- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moulding rubber articles

Results for

Moulding rubber articles - Import export

LAUSITZ ELASTE GMBH

Germany

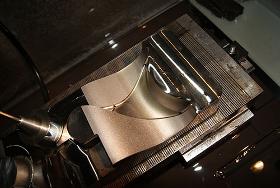

We produce precise moulded rubber articles on machines with a maximum clamping area of up to 1,500 x 2,000 mm.

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Since 1934 working with elastomers, we have developed special know-how in development and manufacturing in the field of technical hose products. Hoses Hose systems Moulded articles Rubber-metal bonds Expansion joints Special Versions As individual components or as combinations. Here, our experts unleash their creative powers and problem-solving skills. The main features of these customer-specific versions are top quality and high degrees of innovation and individualisation, directly maximizing the benefits to the customer. The following pages give some insight into the wide range of technical hose products and possible solutions to problems. Please do not hesitate to contact our technical sales department for more information.

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using the technologies of injection molding: - Technical articles - Caps - Various plastic elements Our products have numerous applications in multiple areas of production such as: home appliances, automotive, electronics, cosmetics, detergents, etc. In the creation of injection-molded articles we use a wide variety of plastic materials: ABS, PA, PC, PS, POM, TPV, TPE, PP, PE, as well as reinforced plastics (glass or mineral filled) . All materials are sourced from established and reliable suppliers from Germany, Italy, Bulgaria and Great Britain. The size of our injection-molded articles can weigh up to 1000gr with a clamping force of the machine from 50 to 200 tons.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

REP INTERNATIONAL

France

The V310 is available as standard with a Y400 or Y1000 injection unit. It is distinguished by its very small footprint Machine features: - Clamping force: 1,100 kN. - Platen size: 335 x 400 mm. - Injection volume: 400 or 1000 cm³.

Request for a quote

REP INTERNATIONAL

France

In order to be able to offer other alternatives, the REP offer is being expanded with localized, high-performance and economical solutions. Manufactured in China and India, our G9A and URP ranges are specially designed for the Asian market. The G9A range consists of : - V49A Clamping force 1600 kN. Size of the platens 430 x 510 mm. Injection volume 1000 cm³. - V59A Clamping force 2600 kN. Size of the platens 500 x 630 mm. Injection volume 1000 or 2000 or 5000 cm3 - S59A Clamping force 3000 kN. Size of the platens 560 x 780 mm. Injection volume 1000 or 2000 or 5000 cm3 - S709A -Clamping force 5100 kN. Size of the platens 630 x 800 mm. Injection volume 2000 or 5000 or 8500 or 11000 cm3

Request for a quote

REP INTERNATIONAL

France

Part of our entry-level range, G9A machines combine REP's expert know-how and Indian skills

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 500 kN. Size of the platens 300 x 300 mm. Injection volume 125 cm³.

Request for a quote

REP INTERNATIONAL

France

V79 : a model with innovative ergonomics : no pit for the press, no platform for the operator. This customized V79 is used for large volume bi-material injection with automatic loading and demolding.

Request for a quote

PHILPLAST LTD.

Bulgaria

Our tooling engineers and designers have extensive experience in creating various blow molds and injection molds. Our in-house tooling department produces molds for most plastic articles made in Philplast as well as molds for use outside our company. We can design, produce and issue technical documentation before the mold making, or we can make molds from 3D documentation provided by the client. In our tooling production we use new fully equipped high-performance CNC machines. The maximum size of our blow molds is for articles up to 20 liters in volume. The maximum dimensions for our injection molds are 546 x 896mm with a maximum weight of 2,500kg. All molds made to be used in Philplast are thoroughly tested on out machines to ensure their perfect quality.

