- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium processing

Results for

Aluminium processing - Import export

MIFA ALUMINIUM B.V.

Netherlands

Mifa has an extensive range of modern CNC-controlled machinery. Nevertheless, we prefer to use machining work as little as possible. Thanks to the combination of precision extrusion, CNC machining, and surface treatment, we can shorten the total production time for machining and improve the quality of the product. We write the software ourselves and make our own moulds for the CNC machining. Every profile is different and often demands a specific processing method, particularly if it is a visible surface. To this end, we use CAD/CAM programmes such as Solid Works, Solid Edge, and Unigraphics. We also develop the clamping tool ourselves too. The right clamping method is crucial in order to achieve the desired result. The best clamping method is dependent on factors including the dimensions and thickness of the profile and the processes to be implemented. For more text and explanations about our CNC and aluminium machining possibilities, please contact us.

Request for a quote

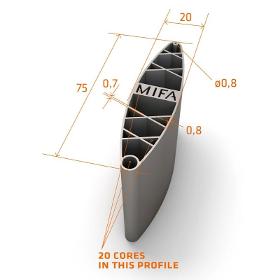

MIFA ALUMINIUM B.V.

Netherlands

EN-755-9 and EN-12020-2 are the accepted norms for the extrusion of aluminium profiles. They allow deviations of 0.15 mm or more. Mifa ignores these norms and applies precision extrusion of 0.02 mm. We’re unique in the world! And it gives countless possibilities. Bulk production. Standardised work. Inaccurate. These are words that you’ll hear often if you ask engineers for the features of extrusion. But there is another option. Mifa’s delivery starts from 10 kg, and we offer custom-built products and precision, also for straightness, torsion, concentricity, parallelism, surface roughness and tting. Add to this the outstanding features of aluminium – post-processing is often not needed – and it becomes clear that precision extrusion would be useful for many applications. Even as a replacement of other techniques and materials.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnets for recycling separate ferrous and non ferrous metals from waste streams or bulk streams. For the elimination of impurities from raw materials or recovery of valuable metals from product streams. An overband magnet effectively and quickly separates high volumes of iron or steel and hangs above a flat or trough-shaped conveyor belt. This type of magnet is self-cleaning and continuously draws Ferro parts from a material flow. he iron removal efficiency of overband magnets ranges from 70 to 90%. This depends on magnet design, product flow and placement. We also manufacture Eddy current separators which remove non-ferrous metal particles, such as copper and aluminium, in a continuous process. For the recovery, recycling or removal of metals.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Aluminium processing - Import exportNumber of results

3 ProductsCompany type