- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal hardening

Results for

Metal hardening - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quote

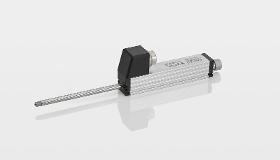

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer in compact design with one-sided actuating rod and return spring; long life span and high adjustement speed; Flexible mounting via clamps, bushing mount or flange plates; probe tip with pressed-in hardened metal ball

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer in compact profile design with double-sided supported actuating rod and internal return spring; very high repeatability and adjustement speed; probe tip with pressed-in hardened metal ball, long life span

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Absolute transducer in compact profile design with double-sided supported actuating rod and internal return spring; NOVOPAD non-contacting, inductive measuring principle, Teach-in function with status LEDs, probe tip with pressed-in hardened metal ball, long life span

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XUFENG TOOL TECH GROUP LIMITED

China

Material :Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Processing:turning, milling, drilling, wire EDM, welding Tolerance:+-0.05mm, as required Suface treatment: anodizing, electroplating

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, etc. Surface treatment: Customer's Request, color anodizing Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP) Tolerance: Customer's Drawing Request, ±0.01-0.02

Request for a quote

ALPHA LASER GMBH

Germany

The AL-ROCK is a laser hardening system for surface hardening with a self-propelled caterpillar track. The laser can be brought directly to the workpiece. Time-consuming removal of the components to be hardened can often be avoided. The robot arm easily reaches the hard-to-reach places on the workpiece. All common metals can be hardened, e.g. Quenched and tempered steels, cold work steels and cast steel or gray cast iron. The material must have at least 80% pearlite. The degrees of hardness that can be achieved are identical to those of conventional hardening processes. In free 3D movements, the laser beam precisely follows even the most demanding three-dimensional workpiece contours, for example on tracks along closing edges. Pimples, scar structures. Simple points are also not a problem. Only the free access of the laser beam to the surface to be hardened is required. And the AL-ROCK can do even more - on request, the laser robot can also be used for laser welding.

Request for a quote

ERC ADDITIV GMBH

Germany

ERC NANO 10-9 motor oil additive forms an ultra-thin functional layer in the engine interior and thereby reduces friction, wear and sediments. It improves the oil supply for improved engine performance and lower fuel consumption. THE EFFECT Even apparently smooth metal surfaces turn out to be rough when viewed under the microscope. Friction leads to wear and higher fuel consumption. ERC NANO 10-9 Motor Oil Additive „hardens“ the metal surface by chemical means, forming a smooth protective layer on surfaces subject to high frictional stress by building up chemically active nano structures (“bottom-up”). This leads to optimum engine power and lower fuel consumption. THE ADVANTAGES AT A GLANCE - Highly effective reduction of friction and wear through chemically active NANO structures - Cleans engine and oil ducts free of deposits - Reduces noise and stabilizes oil pressure - Improves stability under load of the basic oil - Protects against oil ageing and corrosion

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Steels of the highest tensile strength • Long chipping materials • Stainless steel • Titanium based alloys • Nickel based alloys • Special bronzes

Request for a quoteResults for

Metal hardening - Import exportNumber of results

11 ProductsCountries

Company type