Request for a quote

VLADIMIR PLANT OF RUBBER TECHNICAL INDUSTRY (VLADRTI LLC)

Russia

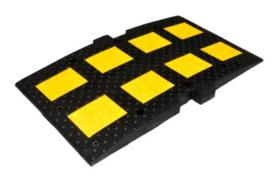

Rubber speed bump is a product manufactured by our company for many years. As a manufacturer, we understand the full degree of responsibility, and offer balanced and thoughtful solutions to ensure road safety. Thanks to many years of experience, we have managed to develop a high-quality product with high performance properties. Our products are made from a wear-resistant rubber compound used in the tire industry, which guarantees a long service life. Leading companies in the field of road maintenance and improvement trust the quality of our products. IDN-900 - end - this is the largest type of elements in the line of artificial road bumps. It provides the safest passage for vehicles by creating a long and smooth artificial roughness on the road surface. Has 12 holes reinforced with washers. Anchor bolts with a diameter of 10 mm are used for fastening. Holes for bolts with a diameter of 11 mm.

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

We have proven experience in (seamless) injection molding, both on natural as synthetic rubber types. Tooling design is also done in-house.

Request for a quote

PET TECHNOLOGIES

Austria

Universal semiautomatic blow molding machine for PET bottles 0.2 – 10.0l with output 800 bph. Easy to adjust and maintain. Technical data Output 600-800 bph with volume of 5-6 l 250-350 bph with volume of 7-10 l Neck diameter28-48 mm Bottle volume0,2-10,0 l Blowing pressure8-10 bar Low pressure15(up to 25) bar Low and high pressure air demand0,8m³/min for bottle 1.5 l Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 23 kW Overall dimensions1425х800х2300mm 1700х600х1720mm Weight 700+225 kg

Request for a quote

PET TECHNOLOGIES

Austria

Automatic blow molding machine for PET bottles with volume 3.0-10.0l and output 2 500 bph. Separate block of valves for each mold cavity designed by PET Technologies R&D. CE certificate and conformity to HACCP. Technical data Output2 500 bph with volume of 3-8 l up to 1 800 bph with volume of 10 l Bottle volume3,0 – 10,0 l Blowing pressure8-10 bar Low pressureup to 40 bar Low and high pressure air demand10,0 m³/min Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 68 kW Overall dimensions8200 х 3400 х 2600 mm Weight~ 6 800 kg (*preform 66-85 gramms)

Request for a quote

PET TECHNOLOGIES

Austria

Automatic blow molding machine for PET bottles with volume 0.2-2.0l and output 3 000 bph. Patented mold closing system: 1500 bph from one mold cavity. CE certificate and conformity to HACCP. Technical data Output up to 3 000 bph Bottle volume 0,2 – 2,0 l Blowing pressure 8-10 bar Low pressureup to 40 bar Low and high pressure air demand1,3 m³/min for bottle 1.5 l Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 41 kW Overall dimensions6400 х 2800 х 2300 mm Weight ~ 2 350 kg (*1,5 liter with 30-35 gr. PCO-Preform)

Request for a quote

PET TECHNOLOGIES

Austria

Automatic blow molding machine for PET bottles with volume 3.0-10.0l and output 1 600 bph. Two independent blowing units to produce 2 bottle formats by turns. CE certificate and conformity to HACCP. Technical data Output1 600 bph with volume of 3-8 l up to 1 200 bph with volume of 10 l Bottle volume3,0 – 10,0 l Blowing pressure 8-10 bar Low pressureup to 30 bar Low and high pressure air demand5,0m³/min Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 46 kW Overall dimensions7400 х 3200 х 2720 mm Weight ~ 4 600 kg (*preform 67-85 gramms)

Request for a quote

OBRT HARI-PLAST

Bosnia and Herzegovina

we have machines from 50 to 550 tons of closing force and blow moulding machine up to 2 liter. We can make injection moulded parts up to 1100 gr. We offer serviced production of injection molded and blown parts with quality and fast delivery. o Our company is located in Bosnia and Herzegovina. Proximity to European countries means low transport costs and short delivery times. Kontakt: info@hariplast.com

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Moulding rubber articles - Import exportNumber of results

17 ProductsCountries

Company type