- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging machines for bags

Results for

Packaging machines for bags - Import export

CUPASO DEUTSCHLAND GMBH

Germany

Standard elements : - Robust frame in grey or white lacquered steel - Conformator tube - Welding jaw with heating rod (hard chrome plated) with constant temperature controlled by temperature controllers with digital display - Drive of the film by belt - Motorisation of the unwinding of the roll - Control generated by SPS - Touch screen display - Programme memory (weight, length of bags...) - Fine detection of the reel - Translucent mapping Material according to current EC standards. Films that can be used: polypropylene, composite, aluminium, barrier, polyethylene.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 55 was developed to meet the demand for high throughput rates. Flexibility, easy maintenance, simple settings, synchronisation with the infeed systems, flexibility and quiet operation were the priorities in the development of this machine. The machine achieves an output of up to 80 bags / minute. The most common options and accessories: - Hanger hole - Precutter for easy opening - Jogger to level the products before closing the bag - Bag identification system: - Marking by transfer to the film - Label printer - Inkjet printer - Flap for heavy products - Cell for pre-printed film - Drive by suction belts - Synchronisation with: - Multihead weigher - Auger filler - Cup doser - All other machines - Suction plate for changing the film roll

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 06 form fill and seal machine uses standard polyethylene, biodegradable oxo sleeves or biodegradable sleeves (starch-based). The TEC 06 is particularly suitable for the production of display bags. The sealing head simultaneously performs the top seal of the pouch and the bottom seal of the next pouch, a cut is made between the two welds, and at the same time a pre-cut is made across one thickness of the sleeve to form a "kangaroo pocket" that allows the pouch to be filled. As this pocket is firmly connected to the spool, slippage is not possible, so that the weld seams subsequently run perfectly parallel. Due to the functionality and quality of its equipment, the TEC 06 is a very reliable machine that consumes few wearing parts.

Request for a quote

FERPLAST SNC

Italy

The cushioning machine AIR BAG FP 600 G is compact and silent and allows you to create air cushions for packaging. It is suitable for use in the food, pharmaceutical, farm and wine industries and wherever it is necessary to pack fragile products such as glass jars, bottles and fragile products.

Request for a quote

FERPLAST SNC

Italy

SEALING MACHINE/BAGGING MACHINE MOD. SUPER - FOR MASSIVE PRODUCTS Machine consists of a loading tube on which a tubular film with a width of 50 cm is fitted. and a manually operated sealing bar. The loading tube is slightly inclined and facilitates the sliding of the product inside the film, without causing sudden falls. By lowering the sealing bar a perfectly sealed bag is obtained and at the same time the bottom of the next bag is created, a hot cutting system separates the two packages. The SUPER bagging machine can be positioned at the entrance barriers of hypermarkets, supermarkets, shopping centers, to reduce theft, small objects but it is also widely used for packaging technical items, clothing, linen, etc.

Request for a quote

STATEC BINDER GMBH

Austria

The SYSTEM-F, a fully automatic vertical form-fill-seal packaging machine, produces pillow bags and gusset bags with or without carrying handle and a filling weight between 5 kg and 50 kg from flat film. The System-F is particularly ideal for packaging powdery and moderately free-flowing products. Thanks to an adjustable format set, different package sizes can be produced. The format and/or production can be changed by one person in just a few minutes. This is made possible by a rotating magazine, which is installed directly on the machine and holds several format sets of different sizes ready at all times. The vertical FFS packaging machine impresses with its compact design and low space requirement. Further options allow this bagging machine to be adapted to a wide range of requirements.

Request for a quote

STATEC BINDER GMBH

Austria

The CERTOPAC, a fully automatic high-performance bagging machine, packs any type of free-flowing bulk material in pillow bags and gusset bags with a filling weight between 5 kg and 80 kg. Thanks to its high speed, this open-mouth bagging machine can fill up to 1500 bags per hour. Because of the high flexibility of the packaging machine, bags made of woven PP, PE and paper can be processed. Furthermore, the CERTOPAC stands out due to its easy accessibility and high reliability. This high-performance packaging machine is also available as CERTOPAC-S and CERTOPAC-L in addition to the “standard version”. The differences between the variants are the bag magazines (rotating bag magazine or push magazine), the different filling weights and sizes of the bags. Furthermore, the CERTOPAC can also be completely made of stainless steel and equipped for powdery products.

Request for a quote

STATEC BINDER GMBH

Austria

The PRINCIPAC is a fully automatic high-performance bagging machine for open-mouth bags and, with up to 2000 bags per hour, it is one of the fastest in the world. The PRINCIPAC is characterized by high performance and flexibility. Both pillow bags and gusset bags with a filling weight of 10 kg to 50 kg can be processed. The bags can be made of woven PP, PE and paper. This fully automatic open-mouth packaging machine is ideally suited for any type of free-flowing bulk material and with additional equipment such as a dustproof filling spout also for powdery products. Depending on customer requirements, the high-performance bagging machine can also be made entirely of stainless steel. Further options enable the PRINCIPAC to be optimally adapted to customer requirements.

