- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moulds for presses

Results for

Moulds for presses - Import export

HIDROMEC SRL

Italy

Hydraulic cylinder applications in the stationary industrial sector are diverse: hydraulic presses of all kinds, ranging from presses for sheet metal forming and presses for the plastics industry to filter presses and scrap presses. Roll forming machines are also included, as well as machines and industrial equipment of various kinds. Equipment in constantly changing shapes and sizes gives us the opportunity to apply the design know-how we have acquired over forty years of dedication to meeting a wide variety of customer requirements. Hidromec develops hydraulic cylinders and systems for equipment with applications in the industrial sector that are powerful, durable and comply with the relevant environmental standards.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

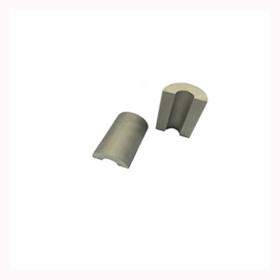

Features: Made of ground sintered SmCo magnet Powder is mixed with resin and molded like NdFeB bonded magnet No need to be coated because it is difficult to erode and oxidize High-BH (maximum) High-Br and Hc with high-operating temperature, low-temperature coefficient, counter-demagnetization, decay resistance Main products cover SmCo5 and Sm2Co17 magnets, samarium cobalt powder, various assemblies and more OEM orders are welcomed Applications: Widely used in motors, watches, transducers, instruments, positional detectors, generators, radars and more High quality, competitive price, best service

Request for a quote

ISOVOLTA AG

Austria

Prepreg with a modified phenolic resin system specially developed for processing in presses (crushed core) where short processing cycles can only be achieved through higher cure temperatures with lay-ups and de-moulding in presses that are still hot (hot in / hot out).

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

We supply tailored, special parts manufactured with our state-of-the-art cold-moulding and extrusion equipment. We can press cold-moulded articles – whether solid, semi-hollow or hollow – according to your drawings. Complex moulded parts and individual, special projects are our strengths. Our cold-moulding competence covers flanged bolts, studded parts, stepped bores and parts with an internal or external thread. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

AAAGILER GMBH

Germany

Typical fields of application for our vibration damping mats include: - Heavy machine tools - Injection molding machines - Hydraulic systems / hydraulic presses - Punching machines / punch presses / automatic punch presses - coining presses - Die hammers - transformers - generators - Transport carts / truck trailers - Sensitive measuring, electronic and testing equipment, e.g. precision balances and microscopes - Vibration isolation of machine foundations - Vibration and noise damping of rails installed in the track system (high-speed trains, subways, streetcars)

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Pancake coiled copper tube which is named for its coiled style, is widely used on the connecting for the separated air-condition. On the other hand it is used in water distribution systems, chilled water mains, drainage and vent systems, heating systems (includingsolar), fuel-oil systems, oxygen systems also in non-flammable medical-gas systems. They are produced that Copper fluid is casting to the billet moulds and follows to the extrusion press, after annealed tubes are drawing, to be copper tubes. They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

We offer a wide range of rods, which are used for electroplating, switchgear, ship building and power generating equipment, as they are high-conductivity. On the other hand, they are widely used as radiator in electrical product, as its high- thermal conduction. They are produced that copper fluid is casting to the billet moulds and follows to the extrusion press, after that annealed rods are drawn, to be copper rods, 2000 mm to 6000 mm length, 10 mm to 175 mm diameter and they are according with TSE 435, DIN EN 12163 and DIN EN 13601. General properties material with minimum copper content 99.95%

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Pancake coiled copper tube which is named for its coiled style, is widely used on the connecting for the separated air-condition. On the other hand it is used in water distribution systems, chilled water mains, drainage and vent systems, heating systems (includingsolar), fuel-oil systems, oxygen systems also in non-flammable medical-gas systems. They are produced that Copper fluid is casting to the billet moulds and follows to the extrusion press, after annealed tubes are drawing, to be copper tubes. They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

