- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- modules for electronics

Results for

Modules for electronics - Import export

KENDRION (VILLINGEN) GMBH

Germany

Thanks to extremely compact design the overexcitation rectifier "Slim Collection" can be installed in very restricted space. The module features a central bore for screw fixing inside the terminal box. It can also be installed by using an adhesive pad.

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

The B+B dew module is a universal, resistive evaluation electronics for detection of condensation for the dew sensors of the SHS series.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Equalize airflow pressure within speaker chambers Our POREX® porous flow modulators provide precise airflow control between speaker chambers and to the exterior of the unit, thereby reducing air pulses caused by speaker movement. Allowing a freestanding speaker system to breathe freely during temperature fluctuations, our flow modulators equalize pressure within the unit. Designed for precise airflow control, our flow modulators: Protect sensitive electronic and acoustic components–POREX® porous materials repel dust, water, sweat, oils and other liquids from entering the enclosure. Can be custom developed in three-dimensional shapes for increased design flexibility. request sample ask an engineer

Request for a quote

FRIGOFLUID S.R.L.

Italy

The PAD-V adiabatic system is the optimal solution for increasing the efficiency of air systems, with capacities from 75 to 1,100 kW. Dry operation during cold periods: ambient air is drawn in and conveyed to the heat exchange coils (where the fluid to be cooled passes through): no water in the circuit, as during standard dry cooler operations. Energy use is also optimized by electronically modulated fan speeds based on temperatures. Adiabatic operation during hotter periods: outside air passes through the humidifier pack to be pre-cooled, before being conveyed to the finned coils and performing its cooling function: efficiency is increased. This also makes it possible to work at lower ambient temperatures.

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter type DMP 333 has been especially designed for use in hydraulic applications with high static and dynamic pressure. The transmitter is characterized by an excellent long term stability, also under fast changing pressure as well as positive and negative pressure peaks. The modular concept of the device allows to combine different stainless steel sensors and electronic modules with a variety of electrical and mechanical versions.Thus a diversity of variations is created, meeting almost all requirements in hydraulic applications. Features: — nominal pressure: 0 ... 100 bar up to 0 ... 600 bar — accuracy:0.35 % (opt. 0.25 % / 0,1%) FSO — excellent long term stability, also with high dynamic pressure loads — insensitive to pressure peaks — high overpressure capability Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts — SIL 2 version according to IEC 61508 / IEC 61511

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter DMP 331 can be used in all industrial areas when the medium is compatible with stainless steel 1.4404 (316 L) or 1.4435 (316 L). Additional are different elastomer seals as well as a helium tested welded version available. The modulare concept of the device allows to combine different stainless steel sensors and electronic modules with a variety of electrical and mechanical versions.Thus a diversity of variations is created, meeting almost all requirements in industrial applications. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 60 bar — accuracy: 0.35 % (opt. 0.25 % / 0,1%) FSO — excellent thermal behavior — excellent accuracy — flush pressure port G 1/2" from 100 mbar Optional Features: — IS-version Ex ia = intrinsically safe for gases and dusts — SIL 2 according to IEC 61508 / IEC 61511 — pressure sensor welded — customer specific versions

Request for a quote

MAGTROL

Switzerland

Magtrol’s TS In-LineTorque Sensors provide extremely accurate torque and speed measurement. Each model has an integrated conditioning electronic module providing 0VDC to ±5VDC (±10VDC) torque output through an 8-pole connector, as well as a USB interface which can be directly connected to a computer. The sensor is delivered with software allowing easy connection and data acquisition. A speed encoder provides a minimum of 360PPR (Pulse Per Revolution) in Tach A, Tach B and Index reference Z (1PPR). Magtrol Torque Sensors are very reliable, providing high overload protection, excellent long-term stability and high noise immunity. TSSeries sensor models are strain gauge-based measuring systems with imbedded telemetry signal transmission. Three LED lights allow a visual check of the sensor status by color code. The sensor is powered by 24VDC (12-32VDC) through its connector. TARE & B.I.T.E. (Built-In Test Equipment) can be activated by either software or input from the 8-pole connector.

