- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nodular cast iron

Results for

Nodular cast iron - Import export

KUTES METAL

Turkey

MELTING UNIT– 1 • Brand: Inductotherm • Type: Dual Truck – 2.250 KW • Capacity: 3 tons/each x 4 unit MELTING UNIT– 2 • Brand: Inductotherm • Type: Dual Truck – 3.500 KW • Capacity: 5 tons/each x 4 unit

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

KARBOSIL is a product for addition of Si and C in the molten iron. It is used in the production of synthetic iron, which required lower values of sulfur and nitrogen.

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

Purpose of use: Steel castings Nodular graphite cast irons Grey cast irons

Request for a quote

ISTANBUL DOKUM SANAYI VE TICARET A.S..

Turkey

Istanbul Dokum is an organization, has flexible production methods enable to cast, iron, nodular iron, steel, stainless steel, duplex, super duplex and bronze in sand molding system in a single foundry. Our foundry, as different from the hundreds of foundries across Turkey and Europe, complex is equipped to supply castings to customers. In our induction furnaces, your orders are casted carefully with our qualified personnel. Casting cleaning is carried out by a separate team within our structure and some parts are subjected to heat treatment in accordance with special demands. We apply heat treatment in order to achieve better mechanical values depending on the end use areas. Sandblasting is done in our 2500x2500x3500(h)mm inner dimensioned sandblasting machine with a single piece capacity of 10 tons.

Request for a quote

ISTANBUL DOKUM SANAYI VE TICARET A.S..

Turkey

Cast iron, nodular iron, steel, stainless steel, bronze, duplex, super duplex sand casting production is done in our foundry.

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Ductile iron EN-GJS-600-3

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a wide range of tools for the manual and automated finishing of cast workpieces in foundries. These include cutting discs for angle grinders and stationary machines as well as roughing discs in various degrees of hardness. Resin-bonded tools and diamond grinding discs offer maximum service life and precision for the automated machining of grey and nodular cast iron. Tools for all requirements In addition to cutting and grinding discs, the range also includes mounted points and carbide burrs for straight grinders and industrial robots, which are ideal for hard-to-reach areas. A large proportion of the products belong to the PREMIUM segment, which speaks in favour of the high quality of Tyrolit tools. Advantages of the Tyrolit range: . Variety of shapes and dimensions . Long tool life and cutting ability . Consistently high performance . Above-average comfort

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Thanks to many years of experience in steel and metal processing, Tyrolit is a global leader in the steel and foundry industry, particularly in tools for automatic fettling. Modern foundries use high-tech automatic grinding machines, and Tyrolit optimises these processes economically and qualitatively with an attractive range of tools. Tyrolit offers a wide range of tools, including grinding rings, grinding segments, edge-stable resin-bonded grinding wheels and diamond cutting wheels for grey and nodular cast iron. The use of diamond enables a considerable increase in performance. Application engineers provide support in finding efficient solutions, for example when combining diamond and conventional tools. . High economic efficiency . Above-average tool life . Highest surface quality . Reduced noise and dust emissions . Clean cutting quality . Maximum product safety

Request for a quote

ANKARA BRONZ

Turkey

All our peak and ductile casting materials are imported and produced by continuous casting method. Gray and nodular cast iron bars produced by continuous casting method were started to be used from the 1960s and at the end of the stages they have been through, they have found a wide range of usage from glass industry to automotive, hydraulic parts from oil refineries, gear manufacturing to general machinery parts. The most important reason for its use, along with its wide range of advantages, is that it is economical at various ratios, depending on the sectors and the places of use, by minimizing production costs and the costs incurred due to tool wearing. Its structure is homogeneous, tightly grained and at similar hardness. Its mechanical strength is high. Its impact and wearing resistance is high. Its production with sawdust saves 50% time. It has high resistance to hydraulic and pneumatic pressures.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

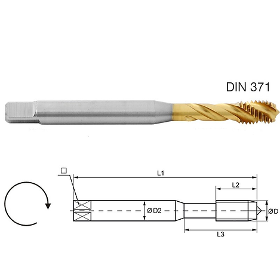

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

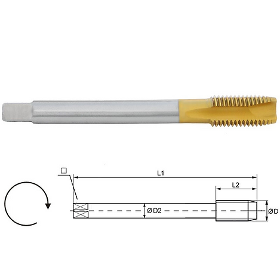

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Gear wheel, pre-machined, in various diameters, Zahnrad, material: nodular cast iron GGG-70 / EN-GJS-700-2

