- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging for chemicals

Results for

Packaging for chemicals - Import export

GERBU BIOTECHNIK GMBH

Germany

This is a substrate for Immunofluorescence, enabling a highly sensitive detection of cellular surface antigen expression. A highly sensitive CLAMP method (quinone methide-based catalyzed signal amplification) can be applied to live/fixed cells or tissue sections. In this method, using ?-galactosidase-labeled secondary antibody and newly developed fluorescent dye CLAMP F405, the cells expressing a specific cell surface protein are selectively and highly sensitively stained.

Request for a quote

VIESS CLEANERS

Hungary

We welcome Private Label in our washing capsule factory. If you want your own branded product, please contact them. We offer you a number of solutions up to the production of the finished product. You can order your products in recycled plastic boxes of different colors or you can use refill packs. Our washing capsules and dishwasher capsules are high quality, 100% water soluble capsules that have the most effective washing effect. The market for washing capsules is growing more and more, start your own brand today! We help and support you in everything!

Request for a quote

HUGE PUMP

Turkey

AREAS OF USAGE: 1-CHEMICAL INDUSTRY: For transfer acids, alkalis, solvents, alcohols 2-REFINING INDUSTRY: For using as dosage, circulation pump, filter press pump 3-CERAMIC INDUSTRY: Glaze and slurry transfer 4-SHIPPING INDUSTRY : Transferring bilge, sludge and chemicals 5-COSMETIC AND PHARMACEUTICAL INDUSTRY: For transfer cream, shampoo, gel and other chemicals 6-PACKAGING INDUSTRY: Transfer and storage of products such as glue, resins, paint, varnish, ink ADVANTAGES: 1-Corrosion-resistant 2-Pumps can use for transferring fluids which contains particles 3-Maintenance is easy and costs are low 4-Flow rate can adjust with change inlet air pressure. 5-Pumps can work without fluids. 6-Suction depth is 6 meter.

Request for a quote

HUGE PUMP

Turkey

AREAS OF USAGE: 1-CHEMICAL INDUSTRY: For transfer acids, alkalis, solvents, alcohols 2-REFINING INDUSTRY: For using as dosage, circulation pump, filter press pump 3-TEXTILE INDUSTRY: Transferring textile chemicals 4-PACKAGING INDUSTRY: Transferring for glues, resins, paints, varnishes, compounds ADVANTAGES: 1-Corrosion-resistant 2-Pumps can use for transferring fluids which contains particles 3-Maintenance is easy and costs are low 4-Flow rate can adjust with change inlet air pressure. 5-Pumps can work without fluids. 6-Suction depth is 1,5 meter.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The compact 3VPHD8 Pharma Dispenser enables precise and reliable dosing of a wide variety of materials. Thanks to the special rotor-stator-geometry, no valve is required to prevent the medium from flowing out independently. Alternating opening chambers ensures gentle product transport and pulsation-free output. The VPHD series was specially developed for applications in the pharmaceutical, biotechnology, medical and food industries. Your advantages: - Interior with optimised dead space - Design according to EHEDG guidelines - FDA-compliant design/development - hygienic and pharmaceutical design - Works certificate 3.1 (DIN EN 10204) - all surfaces for pharmaceutical applications Ra ≤ 0.8 μm - retraction option (no dripping or thread pulling) - absolutely linear relationship between rotor speed and spread rate - long service life due to media-specific component selection

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The piston filler is one of the main product of Npack, most of Npack liquid filling dispenser are applying in the fields of Daily chemicals, cosmetics, Food&beverage,personal care products, pharmaceuticals, Oils products.As piston filling machine are solely based on conventional volumetric technology, these are easy to operate and relatively low cost for the majority of the end-use industries. Piston filling machine is one of the most popular liquid filling machine for its universal ability ,piston filling machine can fill thick and highly viscous products, such as chunky, semi-paste, paste products, also extensively utilized to fill chemical preparations, such as adhesives, greases, epoxies, waxes, and lubricant oils, also an optional for filling thin liquid Widely application of liquids, such as viscous liquid, shampoo, lotion,cream;Food sauce;foamy liquid,hand liquid soap,detergent. High Performance and accuracy,easy operation.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The Automatic pick and place capping machine is designed and manufactured by shanghai npack automation Equipment co.,ltd, solving the cap feeding problems and increasing the capper working efficient.The cap pick device can be driven by servo motor or a cam splitter for Synchronize working with the filling and capping. It is an ideal bottle capper for the caps which is specially and can not directly feeding on the bottles,such as the Anti-theft caps,Child Proof Caps,Sports Caps/Push-Pull Cap,Spray Caps,Pump caps etc.The whole machine was made with 304SS with dust cover, safety door, one or two capping heads are for optional, the two capping heads max speed can reach 80b/m. For different types of caps, the cap sorting device will be diffirent, we have the vibertor, centrifugal disc and elevator sorting feeder. And the bottle capper equiped with a cap storage hopper elevator for storage caps for long time working,standard one is around 0.5 cubic meters.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Single head capping machine is speically designed to meet the requirements universal screw caps,for some manufacturers have different types of caps, and do not have a big bulk production. The bottles are going on inline on a conveyor, and for different size of bottles in a wide range which are not required changeover parts, and big difference diameter or size of caps, only replacing a capping head, the replacing time takes less than 2 mins. OEM factories prefer to such a bottle capper. The capping system is driven by a servo motor, torque is adjustable, meet almost all the users needs, for different height of containers, the capping head is adjustable.The whole capper was PLC control with HMI operation. for this capper is designed for OEM and low capacity need, so we considered more flexiable of the capper working and operation, meanwhile the cost is acceptable for most of the users.

