- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nitrogen generation

Results for

Nitrogen generation - Import export

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

Poppe + Potthoff Maschinenbau GmbH supplies compressor units and pressure control systems of up to 400 bar for various gases. We offer ready-to-connect units to increase the existing pressure for pneumatic and hydraulic applications. In this way, the performance of existing systems can be increased flexibly and efficiently. Our compressor units are used wherever the existing system pressure is insufficient to implement specific applications. Of course, our systems are UL or CE compliant as required. In addition, we offer you service and support directly on-site.

Request for a quote

MIKROPOR

Turkey

"Pressure Swing Adsorption (PSA) type Nitrogen Generation System that is used to separate and enrich nitrogen from oxygen employs CMS (Carbon Molecular Sieve) as adsorbent. CMS adsorbs oxygen and water vapor molecules under a certain pressure while allowing nitrogen to pass through in the line. The Nitrogen Generator consists of two adsorber vessels filled with CMS. Clean and dry air is directed to one of the adsorber beds where oxygen and water vapor are adsorbed faster than nitrogen in the pore structure of the CMS, resulting in increased nitrogen purity of the product gas stream to the desired level (95-99.999% as required by customer)"

Request for a quote

MIKROPOR

Turkey

Most PSA Nitrogen Generator users require the highest levels of Nitrogen purity by the most cost-effective means possible. Mikropor’s brand new MDX Nitrogen Purifier System offers an extremely economic way to increase Nitrogen purity levels beyond 99.5% or 99.9% all the way up to 99.999% purity. The MDX range increases Nitrogen purities by utilizing a specially designed catalyst with a large surface area. As a result of the reaction on the catalyst surface, the residual oxygen content is reduced to maximum 10 ppm level. Mikropor’s MDX Nitrogen Purifiers, combined with Mikropor’s MNG Nitrogen Generators, utilise a small amount of Hydrogen gas during the reaction process to achieve high levels of Nitrogen purity by avoiding compressed air loss. The MDX System, in conjunction with MNG Nitrogen Generators, will significantly reduce power consumption and still achieve the highest possible levels of Nitrogen purity.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

It enables you to reach bright, clean, burr-free and perfect cutting quality in laser cutting. Nitroxtec laser cutting system has been produced by paying attention to the thickness, type, cutting time and laser technology of the metal being cut.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Nitrogen is one of the elements that we encounter in every aspect of our lives. It is important to ensure certain controls and separation of nitrogen, which is 78 per cent even in oxygen in the air. Nitrogen or nitrogen generators are used for procedures seen as purification processes. As a result of the use of nitrogen generators in production areas and various factories, efficient and economical use is in question. Due to the importance of nitrogen generator, it is found in many brands and types. However, the first brand and product that comes to mind when it comes to nitrogen generator is Nitroxtec nitrogen generator. Its high-end features and more successful results compared to other devices cause the machine to stand out. It is designed to provide maximum performance and uninterrupted nitrogen production. It is produced with superior technology. It works with PSA (Pressure Swing Adsorption) process.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Use 18 Bar Dry Air systems for laser cutting benches. Get rid of your nitrogen gas costs for cutting. Very high costs are paid for quality cutting in laser machines. With the 18 Bar Dry air system, you can get rid of tube and transportation costs. With the 18 Bar Dry air system, you can put an end to your tube purchase costs. With the oil-free pneumatic Booster, oil-free and dryness can be guaranteed in the cutting air. Thanks to the Activated Carbon Towers and Chemical Dryers used in the system, continuous measurement is made and provides dry and oil-free air flow.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Discover Oxygen gas production with Nitroplace’s superior quality and modern technology. PSA technology is applied in the separation of oxygen gas from compressed air. Thanks to PSA technology, you can produce oxygen gas in the range of 90% – 95% purity at a capacity of 0.5 – 385 Nm3 / h. Please contact us for our alternative products that are less costly, safe and suitable for your needs. Why don’t you produce oxygen on-site with low costs instead of buying oxygen cylinders yourself? Nitroxtec; oxygen generators have the modern technology needed to produce oxygen. Our Oxygen Generators is reliable, sustainable and cost-effective source of oxygen gas with modern PSA technology. Our oxygen generators are used in every sector where oxygen gas is needed. It is a very important option for companies that value sustainability, efficiency and profitability. Nitroxtec; It enables you to become a professional oxygen producer with on-site oxygen generators. Produce the oxygen gas yourself.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Advantages of Container Type Nitrogen Production Systems Flexibility: Container-type nitrogen (nitrogen) production systems can be adapted to different production capacities and purity levels. In this way, they can offer the solution that best suits the needs of businesses. Easy installation: Container type nitrogen (nitrogen) production systems are delivered ready for use. In this way, businesses do not need special expertise for installation. Portability: Since container type nitrogen (nitrogen) production systems are portable, they can be easily moved to different locations according to the needs of the businesses. Container type nitrogen production systems are one of the most preferred nitrogen production systems with their fl exibility and simple installation that meets the needs. Container type nitrogen production systems are a perfect solution for businesses, thanks to their portable and ready-to-use features.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Deoxy Nitrogen purification units are devices used to separate nitrogen in the air from oxygen, carbon dioxide and other gases. The purification process is done by taking advantage of the differences between the molecular sizes and physical properties of the gases in the air. In the catalyst unit, palladium-coated alumina binds externally introduced hydrogen gas atoms. The remaining (1,000 ppm) oxygen gas molecules in the 99.9 purity nitrogen gas produced in the PSA generator combine with hydrogen gas on palladium alumina and turn into water, thus raising the nitrogen gas to an ultra-pure level. The water in ultra-pure nitrogen gas is dried with the help of a special desiccant dryer, and ultra-high purity 99.9999 (1ppm O2) nitrogen gas, purified from oxygen and moisture, is transferred to the systems. A special automation system is used to ensure the most efficient and minimal consumption of hydrogen gas used in the catalys.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Container Type Oxygen Production Solutions Oxygen is an indispensable gas for human life. It is widely used in medical, industrial and many other fields. Container type oxygen production systems for oxygen production are one of the most preferred solutions for businesses. Advantages of Container Type Oxygen Production Systems Flexibility: Container-type oxygen production systems can be adapted to different capacities and needs. In this way, it offers the most suitable solution for the needs of businesses. Easy installation: Container type oxygen production systems are very easy to install. In this way, it allows businesses to start producing oxygen in a short time. Portability: Container type oxygen production systems are portable. In this way, it can be moved to different points according to the needs of the businesses.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

