- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- board manufacturing

Results for

Board manufacturing - Import export

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Quality control and testing is the most important step in the production cycle. Aiming to meet the set requirements for production. Ensure product quality and sustainability by implementing good quality control methods. As machines are busy manufacturing, there are multiple parameters that can influence the product quality. Certain factors include humidity, adhesives, board styles or flute types. Based on these parameters, product recipes must be adapted to meet the requirements. To measure cardboard strength, large EOL testing machines are used for quality control. By using a portable, easy to use cardboard tester for bend strength, cardboard can be adequately tested at any location.

Request for a quote

ONE2ID B.V.

Netherlands

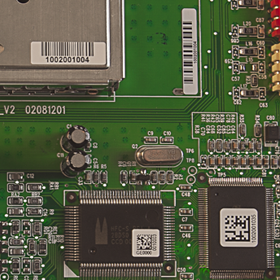

ONE2ID’s high-quality polyimide (Kapton®) labels can withstand high temperatures and are resistant to the chemicals most commonly used in the manufacturing of printed circuit boards (PCB). This type of label material is specifically designed to endure extremely high temperatures as well as aggressive chemicals. Circuit board labels can be applied either before, during or after the printed circuit board manufacturing process. A combination of strong adhesive qualities and resistance to heat and harsh chemicals protects the barcode code in order to retain its legibility for both the human eye and scanning equipment. The several layers that make up the label stay intact with the label firmly attached to the surface, even during exposure to aggressive chemical solvents. In short, polyimide labels are the perfect choice for circuit board identification.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Board manufacturing - Import exportNumber of results

2 ProductsCountries

Company type