- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal gaskets

Results for

Metal gaskets - Import export

FLEXIND B.V.

Netherlands

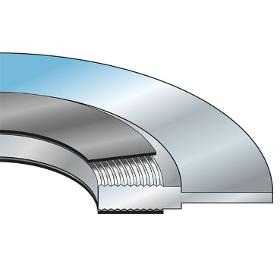

Gaskets with metal inner ring provide special protection against blowout when sealing critical or hazardous materials. The stainless steel inner ring provides excellent protection of the soft gasket material against erosion and corrosion, while also preventing contamination to the medium in the pipe.

Request for a quote

HEBMÜLLER GMBH

Germany

Traditionally, our rubber-to-metal seals are used in the engine and transmission sectors, often with the elastomer FKM / FPM.

Request for a quote

ALKIM PETROKIMYA

Turkey

It was formulated in order to clean sloughed oil residuals, residuals and stains such as residue resin, corrosion thanks to the detergent and its dispersive additives with rapid engine inner space washing and crankcase cleaning e ects. Solves adhesive accumulations at piston and rings; and unconstraines the valves and lifters. • Cleans the engine e ectively; and keeps the accumulations pending in the liquid. • It does not harm the gaskets, metal parts and other materials in the engine. • Improves the performance, fuel economy and engine power. • Compatible for all of gasoline and diesel engines

Request for a quote

ALPIN RUBBER AND PLASTIC TECHNOLOGIES

Turkey

Our products are manufactured in conformity with Reach, Rohs and Pah. Production is carried out in conformity with FDA. Our products are made in the diameter, length and hardness you want.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

SPM has accrued more than 60 years of experience in manufacturing solid metal gaskets for high pressures, high temperatures and corrosive agents applications that comply with API6A, ASME B16-20, EN 12560, and ISO 10423 standards. Our products are certified and approved by the leading international contractors. We feel that a gasket is, above all else, an element of safety. Traceability is guaranteed: Each lot of materials supplied has passed our quality control system (ISO 9001: 2008 and API Spec 6A-0200) and our lots are systematically inspected by PMI-type testing. Standard and special gaskets: Our expertise is focused on the complete manufacturing of standard or special metal axisymmetric gaskets. A large stock of standard gaskets is available. Whatever your needs might be, we have mastered all of the requirements set out by the standards as well as customers’ special needs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

SPX FLOW Bolting Systems is pleased to introduce the FLS15 & FLS15-ST hydraulic spreaders. These units are ideal for pipe and flange repair. They can also be used for removing elbows, gasket and metal seal replacement on couplers, heavy equipment maintenance, and many other tasks. The spreaders are capable of developing up to 15 metric tons of force, are lightweight (only 7 lbs. [3.2 kg]), and easy to use due to their ergonomic design. 33,000 pound (15 metric ton) wedge driven spreader Jaws fully supported by wedge for excellent durability Low friction provided by heavy-duty extended-life lubricant Ideal for flanges with narrow gaps - only .2 inches (5 mm) required for entry Very high strength due to special alloy used Compact and lightweight design - only 9.9 inches (252 mm) long at a weight of 7 pounds (3.2 kg) Easy to use - ergonomically balanced handle (Optional) Suitable for the offshore environment due to superior corrosion resistance Quick adjustments for various tasks due.

Request for a quote

GAMBIT LUBAWKA SP. Z O.O.

Poland

Gambit offers a wide range of high quality fl ange gaskets, meeting various requirements. Different types of fl anges and different chains of dimensions are applied. For fl anges defi ned this way Gambit Lubawka Sp. z o.o. manufactures gaskets according to appropriate norms describing construction and sizes of gaskets. Numbers of these norms are referred to in description of individual types of gaskets. We also manufacture gaskets beyond the chains of dimensions, according to requirements defi ned by a customer. In order to meet our customers’ demands related to various fl ange systems, we manufacture different types of gaskets: 1. GAMSEAL gaskets cut from AF series gasket sheets, 2. GAMBITGRAF gaskets cut from graphite sheets, 3. GAMPROFILE kammprofi le, 4. GAMSPIR® spiral wound gaskets, 5. AZMES gaskets, 6. GAMFLEX metal jacket gaskets.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