Request for a quote

MAGTROL

Switzerland

Magtrol offers three types of torque transducers for dynamic torque and speed measurement. All three transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits most notably that no electronic components rotate during operation. Each model has an integrated conditioning electronic module providing a 0 to ±10 VDC torque output and an open collector speed output. Magtrol’s Torque Transducers are very reliable, providing high overload protection, excellent long-term stability and high noise immunity.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The H250 M40 is the standard variable area (VA) flowmeter for the process and OEM industry. The VA meter combines mechanical flow measurement of liquids or gases with state-of-the-art communication capabilities. Additional electronic modules can be added or replaced at any time without process interruption. The H250 M40 is available in various materials and in many different versions. The sturdy all-metal flowmeter can be also used in applications with high pressures (up to 1000 barg / 14500 psig), temperatures (-196...+400°C / -320...+752°F) or aggressive media. It even allows installation in horizontal or fall pipes up to DN150 / 6". A special version for use in hygienic applications is also available. The H250 M40 is intrinsically safe and explosion-proof. Certain variants of the flowmeter with limit switch or analogue output are suitable for use in Safety Instrumented Systems (SIS).

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

Induction magnetometer allows to measure magnetic field isotherms of magnetization (magnetization versus magnetic field (M(H) dependences) in the fields up to 2 T and in the temperature interval from 80 to 370 K. Magnetization is measured by induction method. Specification: - temperature interval — from 80 to 370 К, - magnetic field interval — from 0,02 to 2 Т, - relative measurement accuracy of magnetization - 2 %, - maximal sample dimensions - Ø1.5 × 3.7 mm. Magnetometer (its measuring part) consists of the measuring insert, electronic module and control and data acquisition program and can be used together with the magnetocaloric measuring setup (which includes permanent magnet adjustable magnetic field source, liquid nitrogen cryostat, temperature controller, 2 digital voltmeters, control computer with corresponding interface and control boards).

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Allows the counter to be reset to zero manually at the push of a button or program controlled during marking. Option PN comprises of a compact compressed-air cylinder in the marking wheel and a RESET key on the machine’s control panel. Programmable, automatic reset function requires Option W. W - PROGRAMMABLE ELECTRONIC CONTROL MODULE FOR PN PNEUMATIC RESET SYSTEM OR OTHER PNEUMATICALLY OPERATED FUNCTIONS Causes, for instance, the counter to be reset to zero or the marking wheel to be lifted every time a preset length of cable has passed through the machine. An additional, programmable contact closure allows an external process (e.g., cutting the cable at a preset length after the counter has returned to zero) to be triggered. 2W - EXTERNAL DEVICE PRE-SELECTION Option 2W features a second pre-selection counter to be used for controlling an external device, e.g. for triggering a cutting device when achieving a pre-defined length of the marking good. The pre-defined length corresponds

Request for a quote

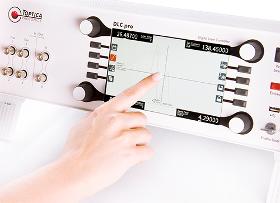

TOPTICA PHOTONICS AG

Germany

The DLC pro Lock is a software license that enables a number of features on a specific DLC pro. These allow to control the frequency of a laser for example by using a saturated absorption spectroscopy setup with a reference cell. This most popular example of frequency typically uses a modulation of the laser frequency, a de-modulation (Lock-In) for creation of the error signal and PID regulators for the generation of the error signal. All this may be achieved with a DLC pro control without further electronic modules.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Liquid FurnaceMeter™ is available for liquid flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the liquid type, inlet pressures, and scale ranges to provide precision process control for most applications. The Liquid FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The Liquid FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The Liquid...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for gas flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™ meets current NFPA86...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for either gas or liquid flow measurement. These meters can also be fitted with integrated manual flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YINGXINYUAN INT'L (GROUP) LIMITED

China

Power driver modules provide the physical containment for power components, usually IGBTs and MOSFETs in a half bridge or one-, two- or three-phase configurations. Power semiconductors or dies are soldered or sintered on a substrate that carries the power semiconductors and provides electrical and thermal contact and electrical insulation where needed. Power modules provide a higher power density and are in many cases more reliable and easier to cool.

