- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal powder ingots

Results for

Metal powder ingots - Import export

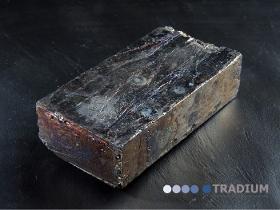

TRADIUM GMBH

Germany

At TRADIUM, dysprosium is available in the following form und for industrial supplies: - Dysprosium oxide - Dsyprosium metal, powder, ingots Your point of contact for dysprosium is: Jan Giese Phone: +49 (0)69 50 50 250 - 237 We are looking forward to hearing from you!

Request for a quote

TRADIUM GMBH

Germany

At TRADIUM, bismuth metal is available in the following shapes for industrial supplies: - Bismuth granules, ingots, metal needles - Bismuth powder - Bismuth oxide Your point of contact for bismuth is: Frank Meier Phone: +49 (0)69 50 50 250 - 234 We are looking forward to hearing from you!

Request for a quote

SB-TRADING (BVBA)_M

Belgium

Heavy density 9.75g/cm3. 2. Customized indium powder size 80mesh, 100mesh, 200mesh, 325mesh, 500mesh. 3. High purity virgin Indium metal 99.995% up. 4. Wide range of applications like the transparent electrode(ITO film), solder in electronic industry, Low melting alloy, bearing for high-performance engine, and the seal in low temperature, etc.

Request for a quote

MATTES KG

Austria

Heavy density 9.75g/cm3. 2. Customized indium powder size 80mesh, 100mesh, 200mesh, 325mesh, 500mesh. 3. High purity virgin Indium metal 99.995% up. 4.Wide range of application like the transparent electrode(ITO film) ,solder in electronic industry, Low melting alloy, bearing for high performance engine , and the seal in low temperature,etc.

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== MAGNESIUM INGOT The proportion of magnesium alloy is the lightest among all structural alloys, so the weight of aluminum or iron can be reduced without reducing the strength of the parts. Smelting from minerals into metals is mostly made up of raw embryos of various sizes and shapes. Magnesium Alloy Casting Ingots can be used to make all kinds of plates, wires and profiles, as well as for use in chemical industrial, military industrial and meter instrument manufacture, etc. In the elastic range, the magnesium alloy by the impact load, the absorption of energy than aluminum alloy, so the magnesium alloy has a good seismic noise reduction performance.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Our filter grade powders are available in a wide range of particle size distributions and are uniquely suited to produce sintered porous metal filters for demanding applications. Typical materials include a wide number of commercial alloys specifically tailored for filter applications. The alloys available include but are not limited to high performance Stainless Steels, Hastelloys®, Monels®, Inconels® and Nickel. We produce these alloys specifically for sintered filters in tightly controlled size distributions within the 10-250µm range for liquid and gas filtration. We routinely produce more than 25 different sizes of filter product and are happy to take on the challenge of exacting, custom specifications. Filter Powder Expertise We manufacture filter grade powders that are specially atomized to give the highly irregular shape required for precise filtration. Our plant has been producing water atomized powders for sintered

