- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling machine – metal machining

Results for

Milling machine – metal machining - Import export

EMSIL TECHTRANS SRL

Romania

Robust and versatile milling machines

Request for a quote

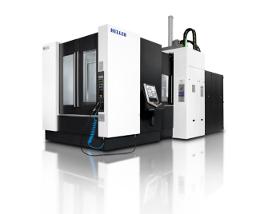

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The perfect 4-axis machining centre must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER H-series 4-axis machining centres. Components that have been reliably used in mass production for years coupled with a high dynamic guarantee you robust processes – even at their limits, seven days a week in 3-shift operations.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Designed for Production: The new generation of 5-axis machining centres F sets a new benchmark for cutting performance and precision With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

APD MAQMASTER

Spain

Cutting angles 30º / 150º Disc diameter 550 mm 13 fan-cooled spindle motors 1 x Triple Arm Aperture Motor 1 disc motor Independent 8-axis and 14-axis working units Mechanized Automatic feeding table for 10 profiles

Request for a quote

BOHEMIA METAL PARTS

Czech Rep.

Machining of metal products on a three-axis or five-axis CNC machine. Drill holes. Tapping a thread. Finishing of the metal by eloxatie, galvanizing, powder coating or printing is possible. For machining of stainless steel, steel, aluminum or hard plastics.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Part type: CNC milling and CNC turning compoents Material: Al 6061-T6 Surface treatment: red, gold, silver, gun, cinerous, black anodizing tolerance: ±0.02 application: guita frame

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: stainless steel/ aluminum 2.Machining type: precision cnc milling 3.Surface:Polishing ,Ra0.8 4.Tolerance:+/-0.1mm 5.Application : Medical/electric 6.Quality,reliability and long product life.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material: aluminum alloy Surface treatment: machining surface Tolerence: IT7 Machining method: 5-axis cnc milling and drilling Usage: biochem element

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"With the help of our rich machine park and well-experienced engineers, we can answer your custom design machine part needs. Please don't hesitate to ask for the price."

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

Request for a quote

STEEC

France

STEEC is able to carry out milling and micro-milling operations on complex mechanical parts with increasingly finer dimensions and increasingly tighter tolerances. STEEC carries out micro-drilling operations to manufacture not only parts but also very high precision electrodes. That enable all spark erosion micro-drilling and countersinking operations to be performed. Equipped with a stock of high-tech machines and leading edge IT tools, such as the Solidworks software, STEEC is capable of meeting special requirements and providing innovative solutions for each of its customers. The experience gained in other high precision machining technologies has enabled STEEC to develop innovative milling processes that are well recognized in the industrial environment.

Request for a quote

EC PLAZA

South Korea

MIRHO Corporation make an industrial CNC in person in Korea, called G-Aid, also using for education , industry, dental purpose. We are introducing our signature product, Smart Milling Machine G AiD. G AiD is high speed milling machine for more precise machining. It has comparable six features with another CNC. - Control axis : simultaneous 4 Axis - Spindle : Max 30,000RPM 3.6kW - ATC : Tool detect sensor 7ea, Ф6 - Material : Titanium, Industrial Ceramic, Aluminum, Sus, Steel, SiC, Carbon, ALN, Etc. - Motor : AC servo with IP67 absolute system - Working Area : 100*100 mm - Power Requirement : CE, KCs - Weight : 336kg - External Dimensions : 600*780*1800 mm Feature 1 is "Multiple Jig Solution". Features 2 is "Optimized Motion Controller". Features 3 is "Easier User Interface". Features 4 is "High Speed Milling". Features 5 is Automatic Tool Length Measurement". Features 6 is " Optimized Footprint and Low-Cost High Efficiency".

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2020 CNC control : HEIDENHAIN TNC 640 Number of simultaneous axes : 5 Stroke X axis : 650 mm Stroke Y axis : 850 mm Stroke Z axis : 500 mm Traversing feeds X, Y and Z axes : 36000 mm/min X axis ball screw, Ø x pitch : 40 x 12 mm Y axis ball screw, Ø x pitch : 40 x 12 mm Z axis ball screw, Ø x pitch : 40 x 12 mm Angular A axis stroke : +/- 120 ° Angular C axis stroke : 360 ° Min. distance spindle nose / table : 150 mm Max. distance spindle nose / table : 650 mm Spindle type : HSK-A 63 Max. spindle speed : 20000 rpm Tool changer magazin number of stations : 60 Max. tool length : 300 mm Max. weight of single tool : 8 Kg Total max. weight in tool changer magazine : 480 Kg Max. tool diameter : 125 mm Total power required : 60 kVA Number of hours under power : 5683 h Number of running hours : 3183 h Machine weight : 12000 Kg Machine dimensions : 3390 x 3940 x 2970 mm With equipment

