- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal complex

Results for

Metal complex - Import export

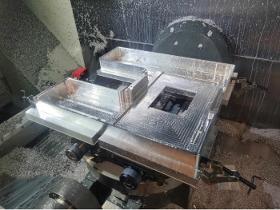

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

We specialize in CNC processing of small to medium series of milling parts (1 – app. 5000 pieces). Our main activity is production of individual custom components, from less demanding to very demanding and complex ones. Specialized in smaller productions has its own advantages. We can individually devote ourselves to our partners. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Tower is a group of manufacturing facilities, offering one-stop solution for quality mechanical products with total lower cost in China. We can supply a full-range of metal products, such as sheet metal fabrication, cnc machining parts, casting parts, especially assembly parts. Product market range cover auto industry, medical industry,agricultural machinery, sport industry and so on. Because of our complete equipments, we are very suit for making all kinds of Assembly Parts. All of our products are customized by customer's drawing. Please feel free to send us your drawing or sample to customize!!!

Request for a quote

LISINE EPSTEIN COSMETICS BV

Belgium

This intensely pigmented, compact and long-lasting eye shadow will follow you all day long! Thanks to the ultra-handy duo format you can take it everywhere! The formula enriched with a unique complex of metallic pigments puts a delicate and intense iridescent veil on your eyelids and decorates your look at its best. Apply with your finger for a natural effect or with an applicator for a more intense color.

Request for a quote

LISINE EPSTEIN COSMETICS BV

Belgium

This intensely pigmented, compact and long-lasting eye shadow will follow you all day long! Thanks to the ultra-handy duo format you can take it everywhere! The formula enriched with a unique complex of metallic pigments puts a delicate and intense iridescent veil on your eyelids and decorates your look at its best. Apply with your finger for a natural effect or with an applicator for a more intense color.

Request for a quote

ACTIVETOOL UNIPESSOAL

Portugal

Machining services for large and complex metal structures.

Request for a quote

IGUS® GMBH

Germany

Polysorb Disk springs delivery program De [mm]: Di [mm]: disc springs are annulus discs stressable in the axial direction, which are turned over in the shape of a disc in the axial direction. disc springs provide a more favorable space usage than other spring types. They are particularly suitable for designs that demand a small spring deflection. + When not to use Polysorb Disk springs? For the implementation of specially flat load deflection curves that are possible with metal only with considerable complexity and expenditure (slotted versions). For compensation of axial clearance and manufacturing tolerances For vibration compensation For noise dampening When an antimagnetic material is required For electrical and thermal insulation When no corrosion problems should arise When lubrication is not necessary For low weight For low space requirement – When not to use polyserb disk springs? When constant spring forces are necessary over a wide temperature range When high spring forces are required The spring deflection of the disk spring is relatively small. Therefore a number of disk springs are combined in practice. Alternatively layered disk springs enhance the spring deflection in proportion to the number, whereby the overall spring force is as large as the force of the individual disk spring. To increase the force, the disk springs can be layered in parallel as a spring packet. Chemical resistance Polysorb disk springs are resistant to many chemicals. iglidur® A500 has a higher resistance than iglidur® J. Medium Resistance iglidur® J iglidur® A500 Alcohols + + Hydrocarbons + + Fats, oils without additives + + Fuels + + Diluted acids 0 to - + Strong acids - + Diluted bases + + Strong bases + to 0 + Humidity absorption The low humidity absorption allows them to be used in wet or humid environment. Polysorb® disk springs absorb humidity. Thereby their mechanical properties alter. In the worst application that can be thought of - extremely long application in water - Polysorb® disk springs still exhibit high spring force. iglidur® Standard environment saturated in water J 18 15 A500 24 23 Increased operating temperature Increased temperatures lead to the decline of stiffening in polymers. Polysorb® disk springs exhibit a maximum spring force of 8 N even at the maximum permitted temperature of 80° C. See figure for relationship of spring force to ambient temperature. Polysorb Disk springs long-term tests X = downward deflection [%] Y= spring force [N] A = JTEM-10 B = A500TEM-10 Figure 35.1: Spring force depending on the percentage of deflection measured in installation size 10 X= Ambient temperature [°C] Y= Maximum spring force [N] Figure 35.2: Influence of the ambient temperature on the spring force, measured on JTEM-10 Polysorb Disk springs delivery program De [mm]: Di [mm]: Dimensions according to DIN 2093