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

The ""digital watermark"" integrated into the whole packaging allows the machines in the sorting plants and the end consumer to find out more information about the packaging via an app using their smartphone. In this way, sorting plants can differentiate between food packaging and packaging for chemicals, for example, and sort them according to their intended use. Your desired article geometry can be developed individually.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

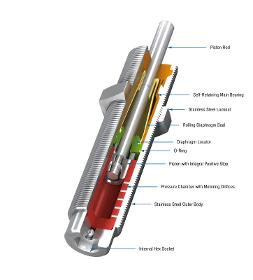

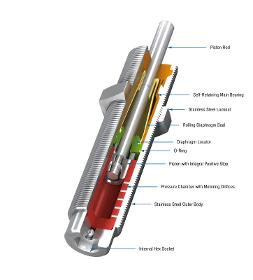

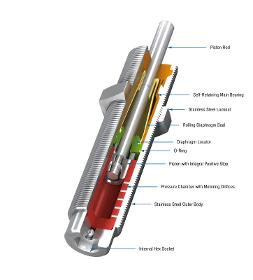

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 20 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 136 Nm/cycle Stroke 25.4 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 41 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine mod. FPMP 83 (220 V and 12 V) with dual drive, built on the basis of the mod. FPMP 82. The upper and lower dragging allows high performance on all materials. Operation with double reciprocating motion, device "antiwear" with power highly efficient even with high thicknesses and slippery materials. The sewing machine is used in agricultural, chemical, food, packaging and textile applications. Suitable for closing bags of light fabric and for coupling pieces of fabric together. The FPMP 83 is also suitable for the sewing of nets, such as those for the collection of olives or antihail. For uses other than those listed please send us a test sample of your product.

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine Mod. FPMP 82 (220 V and 12 V ) for bags particularly robust, vibration-free, usable in agricultural industries, chemical, food, packaging, textiles, for use in finishing. Suitable for sealing bags of a different type of paper, jute, fabric and plasticized, etc. such as bags of food or chemicals. The FPMP 82 can be used for the sewing of the collection nets of olives or antihail. The operation with reciprocating motion with "wear" arrangement allows a very efficient grip even on medium to high thicknesses. The machine works with standard 220 volt electric cable. It's also available in 12V that can be equipped with external battery and backpack. For uses other than those listed please send us a test sample of your product.

Request for a quote

NX PRINT & PACKAGING

Romania

Packages and labels communicate how to use, transport, recycle or dispose of the package or product. With pharmaceuticals, food, medical, and chemical products, some types of information are required by government legislation. Some packages and labels also are used for track and trace purposes. Most items include their serial and lot numbers on the packaging, and in the case of food products, medicine, and some chemicals the packaging often contains an expiry/best-before date, usually in a shorthand form.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SACCHIFICIO VENETO SPA

Italy

Packaging for the CHEMICAL sector represents the most advanced technical level. Our current customers are the clearest demonstration of our manufacturing capabilities in the industry.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

LF-5K is a linear feeder for granular materials and some powder materials. The vibratory feeding mechanism achieves multi-stage feeding. The pneumatic cylinder drives fast discharging. LF-5K linear feeder has a wide weighing range with high speed and high precision, which can be widely used in quantitative packaging machinery of grain, feed, chemical, rubber, and plastic industries.

Request for a quote

BASE GROUP SP Z O.O.

Poland

We manufacture steel or aluminium tanks and vats for wide range of industry. We provide tanks and vats according to customer drawings. Our production and welding services are in accordance with ISO 3834-2 and other certificates we own: EN 1090, EN 15085, DNV-OS-C401, 9001:2015 and ISO 14001:2015. WE can produce wide range tanks and vats according to yours drawings. At clients’ request Base Group can produce: Water Heater Tanks, Water Storage Tanks, Heat Exchangers Tanks, Stainless Steel Process Tanks, Expansion Tanks, Heating/Cooling Package Units, Food Industry Tanks, Chemical Industry Tanks.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The STS-B was developed for the simple aggregation of pharmaceutical packs into a bundle. For this purpose, the barcodes of serialized products are captured from below by the vision system through a scratch-resistant glass plate. The distance between camera and barcode therefore always remains the same. The maximum working surface is 420 mm (W) x 300 mm (D). The detected serial numbers are marked in green so that they are easy for the operators to understand. Depending on the configuration, the system can compare the recorded serial numbers with the default values of the L3 installation. Particular attention was paid to user guidance (workflow) in order to achieve maximum process reliability. In order to completely fill the carton layer(s) or spaces, barcodes that cannot be placed with the barcode facing upwards due to their orientation can be manually added in each layer by the integrated handheld scanner to complete the respective layer or carton.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

