferrari: 599 GTO Lamborghini: Gallardo, Murcielago, Aventador Mercedes: S-Class, SLS, Actros Porsche: 997, 911 I panel, door trim, center console, greenhouse, interior trim, trim, steering wheel, seats, carpet trim, infotainment system, instrument cluster, mirror, selector lever, switch panel, trunk, engine compartment cover. Wheels, brakes, wheel suspension, exhaust system, engine components, tank, lines. Plastic injection moulding, metal casting, forging, forming, tube processing, painting, galvanic surfaces, lamination, leather covering, upholstery and sewing.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Laser cutting parts and bending parts: Your special production in good hands. As part of the Schulz Group, Schulz Stanztechnik can also offer you – as a service and in addition to the stamping program – special laser cut parts in various materials and thicknesses. In accordance with your drawings, you will receive a meaningful offer from us within three working days, and your laser parts within ten working days of your order. Manufacture of 2D and 3D laser parts made of the most diverse of materials as well as angles in accordance with your drawings and specifications.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Hai Tong is one of the leading manufacturer of high-volume, precision metal stampings for OEMs in the medical, automotive and electronics industries. Our skilled workers using in high speed metal stamping process to produces complex stamping parts which are of the highest quality standard and one stop solution for your specific parts. High speed precision stamping is the most cost-effective solution to produce small, tight tolerance but large volume parts, we can work with a variety of materials, such as copper alloys, stainless steel and carbon steels, and spring steel, enriched with years of experience in fabricating electronics metal stamping parts and medical stamping parts leads us to be top manufacturer who have enough knowledge to make the most complex stamping parts with stable quality and on time delivery. When components are produced through high speed stamping, the assembly process is also greatly simplified.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The GESIPA® TRI-FOLD® blind rivet forms three press lashes on the closing head side during setting. The advantages The large moulded lashes distribute the exerted clamping force evenly and gently onto the riveted material. Also, the large surface of the lashes offer excellent protection against the rivet being pulled through very soft, porous or brittle application parts. Thanks to its special design, the TRI-FOLD® is also able to compensate over-dimensional or irregular drill hole diameters. Application areas TRI-FOLD® blind rivets are excellently suited for the automotive field, e.g. for plastic panelling, car body parts and for the interior work inside vehicles, but also for all other applications that are particularly soft, brittle, easily deformed or porous.

Request for a quote

GRAVOTECH

France

COMPACT DOT PEEN MARKER With 3 sizes available our compact size is the smallest identification marking on the market. This makes the XF150p ideal for restricted spaces and whether on the line or on a robotic arm. The integration is simple in any position, reducing the time and cost of installation. FAST DOT PEEN MARKING When short cycle times are a must, the XF510p dot peen marker is for you, with a marking speed of 12 characters in one second possible, it is setting new standards for speed. TIRELESS PARTS MARKING Able to work on uninterrupted production lines, the XF510p was designed to last. Made with high quality parts we have thousands of units used for aluminum plate engraving, steel engraving, and steel plate engraving worldwide, providing maximum reliability and minimum maintenance costs.

Request for a quote

ZEYTAS CELIK MAKINA SAN. VE TIC. A.S.

Turkey

We processed 1000 tons of steel for our project, which will cover an area of 16.800m². We prepared the parts of our work, in which each stage was developed in detail and meticulously, for assembly, and transferred them from Turkey to Northern Iraq without any problems.

Request for a quote

ASBER GMBH

Germany

“A solid wooden table is a part of a flawless work of nature, every texture tells a story and is a manifesto of nature's inspiration; “This table is an immortal reminder of the life of the tree.” In order to be able to present the topic of trees in its purest form, we develop ideas and projects. We work with university art faculties and enable our products to come from the hands of artists. Above all, we are proud to support art students as part of a social project. Solid trunk/wood coffee table has been carefully selected and crafted from a single solid piece of natural wood that is 400-500 years old. Therefore, it should not be compared with composite tables. No chemicals were used in the manufacturing process and it was entirely handmade. This special table, of which only one was made, serves to bring functionality to nature's art.

Request for a quote

ASBER GMBH

Germany

“A solid wood coffee table is part of nature's perfect work, every texture tells a story and is a manifesto of nature's inspiration; “This table is an immortal reminder of the life of the tree.” We develop ideas and projects to present the topic of wood to you in its simplest form. We work with university fine arts departments to ensure our products come from artists. Most importantly, as part of a social project, we look forward to supporting art students. The natural wood coffee table is made from carefully selected solid pieces of natural walnut wood that is 400-500 years old. Therefore it should not be compared with assembled tables. No chemical substances were used in the production process and it was entirely handmade. This special table, of which only one was made, serves to add functionality to nature's art.