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

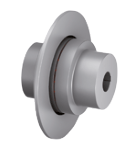

One-part design with brake disk - Brake disk made of nodular graphite iron The TSCHAN ® TNM ETW is an torsionally flexible and shock-proof claw coupling with brake disc. They compensate for angular as well as radial and axial shaft misalignment within fixed tolerances. The torque is transmitted through an elastic transitional ring. The elastic transitional ring made of Perbunan (Pb) with nitrile rubber as the base material dampens shocks and torsional vibrations, is oil-proof, insensitive to temperature and normally electrically conductive. This prevents undesirable static charging, among other things. The coupling can be used for either direction of rotation and be installed in any position. TSCHAN ® TNM ETW One part design with brake disk in nodular cast iron. Elastic intermediate ring in different hardnesses: standard Pb72, hard Pb82. General features Torsionally flexible, compensate for angular, radial and axial shaft misalignment Intermediate rings loaded in...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

One-part design with brake drum according to DIN 15431 The coupling TSCHAN ® TNM EBT is a torsionally elastic and puncture-proof claw coupling. It balances out angular, radial, and axial shaft misalignments within defined limits. The coupling transfers the torque via pressure loadable, elastic buffers of Perbunan (Pb) which are joined together as an intermediate ring. The elastic intermediate ring can cushion impacts and torsional vibrations; it is oil-tight and electrically conductive. The coupling is usable in every sense of rotation and installation position. TSCHAN ® TNM EBT One part design with brake drum acc. to DIN 15431. Brake drum in nodular cast iron, other materials on request. Elastic intermediate ring in different hardnesses: standard Pb72, hard Pb82. General features Torsionally flexible, compensate for angular, radial and axial shaft misalignment Intermediate rings loaded in compression Elastomers available in various shore hardness degrees Suitable for...

Request for a quote

MODULUS METAL

Turkey

EN 1561 / Gray (Flake Graphite): EN GJL 100, EN GJL 150, EN GJL 200, EN GJL 250, EN GJL 300, EN GJL 350 EN 1563 / Nodular (Spheroidal, Ductile): EN GJS 350 22, EN GJS 350 22 LT, EN GJS 400 15U<30mm, EN GJS 400 18, EN GJS 400 18 LT, EN GJS 400 18U, EN GJS 450 10,EN GJS 500 7, EN GJS 600 3, EN GJS 700 2 as cast & normalized, EN GJS 700 2 hardened & tempered, EN GJS 800 2 as cast & normalized, EN GJS 800 2 hardened & tempered, EN GJS 900 2 as cast & normalized, EN GJS 900 2 hardened & tempered EN 1562 Malleable : Blackheart, Pearlitic, Whiteheart ALLOY CAST IRONS Austenitic :Flake Graphite , Nodular Graphite High Silicon White Cast Iron :High Chromium, Low alloy, Nickel-Chromium CARBON STEELS Low Carbon Steels Medium and High Carbon Steels ALLOY STEELS High, Medium and Low Alloy Steels STAINLESS STEELS Ferritic, Martensitic, Austenitic, Duplex, Precipitation Hardened

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

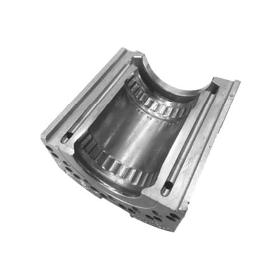

Our housings and their respective bearings form bearing units which have proven themselves in machines, plant and other equipment. Bearing housings are usually made of cast iron, on request we can deliver housings in cast steel and nodular graphite cast iron. As the bearings are usually lubricated with grease, and this first lubrication holds for quite a while, most housings don’t have re-lubrication holes. There are however, gates or markings present, so that lubrication holes can be fitted if necessary. When re-lubricating, it must be ensured that excess lubricant can escape. The bearing seating points in the housings are usually machined so that the bearings are movable, so they function as floating bearings. Fixed bearings are achieved by inserting fixing rings, if these are listed in the table. Fixing rings must be ordered separately. Housings without fixing rings are delivered as floating bearing models (L) or fixed bearing models (F).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EXOTERM-IT D.O.O.