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC punching: sheet up to 4mm 1250x3000 mm; - CNC bending up to 3000 mm 100T; - Sheet rolling up to 4 mm, width 1500 mm; - CNC milling with 3-axle by vertical machining centres of up to 2000x500x600 mm; - CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm; - CNC turning, rod up to D65 mm; - CNC turning by vertical machine up to D250, L160; - Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000; - Flat grinding: 200x500mm.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC punching: sheet up to 4mm 1250x3000 mm; - CNC bending up to 3000 mm 100T; - Sheet rolling up to 4 mm, width 1500 mm; - CNC milling with 3-axle by vertical machining centres of up to 2000x500x600 mm; - CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm; - CNC turning, rod up to D65 mm; - CNC turning by vertical machine up to D250, L160; - Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000; - Flat grinding: 200x500mm; - External thread rolling: M8, M10, M12, W16.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our lathes machines are: PRAISE TT60-20L-C1 ¤ 600 x 2000; BLOHM ORBIT 300 x 600; STUDER FAVORIT ¤ 350 x 650; ACRA ASG2880 HSR 750 x 2000. The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our lathes machines are: DOOSAN PUMA ¤ 600/¤ 900 x 2500; DOOSAN LYNX300M ¤ 370 x 720; ALPHA 1400X3 ¤ 400 x 1400; DMG MORI NLX 2500/1250 ¤ 400 x 1250 The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our milling machines are: DOOSAN DCM3250F 5200 x 3250 x 2700; DOOSAN ACE-DB250 4000 x 2000 x 2000; DOOSAN VM960L 2500 x 960 x 800; DOOSAN MYNX540 1020 x 540 x 530; DOOSAN DNM750 1630 x 760 x 650; HARTFORD HSA-5320VF 5050 x 2100 x 1150, XYZ 1510 1500 x 600 x 600; MORI SEIKI NV5000 800 x 510 x 510; OKK VC-X5005AX 700 x 850 x 610 The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High precision steel shaft/splined shaft for connecting/coupling shafts 1) Customer’s drawing or samples accepted. 2) Excellent and high quality control. 3) Prompt delivery. 4) Competitive price. steel shafts 1) Material: Carbon steel , Stainless steel,brass or as per customer’s requirements. 2) Diameter: 0.3-80mm, tolerance:+/-0.005mm. 3) Roundness: 0.003mm. 4) Roughness: Ra0.04. 5) Straightness: 0.005mm. 6) Hardness: HRC/HV. 7) Precision: Grade 6. 8) Length: Max.700mm. 9) Heat treatment:Point hardening,quenching hardening. 10) Surface treatment: zinc plating, nigrescence,chrome plating, nickel plating etc. 11) OEM Service: Providing us the drawing with detail information. 12) Offering products with speciality, quality and efficiency. 13)Package:Plastic bag inside and outer standard carton , pallet.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Metal Shaft Motor shaft, Fan shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part. Mechanical precision part/Mechanical precision part. 1) Material: Carbon steel, Stainless steel, brass or as per customer’s requirements. 2) Roundness: 0.001mm 3) Roughness: Ra0.04 4) Straightness: 0.001mm 5) Length: Max. 1000mm 6) Heat treatment: Point hardening, quenching hardening 7) Surface treatment: Zinc plating, nigrescence, chrome plating, nickel plating etc. 8) OEM Service: Providing us the drawing with detail information. 9) Offering products with speciality, quality and efficiency. 10) Package: Plastic bag inside and outer standard carton, pallet. According to client’s demand. Specifications for CNC METAL SHAFT

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs. The products are shown here ony to present the

Request for a quote

VIRMER

Netherlands

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quoteResults for

Milling machine – metal machining - Import exportNumber of results

66 ProductsCountries

Company type

Category

- Milling - machine tools (36)

- Machine tools - metal machining (25)

- Machine tools, metal machining - parts and accessories (17)

- Milling - steels and metals (3)

- Metals - Machines & Equipment (2)

- Punching machine tools (2)

- Mechanical transmission - components (1)

- Milling - woodworking machinery (1)

- Pharmaceutical industry - machinery and equipment (1)

- Steels and metals - machining (1)

- Testing equipment (1)

- Woodworking - machinery and equipment (1)