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We have a long and established history in serving the global Powder Metallurgy industry with substantial historical product developments and leadership representation at Metal Powder Industries Federation (MPIF). Our ability to engineer customized, structural metal powders through water atomization for Powder Metallurgy (PM) applications is world renown, particularly in the automotive and industrial markets. Powder Metallurgy (PM) is the process of pressing and sintering a metal powder into a near net shape part that offers numerous advantages over other metal forming technologies including: High customization such as size, alloy and properties Cost effectiveness and sustainability due to near net shape or net shape production Shape complexity without secondary operation Products We manufacture an extensive range of alloys to numerous customers specifications including chemistry modifications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel powder 304L is a corrosion resistant material that exhibits good property stability below 1000°F. 304L powder is often the most practical stainless steel choice for parts that need the benefit of an austenitic grade. 304 Stainless steel exhibits better overall corrosion resistance than 303 grade. This material is a good choice for parts that will not be subjected to demanding machining operations. A major benefit of this material is the balance of good material performance and economical cost. The 300 Series Powders are austenitic stainless steels typically used for powdered metallurgy (P/M) press and sinter applications to make near net shape parts for a variety of industrial applications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hardfacing Powders are manufactured to have the precise size, shape, and chemistry required for optimal thermal spraying characteristics. Our powders are available in a wide variety of alloys to give the workpiece desired finished qualities - whether it’s good machinability, abrasion resistance, corrosion resistance, ductility, hardness, or high strength. No matter the application, we have a powder that can be manufactured to your exact specifications and meet your coating needs. Hardfacing Process Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to give it a specific hardness, wear resistance, or corrosion resistance. This process requires the appropriate alloy and particle size distribution for a specific deposition technology. Appropriately selected powders yield the best properties and manufacturing efficiencies.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The 300 Series Powders are austenitic stainless steels typically used for powdered metallurgy (P/M) press and sinter applications to make near net shape parts for a variety of industrial applications. Stainless steel powder 303L is a free machining, austenitic grade that offers moderate corrosion resistance. This stainless steel is sintered in either a partial vacuum or a hydrogren atmosphere to improve ductility and corrosion resistance. 303 Stainless steel powder is a sulfurized grade that is an excellent option for parts that require secondary machining operations, such as food service equipment, pump components and nonmagnetic housings.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our metallurgists specialize in the design, development and production of specialty metal powders manufactured through advanced high-pressure water atomization technology. We work alongside our customers to develop custom metal alloy powder solutions to exacting specifications for critical applications. Our expertise and nearly 50 years of history in water atomization of specialty metal powder products has led us to supply a huge number of market sectors ranging from automotive to semiconductor to aerospace across the test globe. Water Atomization Process We employ an advanced high-pressure water atomization process to engineer highly customized metal powder. Our technology is proven to achieve fine particle size distributions, enabling our metallurgists to produce precision metal powder products.

Request for a quote

ARTAN INTERNATIONAL

Switzerland

Commodity: Ultra pure and ultra fine copper powder (UPC), not radioactive End Use: Aerospace industry and Medical industry Composition (isotopes): 63Cu 69.1% +/- 0.05% and 65Cu 30.9 % +/- 0.05% High purity: 99.9998 % Particle size (granulometry): from 2 μm to 10 μm Minimum order quantity: 200 kg Origin: Non-criminal and Non-Sanctioned Country Packaging: under Argon, 2 kg bottles Location: Germany IGAS Research certified Availability: Currently available

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hardfacing Powders are manufactured to have the precise size, shape, and chemistry required for optimal thermal spraying characteristics. Our powders are available in a wide variety of alloys to give the workpiece desired finished qualities - whether it’s good machinability, abrasion resistance, corrosion resistance, ductility, hardness, or high strength. No matter the application, we have a powder that can be manufactured to your exact specifications and meet your coating needs.

Request for a quote

PE OMEGA

Ukraine

We are looking for real buyers familiar with the purpose of extra-pure metals. We, as manufacturers of high-purity metals, announce that we can supply the following products: 1. High purity copper ingots (grades C5N, C6N) Quality: 99.999% Cu of oxygen-free copper. Quantity: up to 50,000 kg monthly. Price FCA: 385 euro/kg. Quality: 99.9999% or more for the requirements of special thermal and electrical conductivity, cryogenic, acoustic and other properties, at a negotiated price. C6N ingots up to 500 kg per month. Price FCA: 3850 euro/kg. 2. Ultrafine copper powder (PMU) of isotopic composition Chemical purity - 99.999%, average particle size 3 - 12 microns on request. Quantity: up to 25 tons monthly. Price FCA: 385 EUR/kg. Chemical purity - 99.9999%, average particle size 3 - 12 microns on request. Quantity: up to 5 tons monthly. Price FCA: 3850 EUR/kg. Prices are on FCA sale condition, factory manufacturer.

Request for a quoteResults for

Metal powder ingots - Import exportNumber of results

15 Products