- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silicone

Results for

Silicone - Import export

DDC - DUTCH DESICCANTS COMPANY (CANADACO B.V.)

Netherlands

Silica gel bulk has a range of possible applications: Industrial solutions Relative humidity buffer (RH buffer) Filtration systems Electronic equipment Making dried flowers Ozone filters Air dehumidifiers Etc. Silica Gel Bulk orange features a moisture indicator. When the moisture percentage exceeds 20% RH, the granules will turn from orange to green/blue. When the silica gel is saturated and has attained a green/blue colour, the granules can be heated (up to a maximum temperature of 80 °C; higher temperatures than that would destroy the silica gel granules) until they have turned orange once more. In this manner, the silica gel granules can be reused. The orange silica gel is environmentally friendly and harmless. The gel does not contain any heavy metals as indicator and is free of DMF (dimethyl fumarate).

Request for a quote

RHIMEX.COM

Netherlands

Silicone profiles are made of liquid plastic rubber and can withstand temperatures from 60 to +280 degrees Celsius. Available in various colors Resistant to heat and cold Durable material and very flexible Very versatile

Request for a quote

RHIMEX.COM

Netherlands

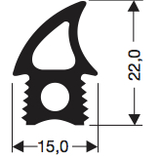

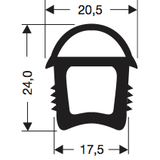

These sealing profiles are used to finish sharp edges and also to seal gaps. The profiles usually consist of PVC with a bulb of moss rubber, but profiles in EPDM and silicone are also possible.

Request for a quote

RHIMEX.COM

Netherlands

RENOVATION SEALS FOR WINDOWS AND DOORS Brush seals - Window seals - Sash rebate seals - Edge protection seals - Adhesive seals - Foam rubber seals - Steel frame seals - Door seals - U-profiles More than 2.000 profiles from EU stock. New tooling starting at EUR 95.- Delivery time 2/4 weeks. Several standard colours available. From 35 / 85 shore

Request for a quote

RHIMEX.COM

Netherlands

We supply various types of SEBS - EPDM / Silicon and EPDM rubber products of the highest quality. SEBS is a thermoplastic elastomer (TPE) with hardnesses between 20 and 85 shore A. They are also called technical rubbers, synthetic rubbers or elastoplastics, but then added with syrene. In our range you will find a wide range of rubber products, but we are also happy to be of service with customized SEBS rubber. Advantages of SEBS rubber SEBS rubber is comparable to EPDM, but has the advantage that small series can be made for a favorable price. Another big advantage is the resistance of this material. For example, SEBS rubber is UV and ozone resistant and resistant to extreme heat and cold. This ensures that this type of rubber is very widely applicable. SEBS has been described by Greenpeace as an acceptable alternative to PVC in toys. Polyethylene (PE) and Polypropylene (PP) are the most commonly used building blocks for SEBS.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENBI PLASTICS & SILICONES BV

Netherlands

The use of silicone in products has many advantages: the material is elastic, durable, and resistant to chemicals and high temperatures. As a result, the injection moulding of silicone has many applications, for instance in the medical world. For the injection moulding of silicone we are able to employ machines with a clamping force of between 25 and 100 tons. In this way we can produce units of less than a gram up to about 100 grams, varying in hardness from 10 Shore A up to about 80 Shore A.

Request for a quote

ENBI PLASTICS & SILICONES BV

Netherlands

Liquid Silicone Rubber (LSR) is a liquid silicon material, which is processed with an injection moulding process. Thanks to its special materials and processing properties, LSR offers unique design and production opportunities for Enbi Plastics. LSR has numerous uses in different industries, including health care, food, automotive, household appliances, and other sectors. For the injection moulding of silicon, Enbi Plastics uses machines with a closing force between 25 and 110 tons. This way we produce products made of components weighing from less than a single gram to approximately 100 grams, and which vary between <10 Shore A to approximately 80 Shore A in hardness, using both 1K and 2K injection moulding processes. Would you like to know more about LSR and how it can benefit your products or components? Our experts at Enbi Plastics love to help you with all your questions about LSR. Feel free to contact one of our specialists today.

Request for a quote

DSU REFRIGERATOR GASKETS

Netherlands

Summary 41-SIL per meter Black

Request for a quote

DSU REFRIGERATOR GASKETS

Netherlands

Summary 42-SIL per meter Transparent

Request for a quote

DSU REFRIGERATOR GASKETS

Netherlands

Summary 43-SIL per meter Dark grey

Request for a quote

DSU REFRIGERATOR GASKETS

Netherlands

Summary 50-SIL per meter Light grey

Request for a quote

DSU REFRIGERATOR GASKETS

Netherlands

Summary 45-SIL per meter Dark grey

Request for a quoteResults for

Silicone - Import exportNumber of results

13 ProductsCountries

Company type