- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal-cutting manufacturing

Results for

Metal-cutting manufacturing - Import export

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The material is aluminum/stainless steel. The process is CNC laser cutting and bending. The finish is sandblasting and anodizing.

Request for a quote

SC PROFINOX SRL

Romania

We provide laser cutting services for stainless steel or aluminium sheets and pipes. High precision and fast execution are ensured by high-performance equipment and the experience of the Profinox team! Our laser cutting services have a number of benefits: Versatility – the tool can be used for a wide range of materials, with Profinox providing laser cutting services for stainless steel, aluminium or copper sheets and pipes; The power used for the laser metal cutting process is lower; The laser cutting procedure involves minimal deformation; Low costs for laser cutting; No contact between the part and the tool; Enhanced surface quality; Minimal burrs: this advantage provided by the laser metal cutting process also eliminates the need for further machining; Possibility to create and obtain complex shapes. Furthermore, the laser cutting process is silent and fast, ensuring a high precision of +/- 0.1 mm. If you have materials exceeding the maximum

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 0,90 kg Height : 12 cm Width : 99,1 cm Material: 2 mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 28,71 kg Height : 198 cm Width : 99 cm Material: 3 mm

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers product solutions for materials such as steel, stainless steel, nonferrous metals, grey and spheroidal cast iron, construction materials, and stone. We provide cut-off wheels, diamond saw blades, and machines for the construction and metalworking industries. Our cut-off wheels for steel, stainless steel, nonferrous metals, stone, cast iron, and construction materials offer top-notch properties. Designed specifically for steel and stainless steel, these thin and fine-grained wheels enable short cutting times and fatigue-free work, ensuring long life and preventing material damage. Our cut-off wheels for ring saws and cut-off machines deliver excellent performance and durability. We offer diamond saw blades and resin-bonded cut-off wheels in diameters of 300, 350, and 400 mm for petrol and electric machines. Hand-held ring saws are equipped with diamond tools ranging from 300 to 500 mm in diameter.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our stationary cutting tools offer high quality and a broad range, including lab cut-off wheels, resin-bonded wheels for steel and stainless steel, diamond wheels for cast materials, and high-performance CBN and diamond wheels for tungsten carbides and HSS. Years of innovation have advanced stationary cutting. Tyrolit cut-off wheels are durable and easy to use due to collaboration with manufacturers and customers. We guarantee sustainable solutions, offering cut-off wheels for various applications and custom products. For machining steel, stainless steel, nonferrous metals, and stone, our resin-bonded cut-off wheels are ideal, providing low lateral friction and preventing discoloration. Premium lab cut-off wheels ensure fast, deformation-free sample cutting. Diamond saw blades for cast iron are preferred for their longer lifespan, reduced dust, and increased safety.

Request for a quote

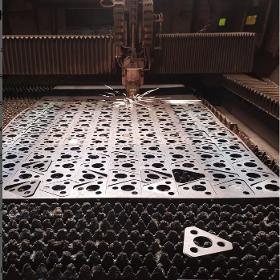

ESTIMET SP Z O.O.

Poland

Our services include water sheet metal cutting. The parts we cut comply with the EN 1090 standard, and therefore with the CE mark. We use the waterjet cutting method for various types of parts whose dimensions do not exceed 2000 x 4000 m and whose thickness is up to 200 mm. We cut with a stream of water with an admixture of abrasive at a pressure of 60,000 PSI, without introducing heat into the material, so we can cut in addition to steel materials: - stone - marble - plastic - rubber - glass The WaterJet method, or waterjet sheet metal cutting, involves the use of a jet of water at very high pressure - often supplemented by the addition of an abrasive. The jet is directed at the surface to be processed, which makes it possible to cut a shape in it with the desired dimensions. Modern WaterJet technology is an attractive alternative to plasma or laser cutting.

Request for a quote

ESTIMET SP Z O.O.