To serialize vials and other cylindrical products, we rely on the proven quality and reliability of our labelers. In order to achieve the best possible grading of the serialisation barcodes, we integrate thermal transfer printer or marking laser units directly on the label applicator. The vision system immediately inspects the print data after the printing process. If the inspection shows a negative result, we optionally offer a label reject station which automatically removes the label from the process and therefore does not waste a „good product“. Both the vision system and the print engine are fully integrated in the touch panel HMI. Shift registers in the label applicator as well as in the complete system enable product and label tracking through the complete system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The LSS-PV model was developed to serialize small product batches cost-effectively and according to the requirements of country-specific FMD guidelines. The products are fed manually. A transport system with product carriers guarantees a precise and continuously accurate alignment of the products. After the printing process performed by a thermal inkjet printing system (TIJ), the print data is inspected. If the inspection result is positive, the products are either collected on the collection table at the outfeed of the system or glide over an optionally available transfer plate into an outer shipping case. Defective products are reliably separated from the GOOD products by the product reject station. This process is verified twice in the PLC.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

s with the MS-PV-AG model, the products are fed manually by the operator. Product carriers and adjustable guide rails ensure a stable product transport. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product is removed from the process and fed to a lockable collection box. It is not taken into account during the formation of the aggregation pedigree and is ejected and marked in the shift register as soon as the error is detected. As soon as the filling quantity per carton is reached according to the specified packing scheme, the system automatically generates a serialized label for the shipping carton. It is applied manually by the operator and confirmed by a handheld scanner that the aggregation label has been applied.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The MAT model series serves as a mobile terminal for all aspects of aggregation and rework. Aggregation and rework can take place over several levels. The devices are available in the following expansion stages: MAT-C Manual aggregation and rework station (1 level) (boxes – shipping cases) MAT-P Manual aggregation and rework station (1 level) (shipping cases – pallets) MAT-CP Manual aggregation and rework station (2 level) (boxes – shipping cases – pallets)

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The STS-T series is based on high-resolution image chips and is available with resolutions of 12, 20 or 30 megapixels. With the real-time autofocus, any number of barcodes, even if they vary greatly in height, can be easily and reliably captured without mechanical or manual adjustment. For this reason, the system also finds its place in the incoming goods department of large pharmacies or re-importers (in entrance module mode). The field of view of 600 mm in width and 400 mm in depth is marked on the base frame. The shipping cases can have a height of up to 380 mm.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This powerful HSF friction feeder is the optimal solution when empty folding boxes have to be marked with variable data offline from the production line. The modular design of the system enables an easy integration of the desired marking technology. The HSF separates the folding boxes from the stack in the infeed magazine. The cartons are guided to the printing station by two parallel running belt conveyors. Print information could be e.g. serialisation data in the form of bar codes or data matrix codes and text. Depending on requirements, thermal inkjet, laser coders or label print- and apply systems can be used (also in combination). The printed data is inspected and verified by an integrated vision system. The b+b Linemanager recognized all 21CFR Part 11 data for each serial number and is able to report this back to the Siteserver system (e.g. b+b Siteserver).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The products are manually placed on the conveyor belt, printed from above and collected at the end of the system. The portable system is equipped with a Wolke m610 Touch thermal inkjet system. An upgrade to a manual serialisation system with b+b Linemanager and Full Vision System is optionally available. The conveyor belt is driven by a powerful stepper motor with constant speed. The conveyor belts are provided with crossbars at regular intervals to achieve constant product guidance and thus a consistent print result. The distance between the two toothed belt conveyors can be easily adjusted in order to process different product widths. For processing slightly slanted products, the positions of the crossbars can also be adjusted to each other.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This workstation enables the manual serialisation of drug packages and their aggregation into shipping cases. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system as it passes by and then manually placed in a shipping carton. As soon as it is filled, the downstream thermal transfer label printer creates an individual serialisation label. The correct print data and print quality are permanently monitored by a vision system. The operator places the medicine products to be serialized on a reference edge at the infeed. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product stops at a certain position marked by red LEDs. The removal of the rejected product must be confirmed by pressing a button on the HMI.

Request for a quoteResults for

Packaging for chemicals - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Chemicals and pharmaceuticals - packaging machinery (19)

- Food supplements (2)

- Packing and packaging - machinery and equipment (2)

- Sewing machines and accessories - industrial (2)

- Boxes, cardboard (1)

- Centrifugal pumps (1)

- Chemicals - Basic Products & Derivatives (1)

- Custom packaging (1)

- Electrical & Electronic Components (1)

- Gear pumps (1)

- International transport agents (1)

- Labelling machines (1)

- Laundry detergents for household use (1)

- Nuts (1)

- Paper & Cardboard - Finished Products (1)

- Pharmaceutical products (1)

- Plastic packaging (1)

- Printing (1)

- Pumps (1)

- Road transport - logistical services (1)