KGA ENCLOSURES LTD

United Kingdom

Product Features: • Electronic instrument enclosures, designed for mounting printed circuit boards or DIN rail mounted components. • The polycarbonate material carries a UL flammability rating of UL94 5V and is suitable for outdoor use. • Lid and mounting holes are located outside of the gasket seal. • Lid is secured with self captivating M4 stainless steel machine screws (included), threaded into integral stainless steel bushings (for repetitive assembly and disassembly). • Heavy duty 16 gauge galvanized steel panels available. • All stainless steel hardware to avoid corrosion caused by dissimilar metals. • Gasket is a preformed, high temperature U.L. listed silicone rubber. Gasket is replaceable. • Gasketed lid with two piece "tongue and groove" construction provides protection against access of oil, dust and water. • Internal DIN rail mounting tabs.

Request for a quote

CBG COMPOSITES GMBH

Germany

High-temperature vacuum-formed products made from biosoluble ceramic fibres are lightweight and solid parts or structural elements that can be used at temperatures up to 1.400 °C in air and in aggressive environments, including direct contact with liquid metals. — 100% biosoluble — high temperature resistance — low thermal conductivity — high chemical resistance * — low weight — good tear resistance — high flexibility — easy processing — complicated geometries can be produced — recyclable * to achieve higher acid resistance, a special coating is required. Available from manufacturer. Application: Burner plant components, crucibles, thermocouple housings, coupling devices in continuous casting plants, channel elements of metal troughs, inlet device in the melting of non-ferrous and ferrous metals, gasket in aluminium foundries, gaskets in blast furnaces, expansion joints, pipe insulation, catalyst insulation, repair work in the high temperature range.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quote

J-FLEX RUBBER PRODUCTS

United Kingdom

Whatever your requirements, J-Flex can help with a vast array of bespoke rubber mouldings, large or small and in a wide range of polymers. We guarantee you top quality mouldings every time using our ISO9001 batch traceability procedures. We sample new moulds to your complete satisfaction and approval before we commence bulk supply. Our polymer range is vast – we can offer: Natural, Neoprene, Nitrile, EPDM (including EPDM conforming to EN45545:2013 + A1:2015), Butyl, Hypalon®, HNBR, CXNBR, Silicone, Fluorosilicone, Viton™, Fluoroelastomers, Aflas® and Perfluoroelastomer. We mould by compression, transfer and injection moulding techniques. Bellows Discs Covers Gaiters Boots Vibration Mounts Grommets Diaphragms Sheets Rubber / Metal Bondings Cups Suckers Balls Gaskets ‘O’-Rings Rubber Seals J-Flex – for rubber mouldings, including Silicone, FKM, EPDM and much more.

Request for a quote

NOWENTA

Slovakia

In house we are producing complete cartridges, but also many of the filter elements, including plastic and metal spiro and gaskets. The pleating of the filters is a special science in which we take great pride. The pleating can come with many different enhancements ensuring optimal performance for various operational settings, you can choose between dimpling, pleat lock, embossed or minipleat. In house we have also specialized in an ultrasonic welded strap – where no chemicals or glue has been used, the Weltech secures consistent pleat spacing and minimizes trapping of the dust behind the strap. Plus, it has the advantage of better cleaning performance and more even airflow.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

CTT showcases an exceptional synergy of technology and precision in the field of numerical control (CNC) machining for ultra-high purity gas VCR components. By integrating cutting-edge CNC machining technology with high-quality stainless steel, CTT ensures that VCR accessories are resistant to corrosion and wear, maintaining peak performance even under extreme environmental conditions. The CNC machining process lies at the core of CTT's manufacturing approach, meticulously carving complex details and precise dimensions from raw materials. To further enhance the durability of the components, CTT employs electropolishing, a technique that not only refines the surface quality but also bolsters their corrosion resistance.

Request for a quoteResults for

Metal gaskets - Import exportNumber of results

15 ProductsCountries

Company type