Slovenia

EXO – COATING ZG 3V is an alcohol -based dressing. Its characteristic is a high refractoriness and a wide range of applications. Purpose of use: Aluminium and aluminum alloys, Steel castings, Nodular graphite cast irons, grey cast irons, other colored materials

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

AQUADUR M-15 is a water-based ceramic dressing in pasty form. Its characteristic is a high refractoriness. Approximate composition: about 60 % refractory filling (Al and Mg silicates, Fe oxide) about 6 % organic binder about 34 % water Purpose of use: Aluminium and aluminum alloys, Steel castings ,Nodular graphite cast irons, Grey cast irons, Other colored materials

Request for a quote

DUTCH SCRAP RECYCLING B.V.

Netherlands

Dutch Scrap Recycling B.V. Is the leading trader in Iron, Aluminium, copper, plastic, rubber , Paper, copper cathode scraps in the Netherlands and Continues to Be a Family Business With Four Generations Working to Innovate the Recycling Industry.

Request for a quote

HENGONG PRECISION EQUIPMENT

China

The chemical composition data in the table for reference only. 2. The mechanical properties comes from the sample taken from round 1/4 diameter, rectangle & square from 1/4 diagonals. 3. Customized size and grade upon your request

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Ductile iron EN-GJS-500-7

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Ductile iron EN-GJS-400-18

Request for a quote

HENGONG PRECISION EQUIPMENT

China

8% lighter than forged steel Machining allowance reduced by 30% 45% reduction in comprehensive cost Tool saving 45%-60% In 1999 Hengong independently developed the first continuous casting line. Compared with other materials, the continuous casting product has fine mic ro-matrix and high yield witho ut internal defect. Currently, Hengong is the major production base of continuous casting iron in Asia. Advantage against forged steel: 8% less weight, 30% less stock allowance, 45% less labor cost, 70% tooling cost.

Request for a quote

ADIS FRANCE

France

PARTS FOR INSTALLATION AND OPERATION ON HYDRAULIC NETWORKS cast iron universal coupling MAIN FEATURES - Body in ductile cast iron EN-GJS 400 - Blue epoxy anti-corrosion coating - Nominal pressure: 16 bar - For all types of pipe (PVC - PE - cast iron - steel) - Complies with standard EN 545 - A.C.S. certified product

Request for a quote

KUTES METAL

Turkey

-Group 1 Moulding Line : Brand : Georg Fischer Type : Impact Standard IM-S-1 otomatik yatay kalıplama hattı Dimensions : 800 x 600 x 250/250mm Capacity: 120 mold / hour Pooring Unit: Inductotherm Visipour P3 Otomatik Tundish Sand Unit : Georg Fischer Conveyor Systems: Georg Fischer Shakeout: Jöst -Group 2 Moulding Line : Brand : HWS (Heinrich Wagner Sinto) Model : Seiatsu EFA-SD otomatik yatay kalıplama hattı Dimensions : 900 x 700 x 300/300mm Capacity: 120 mold / hour Pooring Unit: HWS Otomatik döküm potası Sand Mixer: Eirich RV24 - 3000 Lt - 78 m3 mold sand / hour Sand Control Unit: QualiMaster AT1 Conveyor Systems: VHV Belt Conveyor, Jöst Vibra Conveyor Stakout : Jöst Cooling Tunnel : Jöst

Request for a quoteResults for

Nodular cast iron - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Cast iron items (15)

- Casting, steel (7)

- Iron, steel and metallurgy - import-export (5)

- Cast iron, special grade (4)

- Aluminium and aluminium alloys (3)

- Tools & Hardware (3)

- Iron and steel industry and foundries - machinery and installations (2)

- Metal joinery, wrought-iron - machinery and equipment (2)

- Abrasives, mechanical (1)

- Boilers, cast iron (1)

- Cocks and valves (1)

- Coring machinery (1)

- Couplings, mechanical (1)

- Grinding - steels and metals (1)

- Industrial valves, operating equipment (1)

- Iron, pig (1)

- Machine tools - metal machining (1)

- Milling - steels and metals (1)

- Moulds, foundry (1)

- Portable power tools (1)