The copper tubes manufactured by us are extensively used in AC & R (industry Air Conditioning and Refrigeration). Applications Of Copper Tube : • Water distribution systems • Chilled water mains • Drainage and vent systems • Heating systems(includingsolar) • Fuel-oil systems • Oxygen systems • Non-flammable medical-gas systems etc. Some of the reasons for using copper in mechanical tube systems are: • Versatility • Easy to join and install • Wide range of sizes • Problem-free performance • Long lasting and maintenance free • Corrosion resistance • High thermal conductivity • An abundant resource They are produced that Copper fluid is casting to the billet moulds and follows to the extrusion press, after annealed tubes are drawing, to be copper tubes. They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

We offer a wide range of rods, which are used for electroplating, switchgear, ship building and power generating equipment, as they are high-conductivity. On the other hand, they are widely used as radiator in electrical product, as its high- thermal conduction. They are produced that copper fluid is casting to the billet moulds and follows to the extrusion press, after that annealed rods are drawn, to be copper rods, 2000 mm to 6000 mm length, 10 mm to 175 mm diameter and they are according with TSE 435, DIN EN 12163 and DIN EN 13601. General properties material with minimum copper content 99.95%

Request for a quote

REP INTERNATIONAL

France

TYC 22 Press The French company DubourgelGrange is renowned for the quality of its sanitary product range. The factory has fully automated "REP Tung Yu" machinery equipped with handling units and robots (loading and unloading), which operate in 3 shifts for the major part 7 days a week. These machines are used to produce highend toilet covers and seats made in thermoset resin (ureaformaldehyde).

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 4,000 kN. Platen size 750 x 800 x 80 mm. Injection volume 2,000 cm³ or 5,000 cm³. The H610 allows Automated productions. Injection molding (more or less simple parts). A small footprint and height. An optimized cycle time. etc.

Request for a quote

REP INTERNATIONAL

France

The TYC2RT compression press allows the production of rubber mouldings with compression moulding or vacuum compression. The twoplate in/out with 45° inclination of the upper plate is suitable for various options. They are particularly suitable for moulding Orings, pharmaceutical stoppers, syringe plungers, and many other rubber parts. They are available in 2RT or 3RT series depending on the number of plates in the mould. Equipped with a 4post clamping system with high precision parallelism, their adjustable opening stroke allows different mould heights. The vacuum bell system reduces the curing time, thus increasing productivity.

Request for a quote

REP INTERNATIONAL

France

Machine features Top Closing. Specific pressure 600 kg/cm². Safety light curtain, double hand control. Available in single and doubledeck versions.

Request for a quote

REP INTERNATIONAL

France

Machine features Specific pressure 500 kg/cm². Dimensions of the heating platens 1500 x 1500 mm. Minimum mould closing speed 0.03 mm/sec.

Request for a quote

REP INTERNATIONAL

France

Machine features Closing force 3,200 kN. Size of the platens 1,250 x 630 mm. Injection volume 1,000 cm³. Machine developed for largeseries injection molding involving parts with inserts, such as for example the injection molding of housing seals.

Request for a quote

REP INTERNATIONAL

France

The Microject is a micromachine of a clamping force of 60 tons designed for the injection molding and overmolding of inserts used in small parts. Usability and flexibility. Plug and Produce! Characteristics MICROJECT LSR Maximum injection volume 3.77 (at 2000 bar) or 6.94 (at 1500 bar) or 10.37 (at 1000 bar). Clamping force 60 kN. Mould dimensions 150 x 100 mm. Overall dimensions 1.2 x 0.75 m. Simplicity and flexibility Installation in 30 minutes. Mould setting time optimally reduced. Intuitive touch screen interface.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REP INTERNATIONAL

France

Type V510 Core 3,050kN G10 is the 10th generation of REP injection molding presses with two versions available, on the one hand the Lean range G10 Core and on the other hand the Performance range G10 Extended. The G10 Core is a machine line, which has been matched for less demanding processes. It features all major costoptimized functionalities and the expertise of REP.

Request for a quote

REP INTERNATIONAL

France

THP range machines are particularly appropriate for the molding of oil seals, backup rings, parts for the automotive industry and many other rubber parts. There are two series, 2RT or 3RT, depending on the number of mold platens. Of simple design for easy maintenance, they can be provided as single or double station machine. Their vacuum cover design allows for reduced curing time and therefore increased profitability. The top platen, which is inclined by 60°, is suitable for different demolding options.