Request for a quote

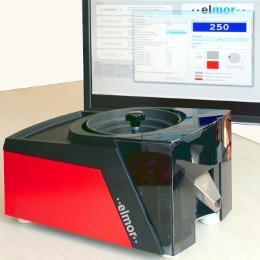

ELMOR

Switzerland

The PC controlled, high sensitive elmor C3 Seed counter is preferably used in scientific counting tasks in laboratories Universities, research and breeding projects or in seed quality control etc. Parts that can be processed with the C3 seed counter are, for example: Dust fine plant seeds such as Arabidopsis thaliana or Begonia semperflorens Vegetable seeds, grains or seeds of ornamental plants Insects, pupae and eggs Small mechanical parts Pharmaceuticals Semiconductor chips etc. The C3 Counter is controlled solely via PC. Thus new solutions for the ever growing demands of the customers are possible. All settings and the results of all operations are logged and saved . This is an essential prerequisite for quality control and traceability of test results. The parts that can be counted with the C3 seed counter can be extremely small and irregularly shaped. Thus they are very difficult to handle manually. Dosing these parts with scales is often flawed or impossible. Therefore the use of the of C3 opens new options, since e.g. smallest parts in the sub-milligram range can be dosed faster and more accurately by counting than weighing the pieces. With additional software modules also further evaluations can be performed. These are currently: direct 1000 grain weight determination and the grain size analysis. Technical data Counts Parts from 0.1 to 18mm in diameter For spheres of 2mm diameter: Counting rate: 50’000 parts per hour Typical counting error: less than 1/1000 Runs under Windows XP/7/8.1 Free Serial Port (RS232) or USB needed Software included Totalizer Preset Counter Additional software available: Direct determination of the 1000 Kernel Weight Analysis of the size of the counted particles: Particle Size Analysis Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Automatic 1000 Grain Weight Measurement By means of an additional software module, an electronic balance and a special frame, the precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 500 or 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without no arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. But most important is that in this procedure the particle size selection is impossible. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Particle Size Analyzer The precision seed counter C3 can be used as particle size analyzer to determine the particle size distribution of a given sample by means of a special software module. The size of the singularised and free falling parts is measured in one dimension with a resolution of some 1/100 mm. This measurement is intended primarily to compare different samples qualitatively. With spherical parts the measurements give also quantitative information. The measured values of the particle size analyzer are stored as txt file. This makes it possible to further process the raw data individually by means of appropriate standard software. Filling Carousel The C3 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of our counting machines C1, C3 or CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity Click here to add your own text Click here to add your own text

Request for a quote

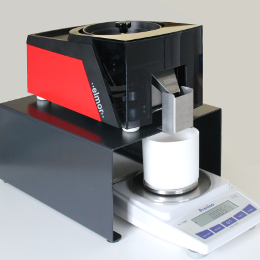

ELMOR

Switzerland

With seed tests the 1000 kernel weight is an important quality criterion, which must be determined with high accuracy. Counting and dosage of mechanical and electronic small articles as SMD’s are made increasingly also over the determination of the 1000 grain weight. By means of an additional software module, an electronic balance and a special frame, our precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Technical data Scales are available with a resolution of 1 mg, 10 mg or 100 mg. The data of the elmor C3 seed counter and the scale are sent to the control computer via two RS232 ports or – on request – with two USB cables.

Request for a quote

GLOBECORE

Ukraine

The unit is designed to measure the dielectric strength of transformer oil and other dielectric fluids according to IEC 60156, ASTM D877, ASTM D1816. It is a fully automatic device - allows testing according to the procedures defined in these standards, as well as according to the user procedures specified in the appropriate section of the setup menu. The core of the unit is the high voltage transformer and electronic modules. The unit operates by gradually increasing the voltage on the secondary winding of the high voltage transformer from zero to the maximum voltage, or to the voltage at which an electric breakthrough occurs in the dielectric fluid in the measuring cell installed on the high voltage contacts of the transformer. During operation, AC (50-60Hz) voltage is supplied from the secondary winding terminals through the cell electrodes into the dielectric fluid in the measuring cell.

Request for a quote

DK CERAMIC CIRCUITS

Belgium

LTCC (Low Temperature Co-fired Ceramic) is a multilayer capable substrate technology offering excellent RF and microwave performance characteristics. Thanks to its low sintering temperature (around 900°C) allows it to co-fire with highly conductive metals such as silver and gold. It is sometimes referred to as “glass ceramics” because glass is mixed in its main raw material, alumina. Elite Advanced Technologies is one of the few LTCC specialists globally that is producing its own green tape (base material low temperature co-fired ceramics). LTCC is best suited for applications that can take advantage of one or more of the following: Good electrical performance Dimensional and electrical stability under temperature, moisture and mechanical stress 3D capability curved, cavities, channels Effective thermal management with metal loaded vias (>100 W/MK) Hermeticity Matched TCE with semiconductors (Thermal Coefficient of Expansion) Multiple assembly and packaging solutions

Request for a quoteResults for

Modules for electronics - Import exportNumber of results

23 ProductsCountries

Category

- Electronic components (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Sensors (2)

- Dry cooling towers (1)

- Electric transformers, converters and rectifiers (1)

- Electromagnetic compatibility measuring equipment (1)

- Electronics - import-export (1)

- Flowmeters (1)

- Printed circuits (1)

- Supply meters (1)

- Testing equipment (1)