Poland

One of the areas of ESTIMET's offer is laser cutting, used for precision processing of sheet metal, pipes and profiles. In ESTIMET's machine park we have two fiber lasers of 6 kW and 8 kW. Thanks to these devices, we can precisely cut elements with maximum dimensions of 2000 x 4000 mm. Our laser cutting services comply with the EN 1090 standard, as confirmed by the CE mark. We are ready to take on even the most demanding orders, offering to cut sheet metal made of a variety of materials, such as carbon steel, stainless steel, aluminum, copper or bronze. We also have a gas burning machine, dedicated to metal sheets up to 150 mm thick. In addition, we have specialized machines for cutting pipes, profiles and sections with maximum dimensions of 450 x 450 mm. We can cut tubes and profiles in straight sections as well as at an angle. The range: steel: 0,5 - 25 mm INOX: 0,5 - 30 mm aluminum: 0,5 - 25 mm brass: 0.5 - 10 mm copper: 0.5 - 10 mm galvanized: 0.5 - 4 mm

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

ILK IHRACAT AS.

Turkey

Up to 70 mm! We offer laser precision from 0.5 mm to 70 mm. Experienced Team: Expert and experienced laser cutting operators. Advanced Technology: We guarantee cutting quality and precision using the latest laser cutting technologies. Custom Solutions: We offer customized cutting solutions that fit customer needs. Fast Delivery: We support your production processes with timely and swift deliveries. Get a Quote Now Contact us immediately for the most suitable laser cutting solutions for your needs. Our professional team is ready to provide you with exclusive offers. Steeling.Net carries out partner export activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

ILK IHRACAT AS.

Turkey

Shape Your Project with Precision Plasma Cutting Service In industrial design and manufacturing projects, accurate cutting is a cornerstone of success. This is where our plasma cutting service comes into play, offering the ability to shape materials like metal, aluminum, steel, and more with precision. Get a Quote Now! Discover our plasma cutting service that offers the most precise and rapid solution for your projects. Share your needs, and our expert team will provide you with the best solution. For more information, you can visit our Contact page. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ROKVELAS, UAB

Lithuania

"- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000."

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

WATTSAN 1530 ROTATORY has a rotary device for cutting cylindrical products. This machine is purchased for cutting steel tubes, galvanized and stainless steel, aluminum, brass and other materials. The machine is most often used in aviation, aerospace and mechanical engineering, as well as for the manufacture of auto parts, advertising products and household appliances. You can install a radiator of any power: 300/500/750/1000/1500/2000/3000/4000/5000 Watts. Important: the machine is equipped with a protective cabin with a power of 1000 Watts. Optional fiber laser emitter: Max / Raycus / IPG. Each of them is distinguished by high accuracy and speed of work, durability, but there are also differences. IPG is considered a premium model, it gives the best result and speed. The service life of the emitter ignition unit is about 100 000 hours. The protective glass for the lens, which must be changed at least once a month. The lens itself needs to be renewed approximately once a year.

Request for a quote

VIRMER

Netherlands

WATTSAN 1325 BASIC fiber laser machine is an economical and practical machine for cutting thin sheet metal. The metal cutting machine works with stainless and carbon steel, copper, aluminum, titanium and other materials. This machine is often purchased for manufacture, such as aviation, astronautics and mechanical engineering. We can install Maxphotonics / Raycus / IPG fiber laser emitter for choice. The main advantage of a fiber laser over a gas laser is its high speed and accuracy of operation, as well as durability: the life of the ignition unit is 100,000 hours, i.e. years of continuous operation. The machine has a working table 1300x2500 mm. WATTSAN 1325 BASIC laser machine is a high-precision device with a reliable control system. It has a high-quality fiber laser emitter. Of course, such a device will last a long time, because the declared service life of the frame is 20 years.

Request for a quote

VIRMER

Netherlands

Fiber metal cutting machine WATTSAN 1325 TABLECHANGE is a large and high-precision machine for cutting stainless and carbon steel, copper, aluminum, galvanized plates and other materials. On this machine, it is possible to install emitters of the following powers: 300/500/750/1000 Watts, and from 1500-5000 Watts with a protective cabin. One of the main advantages of all fiber lasers is durability: the life of the ignition unit reaches 100 000 hours. And this is about 10 years of continuous work. The manufacturer also claims that the bed of this machine can last 20 years. There are two options for the working field for this machine: 1300x2500 mm and 1500x3000 mm (1530 TABLECHANGE). For smaller workpieces, the 1300x2500 mm option is suitable; for industrial production, it is recommended to purchase a larger working area. If you have any doubts about the choice of the working field, please contact our specialists for advice.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY CABINE is a powerful fiber laser machine, also known as a tube cutter. The device is equipped with a protective cabin for safe operation, as well as a rotary device. The rotary device takes the capabilities of your equipment to a whole new level. You can use the metal cutter like a regular cutter, and in a few minutes switch to the task of cutting tubes. The protective cabin is installed on machines from 1000 watts. This ensures the safety of the laser cutting operator, as well as minimizes the dangers of external influences. The machine is equipped with a fiber optic emitter: Max or Raycus or IPG. Such an emitter will last up to 100 000 hours of the most intensive work. If we talk about the intensity of work — the stand is weighted, crushes vibrations and will last 20 years, according to the manufacturer's information.