Request for a quote

ASBER GMBH

Germany

“A solid wood coffee table is part of nature's perfect work, every texture tells a story and is a manifesto of nature's inspiration; “This table is an immortal reminder of the life of the tree.” In order to present the essence of wood in its simplest form, we develop ideas and projects. We work with university art schools to ensure that our products come from the hands of artists. Most importantly, we are proud to support art students as part of a social project. The Natural Wood Coffee Table, Solid Wood Coffee Table, is made entirely of carefully selected solid pieces of natural walnut wood that is 400-500 years old. Therefore it should not be compared with assembled tables. No chemicals are used in the production process and it is entirely a result of craftsmanship. This special table, only one of which is made, adds functionality to nature's art.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

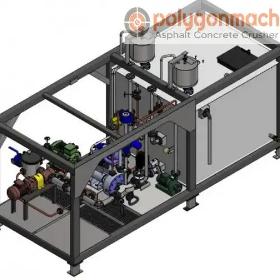

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 300-ton horizontal bitumen tank is a gigantic, specially designed storage unit for handing bitumen, that thick, sticky substance processed from crude oil. These large-capacity storage units have been designed to hold huge quantities of bitumen and, therefore, turn out to be quite practical for industries needing this material in bulk. These horizontal tanks can handle, heat, and store bitumen with greater ease. They thus form a very essential part of works that need a stable supply of bitumen. Made of strong steel, these tanks are designed to weather the demands of handling bitumen: high viscosity and requirements for heating at high temperatures. A 300-ton horizontal bitumen tank can provide reliable and hardened storage that guarantees the bitumen will stay in a workable state, ready either for transportation or immediate use in many industrial applications.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Destroy bacteria, inhibit algae growth and reduce scaling in wastewater. PRAB’s line of ozone generators are used for all types of industrial water applications. From recirculated washwater to bacteria control in water-based metal working lubricants and parts rinsing operations. Water treated with ozone does not contain any chlorinated compounds that require further treatment prior to disposal. Ozone is known as the most powerful commercial oxidant in the world, because it is highly reactive and readily oxidizes (breaks down) organic matter. Ozone is used to treat process and wastewater in a sterilization system. It has a faster reaction rate than chemicals and is used as a disinfectant for drinking water, as well as a disinfectant for destroying bacteria, inhibitor to algae growth and scaling reducer in wastewater.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

SCHMIDT Zerspanungstechnik will meet even the most demanding customer requirements SCHMIDT Zerspanungstechnik sets high standards in terms of precision and quality when it comes to turning too: Our modern machinery includes various CNC lathes that boast the latest technology. The features of our high-precision machinery allows us as a machining specialist for large parts to produce work pieces with a swing of up to 1,100 mm and turning lengths of up to 4,500 mm and achieve the required surface finish with ease. Our lathes have roller burnishing and grinding tools so that your work pieces and semi-finished products can be individually customised to your specifications and special finishes realised. As a machining specialist for large parts, we rely on top quality and reliable processes when it comes to turning too.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