Request for a quote

REP INTERNATIONAL

France

Type V510 Extended 3,050kN Machine features Clamping force 3,050 kN. Size of the platens 500 x 630 mm (630 x 630 mm optional). Injection volume 1,000 or 2,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions.

Request for a quote

REP INTERNATIONAL

France

Type V710 Extended 5,100kN Machine features Clamping force 5,100 kN. Size of the platens 630 x 800 mm (800 x 800 mm optional). Injection volume 2,000; 5 000; 8,500 or 11,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,950 kN. Size of the platens 450 x 450 mm. Injection volume 1,000 cm³. The H49 is designed for Automated production. Injection molding (more or less simple parts). Low floor space and height requirement. An optimized cycle time. etc

Request for a quote

REP INTERNATIONAL

France

Electric horizontal machine, ultra compact for an optimized productivity! Suitable for the injection of many elastomers (rubber, silicones, etc.) Compact & ergonomic 33% smaller footprint compared to other presses on the market All features and production capacity in less than 4 meters length Productive & electric powered performance Productivity +20% 60% reduction in injection time 30% decrease in cure time Sustainable & Ecofriendly 50% power consumption 100% Water consumption 14% Waste reduction Oil free The “SmartWire” technology allows production to become autonomous and connected.

Request for a quote

REP INTERNATIONAL

France

Economic injection molding presses. A REP injection unit combined with a closing unit of a Tung Yu press. This combined technology offers openended options Separate extrusion and injection thanks to the "Y" type injection unit. 2 or 3stroke closing unit. Proportional closedloop temperature control. Optimized floor space and ergonomics thanks to its modular design.

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

REP designs and manufactures injection moulding presses optimized for special applications, with one of them being the molding of bladders (open or closed) for the production of tyres. Clamping force from 8,000 to 22,000 kN. https//www.youtube.com/watch?v=7EOOJ7wB_us

Request for a quote

SHORE AUTO RUBBER EXPORTS PVT. LTD.

India

We offer a range of moulded parts – Orings, Seals, Washers, Gaskets, Mountings, Grommets, Vibration Isolators, etc, in a range of materials including, EPDM, PVC/NBR Chloroprene, Polyacrylic, Vamac, NBR, HNBR, XNBR, Hypalon, Fluorosilicone, Silicone and FKM. Transfer, Injection and Compression Moulding Presses Available Standard Size available off the shelf with our global

Request for a quote

FATRA A.S.

Czech Rep.

NOVOPLAST – plasticized PVC The title NOVOPLAST ® indicates plasticized PVC granulates. It is a mixture of various additives combined suitably according to its further use. The most important additives to plasticized mixtures may in addition to PVC and plasticizers include thermal stabilisers, lubricants, separation agents, filling agents, pigments, flame retardants, light stabilisers, antioxidants, various modifiers, etc. The content of plasticizer in the mixture is determined by final hardness of the mixture. Hardness of resulting mixtures ranges from 45 degrees on the Shore A scale to the hardest Novoplast – 60 degrees on the Shore D scale. Novoplast granulates are processed subsequently using mainly extrusion, injection moulding, and mould pressing technologies. Final products manufactured from plasticized NOVOPLAST® granulates are various types of hoses, hoses with special resistance against gasoline, diesel, oil, frost, etc., technical mouldings, floor covers, outsoles,...

Request for a quote

REP INTERNATIONAL

France

Type V410 Core 1,600kN G10 is the 10th generation of REP injection molding presses with two versions available, on the one hand the Lean range G10 Core and on the other hand the Performance range G10 Extended. The G10 Core is a machine line, which has been matched for less demanding processes. It features all major costoptimized functionalities and the expertise of REP.

Request for a quoteResults for

Moulds for presses - Import exportNumber of results

41 ProductsCountries

Company type

Category

- Copper and copper alloys (3)

- Anti-vibration supports (1)

- Copper sheets and bands (1)

- Copper wires and cables (1)

- Driveshafts and micro-motors - electric (1)

- Finished Metal Products (1)

- Foundries - copper, bronze and brass (1)

- Glass manufacturing - machinery and equipment (1)

- Hydraulic equipment (1)

- Magnets (1)

- Metal detectors (1)

- Metallurgy - machinery and installations (1)

- Presses, hydraulic (1)

- Rubber products (1)

- Studs and bolts, fastening (1)

- Water plants (1)