Request for a quote

VOSSE SP. Z O.O.

Poland

Plasma (gas) cutting service is an efficient metalworking method that is used in many industries. It uses a high-temperature electric arc to melt and cut through metals, resulting in a precise and clean cut, even for thick materials. It is an extremely versatile process that can be used for both straight-line cutting and the cutting of intricate shapes, making it invaluable in the production of metal structures, machine components or even artistic works.

Request for a quote

VOSSE SP. Z O.O.

Poland

Using state-of-the-art technology, we offer a laser cutting service that provides unparalleled precision and excellent workmanship. Our machinery is equipped with the latest equipment, enabling us to cut a variety of metals to the highest standards. Thanks to automated processes and the experience of our specialists, we are able to complete even the most complex projects with speed and accuracy that will meet the expectations of the most demanding customers. Laser cutting in our company is carried out on high-end fiber optic cutters processing materials according to the following parameters: - structural steel - up to 25 mm - stainless steel - up to 25 mm - aluminum - up to 20 mm - brass, copper, bronze - up to 8 mm Maximum dimension of the processed sheet 2000x4000 mm.

Request for a quote

MARXAM PROJECT

Poland

Laser cut companies have become quite prominent in metalworking industries. Choosing Marxam Project, you are choosing a reliable partner with decades of experience. Sheet metal laser cutting is a technology that allows you to quickly and cheaply obtain an element of any complex shape from various types of flat sheets. The undoubted advantages of laser cutting are: - cutting laser offers freedom of shapes, limited only by the properties of a material; - cutting metal with repeatability of details at the level of 100%; - for given types of materials and their thickness, the laser cut surface is of a quality that allows the elimination of the finishing process; - the best possible use of the surface of the material – thanks to the use of appropriate computer programs, with our laser cutting services, we obtain a large percentage of sheet metal use, and we can properly optimize the production process; - it allows to reduce the effect of heat on the deformation of the cut material

Request for a quote

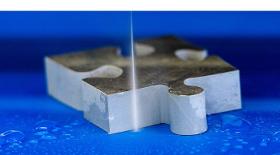

MARXAM PROJECT

Poland

Water jet cutting services allow to ensure high quality of the machined surface for details with large thicknesses and complex geometric shapes (high density of cutting lines on a small area, small diameters of holes – of even 1mm). The use of aqua cutting with high pressure, containing fine abrasives, allows to achieve new production effects, which were impossible or time-consuming and expensive using other methods. Using this method, we can process, materials such as: - Ceramic materials - Glass - Plastics - Titanium and its alloys - Materials sensitive to high processing temperatures - Structural, alloy and tool steels (of any degree of hardening) - Cast iron, steel - Copper, brasses, bronzes - Molybdenum and its alloys - Wood and wood-based materials Waterjet cutting technology is one of the most environmentally friendly processing methods. The abrasives used are of natural origin and are chemically inert, and the process itself does not generate any harmful waste.

Request for a quote

GENSAC METAL SAN. TIC. LTD. STI

Turkey

Each kinds of server chasis we manufacture.

Request for a quote

GENSAC METAL SAN. TIC. LTD. STI

Turkey

Gensac Metal, manufactrues all kinds of generators chasis & all metal spare parts to main generator manufacturers. With finished painting.

Request for a quote

PI-METÁL

Hungary

Unlike other technologies waterjet cutting is a cold-cutting process that can cut almost any material. It also provides a high-quality solution in cases where other methods even if applicable, but are less effective. By using this technology the surface will not be harmed, - no hardening, no humping, no melting and no gas formation. Cutting certain materials e.g.- hard plastic, plastic-coated metals - waterjet cutting is almost the only applicable method - as it does not damage the surface.

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice -control -Comes with a stop rod for repeatable cuts -Hassle-free performance

Request for a quoteResults for

Metal-cutting manufacturing - Import exportNumber of results

40 ProductsCountries