- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- multi axis systems

Results for

Multi axis systems - Import export

FÖHRENBACH GMBH

Germany

With high demands on accuracy and dynamics, the base frame in welded construction or hard stone is also a possible and reasonable part of the scope of supply. Here, all axes are specified, assembled, aligned, measured, tested and recorded - according to desired specifications. By means of hard stone, the required accuracies can be achieved. Hard stone offers all the characteristics required - ranging from a small coefficient of expansion, high abrasion resistance, optimum vibration damping, absence of unwanted residual stresses up to the necessary accuracies regarding flatness, parallelisms and angularity.

Request for a quote

ROLLON GMBH

Germany

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

IGUS® GMBH

Germany

Overview for triflex® advantages Other information triflex® RSP Continuously adjustable retraction force triflex® RSP triflex® RSE Infinitely adjustable retraction force for small robots triflex® RSE Triflex® R-Set Universal module for all motions on the robot Triflex® R-Set Fiber rod modules Intelligent problem solution through directed pretension. Fiber rod modules Universal assembly kit Offers the potential to mount the fiber rod module in the desired position on the robotic arm. Universal assembly kit Strain reliefs for large cross sections Secure mounting also in the use of cables with large cross section. Strain reliefs Gliding feed-through Available with and without swivel bearing Gliding feed-through Protectors Well protected in extreme applications. Protectors Heat shield Protection against weld and metal spills up to 600°C Heat shield CF Robot special cables Special cables for long service life in robotic applications. CF Robot special cables iF-Design Award for "TRC"- and "TRL"-Design Cleanroom environments on request Series TRC electrically conductive ESD/TEX versions possible UL94-V2classification Overview for triflex® advantages Other information Application examples Interesting applications from a variety of industrial sectors Triflex® R Configure interior separation Define cables, select chain and configure interior separation. Now also for all Triflex® R series! Internal separation configurator Triflex® R QuickRobot Equipment support for various types of robots. Simplified ordering of complete systems. QuickRobot TRC.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm Bending radius R: 50 mm Pitch: 11.3 mm e-chain® TRC.40 Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13,9 mm e-chain® Installation instructions Instructions for the joining and separating of the triflex® R - TRC. Assembly Instructions TRC.60 Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® TRC.70 Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain® TRC.85 Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRC.100 Inner height Bi 1: 37.5 mm Inner height Bi 2: 32.5 mm Bending radius R: 145 mm Pitch: 34.5 mm e-chain® TRC.125 Inner height Bi 1: 43,3 mm Inner height Bi 2: 43,3 mm Bending radius R: 182 mm Pitch: 44,6 mm e-chain® Standard mounting bracket for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRCF.85 Inner height Bi 1: 30 mm Bending radius R: 135 mm Pitch: 30.6 mm e-chain® TRCF.100 Inner height Bi 1: 37,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting bracket for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRE.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm Bending radius R: 50 mm Pitch: 11,3 mm e-chain® TRE.40 Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13,9 mm e-chain® Installation instructions Instructions for the joining, separating and filling of the triflex® R - TRE. Assembly Instructions TRE.60 Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® TRE.70 Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain®. TRE.85 Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRE.100 Inner height Bi 1: 37,5 mm Inner height Bi 2: 32,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® TRE.125 Inner height Bi 1: 43,3 mm Inner height Bi 2: 43,3 mm Bending radius R: 182 mm Pitch: 44,6 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRE.40.B Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13.9 mm e-chain® TRE.60.B Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® Assembly instruction Instructions for the joining, separating and filling of the Triflex® R - TRE-B version. Assembly instruction TRE.70.B Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain® TRE.85.B Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRE.100.B Inner height Bi 1: 37,5 mm Inner height Bi 2: 32,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket Assembly tool triflex® R B-version Assembly tool for disassembly of triflex® R B-version Assembly tool triflex® R B-version TRL.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm bending radii R: 50 mm Pitch: 11,3 mm e-chain® TRL.40 Inner height Bi 1: 15 mm Bending radius R: 58 mm Pitch: 13.9 mm e-chain® Installation instructions Instructions for the joining, separating and filling of the Triflex® R - TRL. Assembly Instructions TRL.60 Inner height Bi 1: 23 mm. Bending radius R: 87 mm. Pitch: 20.4 mm e-chain® TRL.70 Inner height Bi 1: 28 mm Bending radius R: 110 mm Pitch: 25.6 mm e-chain® TRL.100 Inner height Bi 1: 38 mm Bending radius R: 145 mm Pitch: 34.5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRLF. 65 Inner height Bi 1: 24.4 mm Bending radius R: 100 mm Pitch: 23.1 mm e-chain® TRLF. 85 Inner height Bi 1: 32.8 mm Bending radius R: 135 mm Pitch: 31 mm e-chain® Assembly instruction Instructions for the joining, separating and filling of the Triflex® R - TRLF. Assembly instruction TRLF. 100 Inner height Bi 1: 38 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket triflex® RSP Continuously adjustable retraction force triflex® RSP triflex® RSE Infinitely adjustable retraction force for small robots triflex® RSE Triflex® R-Set Universal module for all motions on the robot Triflex® R-Set Fiber rod modules Intelligent problem solution through directed pretension. Fiber rod modules Universal assembly kit Offers the potential to mount the fiber rod module in the desired position on the robotic arm. Universal assembly kit Strain reliefs for large cross sections Secure mounting also in the use of cables with large cross section. Strain reliefs Gliding feed-through Available with and without swivel bearing Gliding feed-through Protectors Well protected in extreme applications. Protectors Heat shield Protection against weld and metal spills up to 600°C Heat shield CF Robot special cables Special cables for long service life in robotic applications. CF Robot special cables This system is especially suited for: First choice for multi-axis industrial robots Three versions are available: TRC: closed design; TRE: "Easy" design, very easy to fill in from outside; and TRL: the "Light" version, likewise with "easy" design Universally applicable in general mechanical engineering Secure energy supply system Multi-axis (3D movements) High torsional stability Can be shortened and lengthened as required due to the individual elements Large filling space Doesn't get stuck in the interfering edges Small bending radius Simple cable routing for three-dimensional applications with ball-and-socket system for absorption of high tensile strength Cables easy to install and replace (TRE/TRL version) Fiber rod module for partial reinforcement and to give direction TRL - One-piece element, extremely light High tensile strength without additional elements like steel cables, spring elements, etc. Typical industrial sectors and applications First choice for industrial robots Machine tools Handling equipment 6-axis Material handling system General mechanical engineering iF-Design Award for "TRC"- and "TRL"-Design Cleanroom environments on request Series TRC electrically conductive ESD/TEX versions possible UL94-V2classification

