- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel & metals

Results for

Steel & metals - Import export

ACEROS METAL TREATMENT

Netherlands

Innogel B450 is a special stainless steel cleanser that removes rust easily form stainless steel. Innogel B450 is a user-friendly, green gel and is suitable for intensive cleaning of contaminated surfaces.

Request for a quote

ACEROS METAL TREATMENT

Netherlands

Innospray B600 is a ready to use cleaner for waterproof surfaces. It is highly suitable for removing (grease) stains and fingerprints. By first spraying Innospray B600 on a microfiber cloth and then wiping the stainless steel it will dry up streak-free. It is easy to use and suitable for daily cleaning of waterproof surfaces like handrails, elevators, kitchens et cetera.

Request for a quote

ACEROS METAL TREATMENT

Netherlands

Innopolish B520 is a liquid specialized cleaner, metal polish. Innopolish B520 is suitable for cleaning contaminated and dull surfaces. Suitable for stainless steel, nickel, copper, bronze, chrome and aluminum. Bring back the shine with Innopolish B520.

Request for a quote

ACEROS METAL TREATMENT

Netherlands

Innocare B580 is a neutral and mild cleaner and highly suitable for cleaning stainless steel. Next to the cleansing properties and removing the dislodged oxides and contaminations this product will provide a nano scale protective layer in order to prevent new corrosion as much as possible. Innocare B580 is powerful stainless steel cleaner suitable for the daily maintenance of lightly contaminated surfaces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WELMAN METAAL

Netherlands

International steel trade, angle equal, angel unequal. Transport included.

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

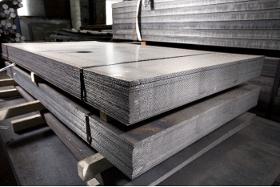

Sheet metal handling and lifting steel plates with vacuum technology. Both magnetic and non-magnetic sheets are easily lifted. The suction pad is placed on the metal product, after which the vacuum is activated by a push on the button. Now you can lift, move, or even turn the sheet metal. Vacuum lifting is used during production, storage, internal transport, transhipment, and construction. Besides vacuum lifters for metal plates, we also design pipe handling equipment. All our designs are custom made to perfectly match the individual situation. Why choose lifting plates by vacuum? Vacuum offers unique advantages compared to other lifting methods to lift plates, such as chains, clamps, and magnets. Chains and clamps can be used to lift non-magnetic plates, such as aluminium, copper, and stainless steel. Compared to these lifting methods, vacuum offers distinct advantages: No damage to the plate, not even scratches No spacers or stoppers required Easy and fast handling Less manpower

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Proper bending of aluminium and magnesium requires specific knowledge of the material. The phase in the process in which the material is bent is also crucial to the final result, right after pressing or only after hardening, for example. There are many techniques for bending, such as roll forming, press (brake) bending, swivel bending, deep drawing, stretch forming, and 3D bending.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Anodizing, galvanizing, passivation, painting: Mifa offers customers all possible surface treatments. A good surface treatment can protect against corrosion, reduces wear or friction, can be electrically insulating or conductive, and in many cases makes the product visually more attractive. Mifa sees surface treatment as the nishing touch that not only increases durability but also adds extra functionality to the aluminium product. The main surface treatments for aluminium that Mifa offers can be roughly divided into three categories: - Conversion layers: aluminium passivation, anodizing, and plasma electrolytic oxidation - Galvanic coatings: chemical nickel-plating, silver, gold, tin, hard chromium etc. - Organic coatings, painting, paint primers, adhesive primers CVD (Chemical Vapour Deposition), PVD (Physical Vapour Deposition), and synergistic coatings can also be applied on request.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

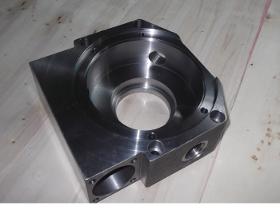

Mifa has an extensive range of modern CNC-controlled machinery. Nevertheless, we prefer to use machining work as little as possible. Thanks to the combination of precision extrusion, CNC machining, and surface treatment, we can shorten the total production time for machining and improve the quality of the product. We write the software ourselves and make our own moulds for the CNC machining. Every profile is different and often demands a specific processing method, particularly if it is a visible surface. To this end, we use CAD/CAM programmes such as Solid Works, Solid Edge, and Unigraphics. We also develop the clamping tool ourselves too. The right clamping method is crucial in order to achieve the desired result. The best clamping method is dependent on factors including the dimensions and thickness of the profile and the processes to be implemented. For more text and explanations about our CNC and aluminium machining possibilities, please contact us.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

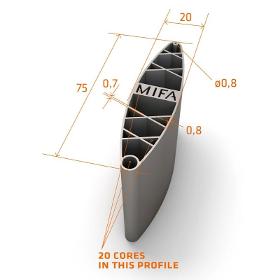

EN-755-9 and EN-12020-2 are the accepted norms for the extrusion of aluminium profiles. They allow deviations of 0.15 mm or more. Mifa ignores these norms and applies precision extrusion of 0.02 mm. We’re unique in the world! And it gives countless possibilities. Bulk production. Standardised work. Inaccurate. These are words that you’ll hear often if you ask engineers for the features of extrusion. But there is another option. Mifa’s delivery starts from 10 kg, and we offer custom-built products and precision, also for straightness, torsion, concentricity, parallelism, surface roughness and tting. Add to this the outstanding features of aluminium – post-processing is often not needed – and it becomes clear that precision extrusion would be useful for many applications. Even as a replacement of other techniques and materials.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

Netherlands

Material: ASTM, JIS, DIN, BS, iron, steel, aluminum, manganese, carbon steel, stainless steel, etc. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quoteResults for

Steel & metals - Import exportNumber of results

16 ProductsCountries

Company type