- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pallet changer

Results for

Pallet changer - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

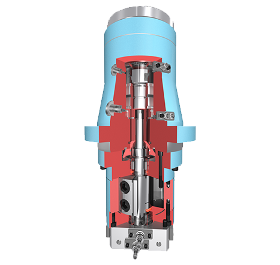

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

TOPPY S.R.L

Italy

This mobile pallet turner is an electrically powered trolley with a maximum capacity of 1500 kg, operated by tiller controls and powered by a gel battery. It is an extremely versatile and compact device that allows the replacement of the pallet to be carried out in very confined spaces, thus not requiring an area to be dedicated in the plant. Falcon Wing is also available as a stationary machine. The mobile bench vault is equipped with the latest generation gel batteries with a duration of 8-10 hours. It is possible to increase the duration with larger batteries. In addition, to ensure that mobile devices have a non-stop operating cycle, we provide the optional “roll-on / roll-off”, a quick battery change system. All Toppy equipment are equipped with safety systems in order to prevent accidents at work, with particular attention to GMP standards to ensure the appropriate quality standards.

Request for a quote

EASY-TEC SARL

France

Retourner des charges de 180° Précision et sécurité Système compact ne nécessitant pas de barrière de protection Chargement possible par gerbeur Accessibilité 4 côtés Applications nombreuses : - changement de palette - transfert de colis - maintenance de moules, de gros outillages - basculement de bobines - retournement de paquet de dôle, plaques de plâtres, plaques de bois ou autre

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

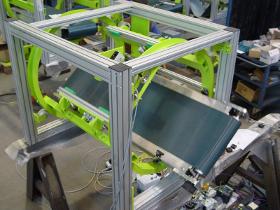

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FUSED MACHINERY

Belgium

This CO2 laser cutting machine is in excellent condition and it is equipped With: Mitsubishi M700 Control Mitsubishi 45CF-R Resonator (4.5 kw) Non-Contact Cutting Head 5" & 7" Lenses Automatic Heavy-Duty Pallet Changer Chiller Unit Dust Collector Includes Spare Parts & Consumables Bar Code Reader Device with Software The machine has been serviced by Mitsubishi only and has a full service history of every part that has been changed over the years. Everything was changed in time.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quoteResults for

Pallet changer - Import exportNumber of results

8 ProductsCountries

Company type