- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixed media

Results for

Mixed media - Import export

WIWOX GMBH SURFACE SYSTEMS

Germany

Mixed alumina type WIWOX® RK has a low ferrite content and is particularly suitable for applications where a high consumption of blasting abrasives cannot be avoided. Mixed Alumina is produced from ceramic grinding wheels and reclaimed alumina dust from the blasting and grinding industry. It consists of a mixture of white, pink and brown alumina, and is an iron-free alternative for many sectors of the blasting and grinding industry.

Request for a quote

FLUX-GERÄTE GMBH

Germany

The Drum pump F 426 is ideal for mixing and/or pumping inhomogeneous media. You can keep media moving that tend to segregate, even during pumping. With the outlet closed, e.g. via a hand nozzle, the F 426 can be temporarily operated as pure mixing pump. By turning the adjusting lever, the pump can be easily adjusted to "mixing" or "pumping". The pump is easy to dismantle for rapid cleaning. The pump is available in stainless steel and polypropylene. The stainless steel version can also be used in hazardous areas. Benefits: - 3 operating modes in one pump: Conveying Conveying with simultaneous mixing Temporarily mixed operation - Switching operating modes is possible even while operating - Easy to dismantle for cleaning - Two control levers to easily open/close the mixing openings - Mixing openings allow backflow of medium for mixing back into the container - Distinct feature, only at FLUX: The inner tube is reinforced with a metal core on the PP model.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRP - Pneumatic agitator GRP – pneumatic agitator The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. ((Infotexte)) Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0. The GRP is a pneumatic agitator...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

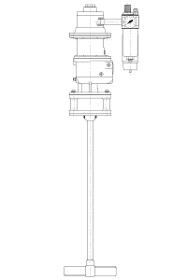

The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the GLP on a drum.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KELVION HOLDING GMBH

Germany

Double tube safety heat exchangers play an important role in applications where preventing media mixing in the event of a leak is paramount. They are widely used and accepted as standard in the chemical industry, power, heavy and light industry, oil & gas, marine, transportation, refrigeration and food & beverage sectors. Kelvion has a long track record in developing ground-breaking technologies always aiming to reach the highest levels of safety, environmental protection and cost-efficient operation. Our expert engineers are fully trained to provide you with the best-in-class solutions tailored to your specific requirements. As industries face ever stricter regulations for safeguarding requirements of environment and water supply, double tube safety heat exchangers are the technology of choice.

Request for a quote

EM-TECHNIK GMBH

Germany

The manually operated 6Z multiport ball valve consists of two multi-port ball valves that are compactly arranged one on top of the other in a housing with two levels. There is no flow connection between the individual levels. With one switching process both media flows are synchronously distributed or collected using a common shaft. Unintentional mixing of the media flows is not possible.

Request for a quote

EM-TECHNIK GMBH

Germany

The 7G injectors are pumps for pumping and mixing various media. The basic principle is simple: a gaseous media is used for the actuator; this media escapes at high pressure and high speed from a nozzle. During this process the media from the surrounding area is also drawn along and can be supplied to the downstream production process. Due to their design, the injectors do not need moving parts, as a result they have very low wear and are robust.

Request for a quote

EM-TECHNIK GMBH

Germany

The 6X multiport ball valve with pneumatic part-turn actuator (STANDARD) consists of two multi-way ball valves in a compact design arranged one on top of the other in a housing with two levels. There is no flow connection between the individual levels. With one switching process both media flows are synchronously distributed or collected using a common shaft. Unintentional mixing of the media flows is not possible.

Request for a quoteResults for

Mixed media - Import exportNumber of results

10 ProductsCountries

Company type