Request for a quote

STATEC BINDER GMBH

Austria

The ACROPAC is a fully automatic bagging machine with a production capacity of up to 600 bags per hour. Hence, this open-mouth bagging machine is ideal for those who want to change from manual/semi-automatic packaging to fully automatic packaging and/or require low capacity. Whether plastic pellets, animal feed, fertilizer or food, the ACROPAC is ideal for packaging free-flowing bulk materials. Due to the high flexibility of the machines, pillow bags and gusset bags with a filling weight between 10 kg and 50 kg can be filled. The bags can be made of woven PP, PE or paper. In order to meet special requirements, the machine is also available in a stainless steel execution and can be equipped for powdery products.

Request for a quote

BISS

Poland

We offer a film for packaging various fresh fruit, including apples, pears and citrus fruits, in the form of LDPE and BOPP tapes, and BOPP/LDPE laminates for automatic flow pack packaging machines. We also have ready-made bags to be used in agriculture and food industry, and in horticulture.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Materials: stainless steel, carbon steel, alloy steel, aluminum, zinc alloy, copper, brass,POM, PC, PA, Teflon, PVC and ABS Process: raw material, rough machining, finish machining Surface treatment: plating, spraying, anodizing, electro polishing and coating Tolerance: ±0.01mm OEM/ODM orders are welcome Customized designs are welcome Standards: DIN, JIS, ASTM, AISI, BS and GB Packaging: precision machining parts Inner: PE bag or customized Outer: wooden case or carton or customized Size: customized

Request for a quote

GAICTECH

Spain

The Bagging Machine for Tuna Loins is designed for the semi-automatic insertion of cooked and clean tuna loins into bags, streamlining the preparation process for subsequent freezing. Capable of handling 7 kg bags at a rate of up to 8 bags per minute and 10 kg bags at up to 6 bags per minute, this machine requires 4-5 operators for optimal performance. Constructed from durable and hygienic stainless steel AISI 316-304, it ensures longevity and compliance with food safety standards. The volumetric filling system guarantees great uniformity in the volume of bags filled, without producing pieces or flakes, enhancing product quality. Its design facilitates easy cleaning, as it can be fully disassembled, allowing all parts to be accessible. Additionally, the machine offers the flexibility to work with several bag sizes by simply modifying the length, accommodating various packaging needs. This bagging machine represents a significant efficiency

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

t is used to fill large-sized bags (big bag) used for transporting powdered and granular products

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with liquid pump cylinder measurement,accurate measurement, fast speed, low defective rate, low noise,add the reflow system can avoid liquid material leakage. 2. Eight stations rotary design to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5.Modular heating, more accurate temperature control, heating failure can alarm prompt. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

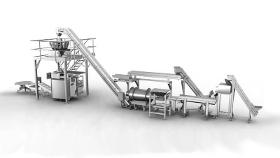

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Cheese chopping machine SCADA and HMI with a touch screen system Hardened stainless steel slicer and 3d chopping system Cups feeder system Antistick powder processing system Vertical conveyor transfer system Automatic suppress distribution system Electro pneumatic weighing cells 3 levels weighing cells Weighing tower Packaging machine Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Manual feeding system , automated feeding system is also available up to your request Drum blender with paddles and gravity positioning flow system Fast and automated powder storage release system . HMI, PLC with SCADA system integrated for easy workflow Tunnel conveyor transfer system for quick and easy powder transfer Automatic weighing tower Electropneumatic Automatic weighing cells Vertical powder packaging machine Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROEND HOTMELT

Turkey

t ProEnd Kimya, we ensure flawless bonding of carpet edges with our premium hotmelt adhesive products. HM 2701 is a high-quality hotmelt adhesive specially designed for joining carpet edges in the carpet industry. Key Features: EVA-Based: The EVA (Ethyl Vinyl Acetate) based formula provides exceptional bonding properties. Durability: HM 2701 offers long-lasting adhesion, ensuring that carpet edges are strongly and securely bonded. Easy Application: Its granular form in 25 kg bags allows for easy portability and application. Machine Compatibility: It can be seamlessly used with Carpet Edge Bonding machines. Packaging: Available in 25 kg bags. Machine Open and Drying Times: Can be adjusted according to customer requirements. Product Description: HM 2701 is developed specifically for joining carpet edges in the carpet industry. Its yellow color adds an attractive finishing touch to the edges. This high-quality hotmelt adhesive is an excellent choice

Request for a quote

ELMOR

Switzerland

The packaging machine elmor 800 is a small, compact and versatile packaging machine for premade bags like seed sachets. The machine can be combined with all elmor seed counters, but also with counting devices from other manufacturers or with other dosing devices such as dosing scales or volume-dosing machines. The seed counting and packaging machine elmor 800 can fill and close sealable flat bags or pregummed bags. In addition to the filling and closing, the bags can also be marked with an inkjet printer. Changing of the bags requires only a few seconds. A replaceable bag stack allows changing to other formats without time-consuming adjustments. Just change the stack and continue. Therefore, the packaging machine elmor 800 is especially suited for the packaging of seed specialties or organic seeds where many different varieties, but mostly small batch sizes have to be packed. The packaging machine elmor 800 is designed as a table top model.