SCHMIDT Zerspanungstechnik is the partner of choice for demanding welding solutions SCHMIDT Zerspanungstechnik's modern machinery offers a variety of welding options for the manufacture and working of components and large machine parts. As a dependable specialist in the processing of large parts, we can weld work pieces with a unit weight of up to five tons and flexibly adjust to accommodate different needs, including heat treatment and documented testing procedures: Our qualified and experienced staff are at home with various different welding techniques, such as MIG/MAG, TIG and arc welding. On request, we can carry out hardfacing of work pieces and large parts and employ special welding methods as part of the contract manufacturing service. Do you have any special wishes or requirements? We also weld custom solutions and highly complex parts with the utmost precision - on time and for a reasonable price. Our welding workshop is certified according to DIN EN ISO 3834.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With Polygonmachs PBA 100-120 TPH Stationary Asphalt Plant Explore the Future of Efficient Asphalt Production The Polygonmach PBA 100-120 TPH Stationary Asphalt Plant has the power to completely change how asphalt is produced for large-scale building initiatives. This state-of-the-art equipment is an essential part of large-scale construction projects because it is made to maximize and streamline asphalt production. This post covers the intricate internal workings parts assembly process and special features that distinguish the PBA 100-120 TPH Stationary Asphalt Plants from rivals in great detail. What goes into building a PBA 100-120 TPH Stationary Asphalt Plant? Large-scale construction projects require an asphalt production plant with a high capacity and the PBA 100-120 TPH Stationary Asphalt Plant is designed to meet those needs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Polygonmach PBA 40-60 Tph Stationary Asphalt Plant is your gateway to productive asphalt production. The PBA 40–60 Tph Stationary Asphalt Plant by Polygonmach is a state-of-the-art option made to maximize the production of asphalt for a variety of building projects. This cutting-edge machinery guarantees reliable and effective performance making it an invaluable resource for any major construction project. This post will explore the PBA 40–60 Tph Stationary Asphalt Plant including its definition workings major parts assembly procedure and unique selling points. What is the 40–60 Tph Stationary Asphalt Plant manufactured by PBA? The PBA 40–60 Tph Stationary Asphalt Plant is a stationary high-capacity facility designed to generate premium asphalt. This plant is made to handle the demands of large-scale construction projects because it can produce 40 to 60 tons of asphalt per hour.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Polygonmach PBA 40-60 Tph Stationary Asphalt Plant is your gateway to productive asphalt production. The PBA 40–60 Tph Stationary Asphalt Plant by Polygonmach is a state-of-the-art option made to maximize the production of asphalt for a variety of building projects. This cutting-edge machinery guarantees reliable and effective performance making it an invaluable resource for any major construction project. This post will explore the PBA 40–60 Tph Stationary Asphalt Plant including its definition workings major parts assembly procedure and unique selling points. What is the 40–60 Tph Stationary Asphalt Plant manufactured by PBA? The PBA 40–60 Tph Stationary Asphalt Plant is a stationary high-capacity facility designed to generate premium asphalt. This plant is made to handle the demands of large-scale construction projects because it can produce 40 to 60 tons of asphalt per hour.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik will meet even the most demanding customer requirements SCHMIDT Zerspanungstechnik sets high standards in terms of precision and quality when it comes to turning too: Our modern machinery includes various CNC lathes that boast the latest technology. The features of our high-precision machinery allows us as a machining specialist for large parts to produce work pieces with a swing of up to 1,100 mm and turning lengths of up to 4,500 mm and achieve the required surface finish with ease. Our lathes have roller burnishing and grinding tools so that your work pieces and semi-finished products can be individually customised to your specifications and special finishes realised. As a machining specialist for large parts, we rely on top quality and reliable processes when it comes to turning too.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik is the partner of choice for demanding welding solutions SCHMIDT Zerspanungstechnik's modern machinery offers a variety of welding options for the manufacture and working of components and large machine parts. As a dependable specialist in the processing of large parts, we can weld work pieces with a unit weight of up to five tons and flexibly adjust to accommodate different needs, including heat treatment and documented testing procedures: Our qualified and experienced staff are at home with various different welding techniques, such as MIG/MAG, TIG and arc welding. On request, we can carry out hardfacing of work pieces and large parts and employ special welding methods as part of the contract manufacturing service. Do you have any special wishes or requirements? We also weld custom solutions and highly complex parts with the utmost precision - on time and for a reasonable price. Our welding workshop is certified according to DIN EN ISO 3834.

Request for a quote

TIRAS TECHNOLOGY

Ukraine

DETECTO SMK100 detects fire at the first appearance of smoke. Works as part of the Tiras PRIME A system.

Request for a quote

TIRAS TECHNOLOGY

Ukraine

DETECTO SMK110 notices fire at the first appearance of smoke. Works as part of the Tiras PRIME A system.

Request for a quote

TIRAS TECHNOLOGY

Ukraine

DETECTO MNL100 is an addressable manual call point designed to work as part of the Tiras PRIME A system. It is installed in the protected premises for generation a fire alarm signal in manual mode.

Request for a quoteResults for

Part works - Import exportNumber of results

108 ProductsCountries

Company type

Category

- Alarms - security devices (7)

- Milling - steels and metals (5)

- Concrete preparing - machinery and equipment (3)

- Couplings, mechanical (3)

- Injection moulding of rubber and plastic (3)

- Marking machines (3)

- Veneers (3)

- Wood and furnishing - treatment and protection (3)

- Greasing equipment (2)

- Industrial washing facilities (2)

- Machine tools, cutting - parts and accessories (2)

- Plastic products for engineering (2)

- Sawmills - machinery and equipment (2)

- Automation - systems and equipment (1)

- Bicycles, accessories and parts (1)

- Bitumens (1)

- Body-building - equipment (1)

- Brass (1)

- Cleaning, tanks and cisterns (1)

- Components and parts for large household appliances (1)