- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal injection moulds

Results for

Metal injection moulds - Import export

AMETEK SPECIALTY METAL PRODUCTS

United States

Since the 1980’s, we have been a leading producer of superfine powders for Metal Injection Molding (MIM). Our expertise and advanced atomization technology enable us to produce very fine MIM powders down to 10µm. Products and Sizes Our MIM water atomization technology is compatible with most conventional high-performance stainless steels and alloys. Special size distributions are available as well as some standard sizes. Grades: 17-4PH®, 70/30 Fe/Cr, 430L, 316L, other 300 Stainless Steel series Sizes: Typically smaller than 20µm Austenitic Stainless Steels 316L used in MIM applications which require good corrosion resistance, strength and ductility. Also available 304L and 310L. Ferritic Stainless Steels 430L ferritic stainless steel combines good magnetic response and some corrosion resistance. Also available 409L, 410L, and 434L.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Bilsa works with many companies around the globe - in the industries of defence, automotive, medical, electric, hand tools, and textile. Our customers are well aware that they choose us not only for production but the service we provide them. Our experts will lead you to receive the best manufacturing quality. No matter what the volume is, we make sure to meet the desired quality and the performance. We manufacture to create the excellence that our customers deserve.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

AFT-HUNGARY KFT

Hungary

Part size: 0,1-100+ grams Complexity, tight tolerances, high volumes in serial Improved ultimate tensile strength, better micostructure, improved elongation, better process capability (compared to other production methods) Customised feedstock ISO/TS certifications according to automotive industry high requirements In-house machining, required surface finish, HT and other technologies according to customer requirements

Request for a quote

AFT-HUNGARY KFT

Hungary

Part size: 0,1-100+ grams Complexity, tight tolerances, high volumes in serial Improved ultimate tensile strength, better micostructure, improved elongation, better process capability (compared to other production methods) Customised feedstock Machining (in-house), HT, surface finishing according to customer's requirements

Request for a quote

AFT-HUNGARY KFT

Hungary

Part size: 0,1-100+ grams Complexity, tight tolerances, high volumes in serial Improved ultimate tensile strength, better micostructure, improved elongation, better process capability (compared to other production methods) Customised feedstock, according medical requirements Required machining (in-house), HT and surface finishing according customer's needs

Request for a quote

AFT-HUNGARY KFT

Hungary

Part size: 0,1-100+ grams Complexity, tight tolerances, high volumes in serial Improved ultimate tensile strength, better micostructure, improved elongation, better process capability (compared to other production methods) Customised feedstock ISO/TS certifications Machining (in-house), HT and surface finish according to customer requirements

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

Using thermoforming as an alternative to metal, foam or injection moulding often makes economical sense, especially where mid-size production runs or complex components are involved.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Below are a few reference objects that we have been able to work on as part of a wide variety of project tasks in recent years: Audi: all RS models since 2000, R8, R8 2015 Bentley: Mulsanne, Bentayga BMW/Mini: Clubman, 3 series Ferrari: 599 GTO Lamborghini: Gallardo, Murcielago, Aventador Mercedes: S-Class, SLS, Actros Porsche: 997, 911 I panel, door trim, center console, greenhouse, interior trim, trim, steering wheel, seats, carpet trim, infotainment system, instrument cluster, mirror, selector lever, switch panel, trunk, engine compartment cover. Wheels, brakes, wheel suspension, exhaust system, engine components, tank, lines. Plastic injection moulding, metal casting, forging, forming, tube processing, painting, galvanic surfaces, lamination, leather covering, upholstery and sewing.

Request for a quote

KULLEN-KOTI GMBH

Germany

Should you have not been able to find the suitable lath brush for your application although our standard range is most versatile, we trust that our special types might come up perfectly to your requirement. They also offer best quality to meet your most particular wishes. You can choose for instance between frame shape, angled or arched shape; special fixing devices such as round drill holes or slots; threaded, grooved or clamped holding devices. In case of large-scale requirement we also provide especially moulded plastic or metal cores made either by injection moulding or diecasting. Please see the index card "brush assembly" for the core material. Furthermore we have wood, steel, stainless steel, light or heavy metal in our assortment.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

PLANSEE SE

Austria

Plansee charge carreiers from refractory metals are dimensionally stable at high temperatures and in contrast to graphite parts they are also suited for high-vacuum furnaces. MLR with its superior creep resistance and retained ductility after high temperature operations is the ideal material for mechanically loaded furnace parts. Plansee designs and fabricates furnace fixtures to customer specifications, e.g. for aeronautics, glass industry, Metal Injection Molding (MIM), commercial heat treatment and various other thermal processes. Alongside molybdenum and tungsten, we primarily manufacture our charge equipment from TZM and ML. The creep resistance of these alloys is ten times better than that of pure molybdenum and they are also exceptionally ductile. As a result, our charge systems are perfectly equipped to cope with frequent changes between high and low temperatures.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK has the metallurgical expertise to produce specialty powders for super-niche and highly engineered applications. Our experience has made us a global leader in the field. Customized and Specialty Alloys Utilizing high pressure water atomization under carefully controlled conditions, we develop innovative powders in an extensive range of standard and custom alloys. Niche Applications Our high alloy powders are used in specialty segments including Sintered Metal Filters, Fiber – polyester and nylon production, Plastic Compounding, Hardfacing and Surface Coating, Powder Metallurgy (P/M), and Metal Injection Molding (MIM). Typical alloys include

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

CAFUTA D.O.O.

Slovenia

We offer structural, sheet metal forming, injection molding and CFD simulations.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

With Conform® components our customers can reduce their procurement and assembly costs: We handle the preceding processes thus enabling slimmer procedures at our customers’ own production facilities. So that we can meet the wide variety of component needs for our customers, we work within a network of certified partners. Some examples of components made to customer specifications: cold-formed parts in steel cold-formed parts in aluminium rubber decoupling elements plastic injection-mouldings stampings metal bending parts non-detachable washers or sealing rings

Request for a quote

ITOM LTD

Bulgaria

Manufacturing injection moulds, blow moulds, dies ...other device and equipment Metal cnc parts production Plastic parts. Injection moulding of plastic parts. Assembling of components.

Request for a quote

NOVELTY STEEL

Turkey

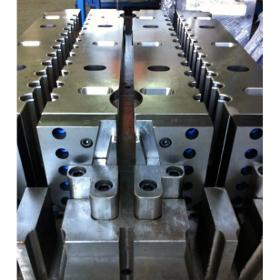

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions, ISO 9001:2015 & IATF 16949 accredited

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quoteResults for

Metal injection moulds - Import exportNumber of results

44 ProductsCountries

Category

- Injection moulding of rubber and plastic (5)

- Plastic products for engineering (5)

- Finished Metal Products (4)

- Shaping - steels and metals (4)

- Injection, plastics - machinery (3)

- Plastics moulding (3)

- Testing equipment (3)

- Metal powders (2)

- Packing and packaging - machinery and equipment (2)

- Casting, steel (1)

- Industrial furnaces (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission - components (1)

- Plastics - machines and material for industry (1)

- SMALL METAL PARTS (1)

- Sintering - steels and metals (1)

- Steel & Metals (1)

- Vehicles - mechanical components and parts (1)