- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mass flow controllers

Results for

Mass flow controllers - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Mid-frequency magnetron sputtering technology has gradually become the mainstream of sputtering coating technology. Coating: Multi-function metal coating, composite membrane, transparent conductive coating, Increase return to shoot coating, electromagnetic shielding coating, decorative coating, etc. Power supply: DC magnetron sputtering power supply, MF sputtering power supply, high pressure ion bombard power supply. Target: DC magnetron sputtering target, MF twin targets, planner target, cylinder target. Vacuum chamber structure: Vertical signal door, Vertical double doors. Pump system: Molecule pump (diffusion pump)+Roots pump+ Holding pump(optional: turbo pump, poly cold system) Air system: Mass flow controller (1-4road) Ultimate vacuum: 6x10-4pa (no-loading, clean chamber) Pumping time: No-loading from air to 5x10-3pa<13mins Workplace motion mode: 6 axis/8axis/9axis public and self-rotation

Request for a quote

APT ANGEWANDTE PROZESSORTECHNIK GMBH

Germany

Overpressure and vacuum possible - Different pressure and flow ranges possible - Several measuring ranges possible in one device - Modern operation via 5" touch graphic colour display - Completely remote controllable, optionally via ProfiNet

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix gas dosing stations for physical foaming have been specially designed and developed to meet the needs of foam extrusion. Promix gas metering technology is characterized by high dosing accuracy, reliability and amazingly simple operation. Promix gas dosing stations meet all the requirements of a modern gas metering system for foam extrusion. These include high-precision mass flow control, process visualization by means of trend charts, operator-definable operating limits, data acquisition, and synchronization of the dosing rate with the extruder output. Implementation in the extruder control system via fieldbus system is also possible. •,Mass flow from 1 g/h up to 20'000 g/h •,Dosing pressure up to 680 bar

Request for a quote

AHP PLASTIK MAKINA

Turkey

DSC for determining the oxidation induction time for polymer pipe and protective pipe systems as well as moulded elements made of polyolefin. Suitable for OIT test and Melting point determination According to ASTM D3895 ISO11357 EN728 ASTM D3418 up to 500C Including standard Tin, Ind pellets for calibration checkout, 400pcs of aluminium pans, Software CD (windows based software including Report out to WORD), N2 and O2 rotameter mass flow controller, Hoses and connectors, Software also has data export to advantage Software for analysis, DSC measuring cell according to the heat flux principle, temperature sensors for control & sample temperature, Connection for Purge gas flow to the sample for 2 gas types, Temperature accuracy 0.1 C, Sensitivity: 3.6 to 4.0 μV/mW , Sensor Time constant: 2.5 s, calorimeter accuracy of ± 2% and calorimetric precision of ± 0.5% or better, Two connections for purge gas-Inlet to the sample & 1 connection for protective gas Inlet with gas flow adjustment,

Request for a quote

BÜCHI AG

Switzerland

We offer various solutions for liquid dosing. Based on parameters such as flow rate, dosing accuracy, properties of the media process and regulatory requirements we select the appropriate method of dosing as well the most suitable dosing instruments. Dosing methods used, include gravimetric dosing with load cells, various types of dosing pumps and dosing with pumps using mass flow controller (MFC) and level sensors.

Request for a quote

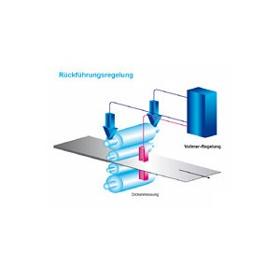

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The high-speed servo-hydraulic control of the mill screwdown closes the loop: The thickness values measured precise to the micrometre form the basis for quick and precise control. Vollmer offers solutions for all control concepts from simple feedback control through to complete mass flow control or Direct gap contol for rolling of wedge-shaped strip and in tandem mills. Vollmer supplies the complete control system – from the sensors through the control technology right up to the hydraulics and the cylinder – from a single source. For our customers that means having just one contact partner – in short: A one-stop solution.