Heated type blower chemical air dryers are devices used to remove moisture from compressed air. These devices are pressurized It dries the air in two stages. In the first stage, compressed air passes through a column filled with silicagel, a desiccant substance. Silicagel dries the air by absorbing moisture in the air. In the second stage, a heated blower dries the silica gel, making it ready to absorb moisture again. The most important feature of heated type blower desiccant air dryers is that they do not use compressor air. Blower and high efficiency with the support of the heater, waste air is sucked and heated fully automatically. Thanks to the high-tech PLC (electronic control) dew point and heating/regeneration are adjusted and moisture is removed in the most efficient way. Reduces air loss. Conventional desiccant dryers use dried air during regeneration and compressed air causes loss. Heated type blower desiccant air dryers use atmospheric air during regeneration.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

With professional and modern technology, High Pressure Desiccant Air Dryers with a capacity of up to 300 bar can be produced according to the needs of your production facility. Compressed air may contain various undesirable contaminants such as water vapor, oil, particles and dust. If polluted air comes into contact with equipment in the production process, it causes equipment damage. Features of High Pressure 50Bar Desiccant Air Dryers Standard Accessories: It has electronic control feature. Long-life pneumatic valves of European origin Superior performance active alumina American and Japanese made exhaust air silencers Inlet and outlet air filters Zero air loss water discharge system at the entrance Optional accessories: Dewpoint sensor and Energy saving mode Maximum Working Pressure: 50Bar-300Bar varies depending on the models. Regeneration air loss rates: -40 Dewpoint: 2.7% -70 Dewpoint: 5.4% Our High Pressure Desiccant air dryer models have a 2% air loss rate.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLAIRMO APS

Denmark

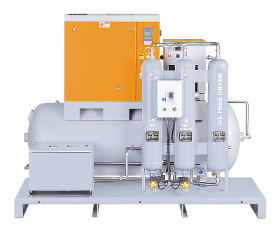

High quality nitrogen generator with integrated long life oil-free compressor. Mounted in noise reduction cabinet. Optional integrated oxygen sensor. Features Long Life & Low Maintenance Easy Installation Modbus TCP/IP VNC connection for display (Remote Connection) “Plug and Play” – CE marked

Request for a quote

FLAIRMO APS

Denmark

High quality nitrogen generator for external air supply. Mounted in ruggedized stainless steel cabinet. Optional integrated oxygen sensor. Floor mounting. Features Modbus TCP/IP VNC connection for display (Remote Connection) “Plug and Play” – CE marked

Request for a quote

FLAIRMO APS

Denmark

High quality nitrogen generator for external air supply. Mounted in ruggedized stainless steel cabinet. Optional integrated oxygen sensor. Wall or floor mounting possible. Features Modbus TCP/IP VNC connection for display (Remote Connection) “Plug and Play” – CE marked

Request for a quote

FLAIRMO APS

Denmark

High quality Nitrogen Generator with integrated oil-free compressor. Mounted in ruggedized stainless steel cabinet. Wall or floor mounting possible. Features Long Life & Low Maintenance Easy Installation

Request for a quote

DÜRR TECHNIK GMBH & CO KG

Germany

Compact nitrogen gas generator HF30N Integrated nitrogen storage within the unit With the new nitrogen generators HF30N and HF60N Dürr Technik is expanding its portfolio in the field of analytical applications. The HF30N and HF60N nitrogen generators are ideal for use in laboratories that already have a central compressed air supply or where a source of clean compressed air is available at the place of use. HF30N and HF60N are optimised for the current LC-MS systems (liquid chromatography/mass spectrometry), which are increasingly used in laboratories for analysis. Thanks to their compact design and low weight, the nitrogen generator can be mounted on the workbench or underneath. Efficient nitrogen separation ensures a reduced total air requirement and at the same time ensures the production of high purity nitrogen. This results in lower real operating costs and a reduced carbon footprint.

