- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- modern welding

Results for

Modern welding - Import export

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

For temporary buffering due to fluctuations in gas production or inoperable production systems or consumers, a storage of the produced biogas is required. ennox has developed the NOXstore gas holding system for the zero pressure or fluctuating pressure storage of biogas from the digester. The storage of the biogas/sewage gas is made in a cylindrical gas bag which is freely hung in a building or silo. The silo serves in this case as an effective supporting and protective construction. The storage systems are designed according to the latest governing international standards and regulations i.e., DWGW, WAV, DWA, SUWA, safety regulations for biogas systems. The gas bag is manufactured from a high quality polyester membrane (non-flammable, fungus repellant and methane/UV resistant) utilizing the most modern frequency welding techniques. ennox offers not only the design, construction and installation of the gas storage system, but also the subsequent ongoing inspection and...

ESTIMET SP Z O.O.

Poland

Our company specializes in a wide range of welding services, with an emphasis on high quality welding welds. We use modern technologies that guarantee excellent results. We carry out welding of a variety of materials, including carbon/structural steel, stainless steel and aluminum. Our production facility meets stringent quality standards, such as PN-EN ISO 3834-2:2007 and PN-EN 1090-2:2018-09. We have implemented modern welding technology for group 1.1 and 1.2 carbon steels in accordance with PN-EN ISO 15614-1:2017-08. Our skills include working with steels such as S355J2 and steels with lower yield strengths, especially for material thicknesses above 3 mm for fillet welds (3-23 for butt welds), welded using the MAG-135 method. We provide professional execution of any steel welding service.

Request for a quote

COMPANY TOR

Russia

ТОРУС-200 is a modern welding inverter device based on a digital high-frequency mains voltage transducer. The device is designed for electric arc welding of low-carbon, alloy and stainless steels, it can operate in TIG and MMA modes. Obtaining high-quality welding joints does not require high qualifications from the employee, which is important for novice welders. In short-circuit mode, the device almost does not consume current, which allows it to be powered from petrol power units with a capacity of 4 kW (6 kVA) and a household network with slumps up to 165 V. ТОРУС-200, like other inverter welding machines of the ТОРУС line, allows you to get welding with stable parameters. It is characterized by: small weight – 5 kg, high performance factor and the ability to work with electrodes with a thickness from 1.6 to 5 millimeters. In addition, the ТОРУС-200 welding inverter is designed for continuous operation not only indoors, but also outdoors.

Request for a quote

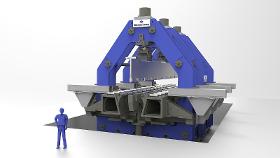

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

RUHFUS SYSTEMHYDRAULIK GMBH I.L.

Germany

Contract Manufacture We also make our machining facilities available to businesses that just want to outsource specific production processes. Here we focus on being used in the field of deep drilling, peeling and rolling, and in honing. We are also happy to make our capacity available in the field of machining, welding and blasting and painting. In particular by the extension of our machining capacity by several CNC-controlled 4-axle turning centres with driven tools, a modern welding plant for tubes up to 16,000 (18,000) mm length and an efficient paint shop, further capacities have been created here.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Modern welding - Import exportNumber of results

5 ProductsCountries

Company type