Request for a quote

SUN CHEMICAL - COLORS & EFFECTS NETHERLANDS B.V

Netherlands

Despite being a monohydrate salt (crystallized from clod water) the salt can also crystalize in hot water to become anhydrous (water-free). This property becomes possible as it has a high melting point of 156 degrees Celsius. This property along with the ability to bond with other metal ions to form complex molecules makes it a good chelating agent for several industrial applications. Some of these applications include the removal of limescale from evaporators and boilers.

Request for a quote

MEDIZIN- UND LABORTECHNIK ENGINEERING GMBH DRESDEN

Germany

Pyridine-free determination of total cyanide and weak-acid dissociable cyanide content Determination according to flow analysis method DIN EN ISO 14403 Integrated UV and thermo digestion for selective liberation of cyanide from metal complexes Elimination of matrix interferences by membrane transfer of hydrogen cyanide Very high sensitivity through enrichment because of the membrane transfer with stationary acceptor Measurement ranges: free Cyanide 0,02 - 1 mg/l FCN total Cyanide 0,02 - 1 mg/l TCN The analyzer Cyanos is a compact standalone Cyanide analyzer with integrated autosampler.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

THE BENEFITS OF TWO WORLDS Series components made of metal with complex shapes are usually very time-consuming and expensive to put into production -- but luckily there is now a superior alternative for these kinds of demanding workpieces in the form of MIM technology from Zimmer Group! The MIM process allows us to manufacture metal parts of almost any shape using an injection molding process, as easily as though it were plastic! This process lets us elegantly combine the geometrical freedom of plastic injection molding with the outstanding rigidity and wear characteristics of metals. The result is a thoroughly impressive technology for manufacturing metallic series production components with complex shapes -- and at very attractive prices, too!

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

We employ welding robots to join complex metal wire parts made of steel or aluminium to form an assembly. This in turn leads to complex bent wire components for the automotive industry, such as brackets for cushioning frames, and eyelet fastenings.

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs.Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Current transmission has to be assured, even when the application is greasy or oily. This is where our metal gauze brushes come in. What challenges have you got for us? MACK metal gauze brushes are capable of breaking through the oil coat which develops between the stator and the rotor during wet running, thereby ensuring permanent surface contact and power transmission. The versions available range from the simple metal gauze brush without fitting to the complex telescopic metal gauze brush for telescopic current supply.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Hai Tong is one of the leading manufacturer of high-volume, precision metal stampings for OEMs in the medical, automotive and electronics industries. Our skilled workers using in high speed metal stamping process to produces complex stamping parts which are of the highest quality standard and one stop solution for your specific parts. High speed precision stamping is the most cost-effective solution to produce small, tight tolerance but large volume parts, we can work with a variety of materials, such as copper alloys, stainless steel and carbon steels, and spring steel, enriched with years of experience in fabricating electronics metal stamping parts and medical stamping parts leads us to be top manufacturer who have enough knowledge to make the most complex stamping parts with stable quality and on time delivery. When components are produced through high speed stamping, the assembly process is also greatly simplified.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera supplies precision metallized ceramic components in aluminum oxide ceramics for the military, medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.