Request for a quote

DÜRR TECHNIK GMBH & CO KG

Germany

F30A - the most reliable LC-MS Nitrogen Generator nitrogen purity: up to 99 Nominal power: 1,7 kW Efficient and innovative - designed for your laboratory Ideal for use in laboratories where a dependable and affordable source of nitrogen is essential and is suitable all laboratories Premium compressor with state-of-the-art control Unique nitrogen generation solution for your laboratory including advice, customization and a full installation and support service. With the HF30A, Dürr Technik expands its range of nitrogen generators for your analytical applications. Our HF30A nitrogen generator is ideal for use in laboratories where a dependable and affordable source of nitrogen is essential and is suitable all laboratories, especially where a high pressure clean air source is not available at the point of use.

Request for a quote

IGRAIN - EYE-GRAIN APS

Denmark

The CROP-PROTECTOR Nitrogen Generator is used for efficient infestation control. By flushing the stored crop with Nitrogen and reducing Oxygen levels, all insects, mites and fungi will be paralyzed and terminated in the Oxygen depleted environment. The Nitrogen Generators use a Pressure Swing Adsorption (PSA) system to generate the Nitrogen. The Nitrogen is distributed into storage contailers or silos via a standard manifold and hoses. The Nitrogen Generators are used together with the iGRAIN sensor system to monitor the flushing process and the condition of the crop. Especially effective for preservation of: Barley Beans Canola Coffee beans Fruits Lentils Maize Nuts Pasta Rice Wheat See video: https://vimeo.com/903247370

Request for a quote

TETHYS OIL SUPPLIES & SERVICES

Malta

Nitrogen generators produce nitrogen gas from compressed air and offer a cost-effective, reliable and safe alternative to traditional nitrogen gas supplies such as cylinder or liquid. Nitrogen generators are available in 20 standard models with capacity in the range from 1 - 1800 Nm3/hour from 95% to 99.9995% purity. Oxywise PSA generators are designed for 24/7 operation. The touchscreen control has user friendly interface with automatic start/stop function based on gas consumption. Medical Oxygen Generators produce gaseous oxygen from compressed air on site and offer a cost-effective, reliable and safe alternative to traditional oxygen gas supplies such as cylinders or cryogenic liquid. Medical Oxygen Generators are available in several standard models with a capacity ranging from 0.4 to 150 m3 / hour at 93-95% purity. The design is made for round the clock 24/7 operation. Each oxygen generator is equipped with an automatic start & stop function, enabling the generator t

Request for a quote

CHROMALYTIC LTD

United Kingdom

Please see our website for full technical details and all products in the range.

Request for a quote

SYGASTEC GMBH

Germany

for more Information pleasee see our web page https://www.sygastec-gmbh.com/cms.html

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

LPHC are , an acrylic-aluminium made humidification chambers designed to work with our Mini One microclimate generator. LPHC is offered in two standard sizes and also can be built as a special order in different sizes by client request. The body is made of black acrylic with aluminium and front doors from clear acrylic. RH levels are controlled through the Mini One microclimate generator. UNDER CONSTRUCTION CUSTOM STAINLESS STEEL CHAMBERS We are also offering special order microclimate chambers build to client specifications. Those units are constructed from stainless steel and depend on client expectations. All aspects of microclimate can be controlled: relative humidity, temperature and low level of oxygen can be attained. Chambers with controlled relative humidity and temperature can be built with glass doors (as in photo). Units with modified oxygen have solid, special sealed doors. Low level oxygen is generated using nitrogen generator or liquid nitrogen.

Request for a quote

AGGREKO CANNOCK

United Kingdom

Our 1375 kVA gas generators are cost-effective, low emission generators. Whether you need reliable off-grid power or wish to implement a combined heat and power package - we can help. Data is based on 50 Hz. For more information please request a data sheet. Generator shown may not be representative of equipment available at the time. Our 1375 kVA gas generators significantly lower nitrogen oxide (NOx), carbon monoxide (CO) and particulate matter (PM) emissions. Both the generator and skid are housed in a space-saving 20ft ISO container. Can be run with natural gas, biogas, coalbed gas, shale gas and wellhead gas. Extensive fleet of transformers available for operation at low voltages up to 33 kV. Supporting ancillary equipment allows a wide range of gas supply pressures to be accepted. Heavy-duty, turbo-charged, after-cooled engines are suitable for continuous operation in harsh environments. Supported by a highly-skilled and experienced team of engineers.

Request for a quoteResults for

Nitrogen generation - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Air compressors - Tools and accessories (14)

- Nitrogen (8)

- Electricity generators (4)

- Air treatment - equipment and systems (2)

- Compressors (2)

- Generating units (2)

- Lubrication equipment and machinery (2)

- Biomass energy - production (1)

- Compressed air tools and systems (1)

- Filtering equipment and supplies (1)

- Gas - production plants (1)

- Measurement and control instruments (1)

- Medical treatment (1)

- Monitoring and control equipment (1)

- Oil and gas exploration services (1)