- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil recycling machine

Results for

Oil recycling machine - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Aluminum separators automatically pick up aluminum and steel cans from all waste collected from the recycling stations. 1. Recovery aluminum cans from plastic bottles. 2. High efficiency of recovery of aluminum from city waste.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

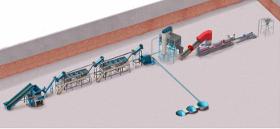

A Sand and Rubble Recycling Plant is a plant that processes and reuses demolished concrete, bricks, asphalt, and other such wastes to produce recycled products like aggregates and sand for use in construction projects. These plants used to recycle materials carry application in cities for the collection of wastes, sorting, breaking, screening, washing, and grading to get a product that may have the value for the customers. The reason may be that the aggregates produced in the plants can be used in construction by substitution for aggregates, which will lead to reduced demand for new aggregate resources and less waste landfill. As well, the recycled sand derived from the rubble may be used for applications such as construction, landscaping, and road works, providing a cleaner alternative yet ensuring the sustainability of the construction industry.

Request for a quote

TECHNIC MACHINES

Turkey

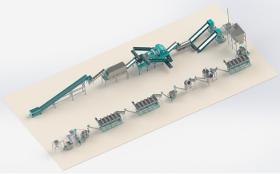

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

TECHNIC MACHINES

Turkey

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

The perfect machine to quickly and automatically return the winding material remaining on the spools to the recycling process. The spools do not suffer any damage and can therefore be used over a long period of time. Device details: ▪ Enables up to 24 braiding spools to be unwound at the same time ▪ Appropriate spools: ▫ Diameter of mandrel 23 mm (standard version) ▫ Spool outer diameter up to 100 mm ▫ Other spools with different inner and outer diameters possible ▪ Suitable for different winding materials, e.g. metal wire, plastic, natural, glass and carbon fibres

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIZAR RECYCLING MACHINES LTD.STI.

Turkey

MİZAR ASC Series is designed for reduction with shred all kinds of cables, electronic cards, (WEE), radiators, plastics, woods and tyres.

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

The system RS 6000 is a high-performing recycling system that cleans large oil volumes in several process stages. This system was constructed for many years of reliable work without service. By several process steps such as heating and settling, large amounts of water and dirt are removed. Additionally, the usage of settling technology and a pre-filter increases the service life of the main filter. The RS 6000 can be operated manually, semi- automatic, and fully automatic. It is the ideal recycling system for central treatment of, for example, cutting oil or cooling lubricants. 400 V asynchronous-motor Robust, stable gear pump Free choice of settling- and heating times and the number of filter passes Either manual, semi-automatic, or fully automatic operation Displays for operation- and process status Flow regulation for high viscosity oils Element lifter for fast filter exchange

Request for a quote

MIZAR RECYCLING MACHINES LTD.STI.

Turkey

MİZAR AC Series is designed for reduction with shred all kinds of cables, plastics, woods and tyres.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The MRS extruder processes undried PET bottle flake without any pre-treatment directly into pellets. The polymer melt is intensively and rapidly exchanged in the multiple screw section of the extruder. The huge surface area is exchanged at an unparalleled rate so that even with a moderate vacuum level of 25 to 40 mbar in the degassing section, contaminants are efficiently evaporated out of the melt. A letter of Non Objection (LNO) from the FDA underlines the decontamination efficiency. If, in order to boost the intrinsic viscosity (IV) a downstream solid state polymerisation system (SSP) is used, this can be specified far shorter than otherwise necessary as the extruder has already carried out the decontamination of the bottle flakes. The end product is of especially high quality with regard to transparency and yellowness.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For optimal waste recycling for our clients, Bezner engineers and builds waste management and recycling machinery according to customer’s recycling and sorting goals, dimensions and budget. We build both conventional components and ingeniously tailored units. Specific equipment outside our range from secondary suppliers can be included. This way, our project management team offers a turnkey solution.

Request for a quoteResults for

Oil recycling machine - Import exportNumber of results

11 ProductsCountries

Company type