Request for a quote

OEN CHEMICALS GMBH

Austria

Chemical application and strengths: Despite being a monohydrate salt (crystallized from clod water) the salt can also crystalize in hot water to become anhydrous (water-free). This property becomes possible as it has a high melting point of 156 degrees Celsius. This property along with the ability to bond with other metal ions to form complex molecules makes it a good chelating agent for several industrial applications. Some of these applications include the removal of limescale from evaporators and boilers. The industrial-grade citric acidis one of the active agents in the preparation of kitchen and bathroomcleaning agents. It is a strong breach with a PH of about 3.2, which makes it a good solution of removing rust from metals such as steel as it combines with rust particles with ease. In the same line, it reacts with free ions on the surface of stainless steel to prevent further corrosion.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic ring in aluminum oxide ceramics for the military,medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization. Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Request for a quote

CRAEMER GMBH

Germany

Craemer is a specialist for constructing and manufacturing complex metal components and a well-known international supplier for the automotive, commercial vehicle, large domestic appliance and heating industries. The sheet metal components are sold to leading car producers, such as BMW, Mercedes Benz, GM, Volkswagen and Audi. Miele and other world brands are being supplied with white goods. The Craemer Group is one of the leading European manufacturers in the high volume serial production of car-modules, particularly components for seating structure and seatbelts. We process: sheet steel, high-strength sheet steel, high-grade steel and aluminium sheet Manufacturing process: hydraulic and mechanical presses with progressive die, transfer and servo direct technology as well as modern facilities for assembly production. Press capacity of between 3,150 and 25,000 kilonewton at a maximum table-length of 8,000 millimeters

Request for a quote

SP GROUP

Spain

Rclosing Efficient is a flexible high-barrier laminate with properties that permit re-closure. It is used as a lid for trays principally made from our APET EFFICIENT material. The laminate is characterised by being more sustainable than others as it is thinner and contains no chlorine products. In a triple complex it is available from 75 microns. Rclosing Efficient ensures the lid falls smoothly and firmly onto the tray so that the packet is re-closed and the preservation time increases during the established consumption period. As with previous openings, it ensures the re-closure is uniform. It can be made with transparent, white and metallic complexes.

Request for a quote

AXINAR SMPC

Greece

Equipped with advanced CNC machinery, including lathes, mills, plasma cutters, rollers, and welders, we have the capabilities to manufacture a wide range of precision metal parts to your exact specifications. With a production capacity of 3000 tons per year, we're well-equipped to handle orders of any scale.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Ready-to-install trunking systems – on time and at a fixed price Practical cable routeing – this means the combination of high-grade trunking products with a comprehensive range of services covering design, tools and installation. Customers can expect higher productivity, further rationalisation and cost savings. Cutting and fixing metal trunking by hand is complex, personnel-intensive, expensive and often involves time-consuming reworking. PFLITSCH manufactures made-to-measure, ready-to-install trunking assemblies from CAD drawings efficiently and rationally. This saves substantial time for the customer and relieves his staff of many routine tasks. Delivery is made on the scheduled date and at a fixed price, which can also include installation on site if desired. Your advantages: Transparent and cost-effective total price Designed to drawings Automatically generated parts and ordering lists Delivered on schedule Optimised production planning Relief of your staff

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Xu Feng offer CNC Milling part including 3- axies ,4-axies and 5-axies ,so no matter parts with simple or complex structure ,we can make it as per client's part design or sample,cnc milling torance we can reach 0.05mm,part material we milled usually is Aluminum,brass ,copper ,brozen,stainless steel and plastic (PP,PC,ABS,POM,PVC,PA66+30%GF) CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. CNC milling is one of the most flexible machining methods and able to make a wide range of custom parts. CNC milling is a cutting process in which material is removed from a block metal or plastic by a rotating tool. The cutting tool (called a “mill”) is moved in all three dimensions to cut a desired shape from stock.