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

for small pipe size DN8~DN50 micro mass flow designed to measure the mass and standard flow in small pipe lines in general industry and laboratory

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

TGF600 Screw-in thermal mass flowmeters for small pipe size gas meausred Inline type can be installed/removed without stopping the line Minimum flow rate down to 0.3m/s, 1:100 super wide turndown ratio No moving part, almost no pressure loss Direct mass flow measurement, do not require temperature or pressure compensation TGF600 Series screw-in inline thermal mass flowmeters measures the gas mass flow base on thermal dispersion theory. It combines COMATE’s advanced technology on transmitter, sensor, filming and calibration, can provide stable and accurate measurement even under harsh industrial applications and require very less maintaining.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you standardised complete systems for the measurement of volume & mass flows. The EP LMF®-LaminarMasterFlow® is a complete system for high-precision flow measurement of gases and air. The LMF® system consists of a flow processor, a Laminar Flow Element (LFE) as measuring section, a cable set and a sensor package. The flow measurement is performed by means of Laminar Flow Elements (LFE), which are available in different sizes and cover a measuring range from 0.01 to 700 m³/h. (optionally up to 4000 m³/h).

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

COMATE Inline thermal gas flowmeters with more rugged design to adapt to harsh industrial applications. It implements COMATE’s latest sensor filming technology and high sensitivity sensors to ensure a stable measurement at very low flow rate down to 0.3Nm/s. The standard insertion model can fit in pipe line from DN80~DN500, extended model can fit in smaller pipe down to DN25 and larger pipe up to DN 6000.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Flow-Trigger™ is an industrial flow switch designed and calibrated to confirm minimum or maximum flow rate within a pipeline. The Flow-Trigger™ combines a fully calibrated flow orifice and an explosion proof differential pressure switch to reliably monitor gas flow within the most demanding hazardous industrial environments. The Flow-Trigger™ is designed to be suitable for use with most industrial gases including hydrocarbons and corrosives like ammonia. Every Flow-Trigger™ comes complete with an orifice calibration curve and is preset to trigger at the desired set point based on the provided inlet gas specifications. The switch is field adjustable (+/- 40% of initial flow set point) after installation so that it can be fine tuned to meet specific application requirements. The Flow-Trigger™ is designed to be easily installed directly into a gas pipeline and comes complete with the required inlet and outlet pipe to maintain calibration accuracy.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The SAV Plus™ is a heavy-duty position control valve that maintains a valve's position based on a desired % output set point. It is designed to work in applications where the control of a process variable (PV) is accomplished using an independent sensor. Perfect for controlling Dew-point, Carbon Potential, etc. The SAV Plus™ incorporates a standard Waukee Flo-Meter scaled to the application requirements and an electronic control valve that modulates flow based on an external signal from a control system. The external signal can be 4-20mA or may be delivered using digital communications. FEATURES • Large LCD display provides vital information such as Valve position, Alarms, and diagnostic messages • Simple and intuitive programming menus • Field programmable engineering units • Standard Modbus TCP for easy integration with control systems • Manual actuation of valve possible • Built-in Web Server for remote access to device • Calibration in state-of-art ISO/IEC 17025:2005...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Valve-Tronic Plus™ is designed for use in highly demanding industrial applications that require accurate flow control and measurement. It can function as a stand-alone controller for basic applications or become an integral part of a process control system for automatic flow control. FEATURES • Large LCD displays actual flow rate, totalized flow, valve position, alarms, and diagnostic messages • Field programmable engineering units • Magnetic sensor technology immune to problems related with dirty oil • Configurable to control based on rate of flow or valve position for applications where the Process Variable (PV) is Dew-point, Carbon Potential, etc. • Standard Modbus TCP for easy integration with control systems • Manual actuation of value possible • Field calibration for null and span • Advanced polynomial calibration for high accuracy over the entire range of the meter • Built-in Web Server with remote access to device • Full PID setpoint control The VALVE-TRONIC Plus™...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Liquid FurnaceMeter™ is available for liquid flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the liquid type, inlet pressures, and scale ranges to provide precision process control for most applications. The Liquid FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The Liquid FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The Liquid...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for gas flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™ meets current NFPA86...

Request for a quote

VENRIUS B.V.

Netherlands

Venrius' portfolio includes a variety of variable area flowmeters. Metal tube variable area flowmeters, glass tube variable area flowmeters, and purge rotameters are the three main types. The volumetric flow rate of liquids and gases is measured using the float principle in metal and glass tube flowmeters. The purge flowmeter is intended for general use as a low-cost method of flow indication. It is suitable for the majority of non-critical purge applications that do not necessarily require high flow measurement accuracy.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mass flow controllers - Import exportNumber of results

17 Products