Request for a quote

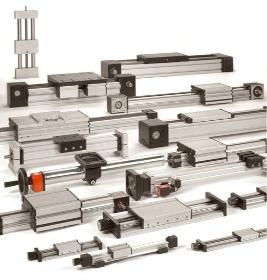

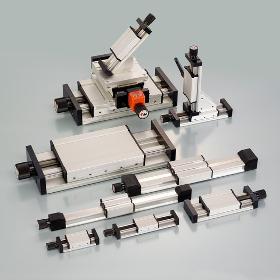

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The fields of application for our linear stages LT and PT are widely spread. They are used where highest requirements on straightness deviations, noise behaviour or positioning accuracy are demanded. Stepping motors and backlash-free recirculating ball spindles are used as standard drive. Due to the usage of selective cross roller guides, highest accuracys are achieved which are recorded in the final check. For the adaption and mounting of the linear stages, several threads in grid layout are provided so that they can be combined to multi-axis positioning systems.

Request for a quote

GETOTEC

Germany

precision slides with ball screws or trapezoidal screw drive. - Three sizes – 100, 155 and 225 - Cover variants – sheet or bellows cover - Traversing carriage available in two lengths - Various stepper and servo motors, controllers, special versions such as - Motor deflections via timing belt drive make the precision slides universal can be used and are optionally available with or without motor. - Integrated limit switches (inductive proximity switches) with cable entry or plug connection in the endplate. - Base plate and end plates are made of a surface-treated and high-strength aluminium alloy. - Modular use, e. g. as multi-axis systems

Request for a quoteResults for

Multi axis systems - Import exportNumber of results

15 ProductsCountries