Request for a quote

BSI CLEANING

Luxembourg

Due to the combination of materials forming them (polymers, glass, metals etc.), composites have complex surface properties. Atmospheric plasma opens the way to a high-quality surface finish as it allows cleaning and activation in a single stage, facilitating processes such as painting and varnishing. As an ecological and efficient technique, plasma is able to replace the most common toxic treatments. Advantages: - Uniform treatment easily integrated into both automatic and manual production. - delicate care of the part to be treated - Easy to implement, rapid treatment - Complete elimination of wet chemical products in the cleaning process - No neutralisation of the waste water, no elimination costs - No heat or steam generated in the workplace - Highly reliable and efficient cleaning process - Marked improvement in hydrophilic properties - Less staff required

Request for a quote

3D-MICROMAC AG

Germany

The DMP machine solutions are designed for flexible series production of complex metal components using micro laser sintering. The DMP machine series is the perfect solution to achieve superior detail resolution, highest surface quality, unrivalled accuracy, and very high part density. It offers high flexibility, low operating costs and user friendliness. The system includes a zero point clamping system for easy post-processing at the highest accuracy level and inert gas atmosphere including gas purifying based on industry standards. The DMP systems are able to process non-reactive and reactive materials, e.g. stainless steel, molybdenum, tungsten, titanium, and gold. The Micro Laser Sintering technology has been developed and is continuously improved by 3D MicroPrint GmbH. Superior detail resolution Highest surface quality Unrivalled accuracy Very high part density

Request for a quote

AFT-HUNGARY KFT

Hungary

Precision metal components produced by MIM. Complex shapes, tight tolerances, high quantities in serial,quality according highest standards. Part size: from 0,1 to 400 grams. Various materials, customised feedstock according customers needs, in-house compounding Full service from planning to finished product, including required machining (in-house) and surface treatment, cooperation with certified European suppliers. IATF 16949 and ISO 9001 certified manufacturer.

Request for a quote

"KERTEX ENERGIJA" UAB

Lithuania

Heat exchangers, tanks, containers, boilers, metal structures, pipelines, etc. are complex, so the most effective way to clean them is by using equipment with exceptional power. Our company has high-pressure cleaning equipment with working pressure of 1000 bar (193 l/min). These and similar technical parameters also apply to other industrial cleaning equipment operated by our company

Request for a quote

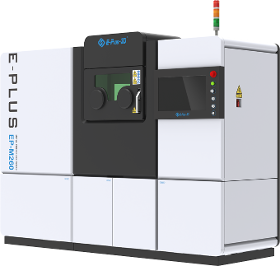

EPLUS3D TECH GMBH

Germany

The EP-M260 is an industrial grade metal 3D printer that uses advanced metal powder bed fusion (MPBF) technology. It is capable of easily and quickly converting CAD data into high-performance, complex structure metal parts. The 3D printer is an ideal choice for medium sized parts and small batch production.

Request for a quote

VACUUM EL SYSTEM LTD.

Bulgaria

Vacuum El System provides a wide range of welding services for mild steel, stainless steel, nickel alloy and aluminum parts. Our extensive expertise ranges from welding of simple metal frames, through complex cabinets, to very complex gas valve and vacuum chamber assemblies. Highly skilled workforce, following recognised International Standards (EN ISO 1011, EN ISO 5817), ensures all assemblies meet design specifications with excellent performance. Our development programs constantly improve the technical, drawing- interpretational, industrial safety and measuring skills of employees, passing on the benefits to the customer. We operate the latest technology and equipment from leading companies (Miller, ESAB, Fronius). We provide: TIG Welding MIG/MAG Welding Spot Welding

Request for a quoteResults for

Metal complex - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Ceramics, industrial (2)

- Cosmetics (2)

- Industrial sheet metal work (2)

- Milling - steels and metals (2)

- Precision mechanics (2)

- Shaping - steels and metals (2)

- Ceramics, refractory (1)

- Chemical catalysts (1)

- Cleaning, industrial (1)

- Food packaging (1)

- Forming - steels and metals (1)

- Freeze drying - machinery and equipment (1)

- Import-export - chemicals and pharmaceuticals (1)

- Industrial cabling (1)

- Joints, pneumatic (1)

- Laser - cutting and welding machines (1)

- Moulds, plastic and rubber industry (1)

- Printers - computer (1)

- SMALL METAL PARTS (1)

- Steels and metals - forming and cutting (1)