Request for a quote

PROXIO CO.LTD

Russia

By reviewing information about your business, we understand that there are room for collaboration-expanding your range of packing machines. We would be glad to offer you cooperation on packaging-bagging machines. We manufacture a wide range of packaging machines. More than 10.000 of our packers of various uses and capacities are in use worldwide. As a confirmation of our quality, we state that we have automatic packers that been in daily use (3 shifts more than 10 years). Production program: Automatic packers for : Powder Granular Pelleted Liquid (bottles) Gel Cream Honey Cristal-sugar Piece ( automotive industry, biscuit) Pebbles and gravel Semi-automatic packers for: Powder Granular Pelleted Cream Liquid Card-board equipment: Scoring Slotting Gluing Punching Printing Make in a single pass the correct form of corrugated cardboard boxes.

Request for a quote

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag® AB 255™ automated packaging machine is capable of packaging at speeds up to 55 bags per minute. This large bag packaging machine can efficiently pack and seal polythene bags up to 400mm wide by 660mm long. Applications include large parts, kits and catalogues. Package size can be changed in less than two minutes using durable Autobag pre-opened bags-on-a-roll. System features include an advanced AutoTouch™ control screen for easy job set-up and recall, modular E-box and valve packs, and powered unwind for maximum cycle speed. This automatic packaging machine can be integrated with a variety of Autobag and third party infeed systems. The Autobag AB 255 automated packaging machine is manufactured for reliability and productivity and offers a cost-effective way to package various large products. ** Click for more **

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 220/50 Installed power, кW – 1,5 Pneumatic Supply, atm./l.m. – 150/4 Dimensions (not more than), mm – 2200/900/700 Weight ( not more than ), kg - 210 Packaging dimensions, mm – 20-150/17-50 Output (max), packs per hour - 12 000

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Power, Wt/Hz – 220/50 Installed capacity, кW – 1,5 Pneumatic Supply, atm./l.m. – 250/4 Dimensions (not more than), mm – 1800/900/1100 Weight ( not more than ), kg - 250 Packaging dimensions, mm – 50-150/50-150 Output (max), packs per hour - 2 000

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 380/50 Installed power, кW – 2,5 Pneumatic Supply, atm./ l.m.– 4/250 Dimensions (not more than), mm – 1600/1100/1200 Weight (not more than), kg - 320 Packaging dimensions, mm – 80-390/80-240 Output (max), packs per hour - 3 000

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 380/50 Installed power, кW – 2,5 Pneumatic Supply, atm./ l.m.– none Dimensions (not more than), mm – 1500/1100/1200 Weight (not more than), kg - 300 Packaging dimensions, mm – 80-290/80-190 Output (max), packs per hour - 2 700

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 220/50 Installed power, кW – 2 Pneumatic Supply, atm./ l.m.. – 250/4 Dimensions (not more than), mm – 1200/900/3500 Weight (not more than), kg - 450 Packaging dimensions, mm – 50-150/50-150 Output (max), packs per hour - 2 000

Request for a quote

AHTPM

Turkey

The G series packing machines work from reel to final bag. These machines are designed for forming, filling and sealing of doypack style pouches, 3 or 4 side sealed sachets, shaped pouches and pouches with spout. SPECIFICATIONS Full Servo Motion Control System 10’’ Hmi Lcd Touch Control Operating System Film Centering System Servo Controlled Scissors Servo Controlled Pouch Opening System With Vacuum Photocell Control System Heavy Duty Construction Servo Controlled Pouch Streching System No Open Bag No Fill System Zipper Aplication (Optional) Zipper Perforation And Opening System (Optional) Tear Notch System(Optional) Shaped Bag Molding System (Optional) Top Spout And Corner Spout Application System (Optional) Round Corner Application System (Optional) Euro Or Punch Hole Application System (Optional) Gas Flushing System (Optional) Inverter Controlled Roll Unwind System Printer Connection System (Optional) Stainless Steel M

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Tecnimodern's slanted or vertical form fill and seal machines with very low loading height allow the production of polyethylene or polypropylene film bags from a flat film roll. The film can be neutral or coloured, with continuous printing or centred with print mark. These TEC30 packaging machines have the advantage that they can be equipped with either a thermal sealing system for heat-sealed films or an impulse sealing system for polyethylene films, depending on requirements. To meet the need for all types of packaging, feeding and product shapes, we offer various automatic feeding systems, such as: - Counting with vibrating or centrifugal trays - Weighing with linear scales - Dosing by augers or volumetric feeders

Request for a quoteResults for

Packaging machines for bags - Import exportNumber of results

57 ProductsCountries

Category

- Packing and packaging - machinery and equipment (17)

- Custom packaging (13)

- Food industry packaging machinery (12)

- Food packaging (6)

- Bag filling machinery and equipment (3)

- Food industry - machinery and equipment (3)

- Fabrics, nonwoven (1)

- Glues, adhesives and applicators (1)

- Industrial robots (1)

- Machine tools, metal machining - parts and accessories (1)

- Package sealing machinery (1)

- Packaging (1)

- Plastic packaging (1)

- Steam polishers (1)