- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire rope cutter

Results for

Wire rope cutter - Import export

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For cutting wire ropes and steel wire without any burr or splaying • For wire ropes 1570 N/mm² • Cutting edges inductively hardened • With optimum leverage for easy and effortless work • Handles made of precision steel tube • Insulation according to DIN EN/IEC 60900

Request for a quote

KW HYDRAULIK GMBH

Germany

Cable Cutters Wire Rope Cutters Rebar Cutters Steel Cutters Chain Cutters Chain Blasters Cutter for Wire of Prestressed Concrete Flat Bar Cutters Thread Cutters Nut Splitters Nibblers for Sheet Metal Cable Stripping Tools Sheat Peeling Tools

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

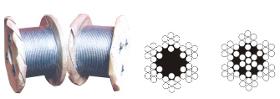

round wires for crane ropes, lift ropes, lifting systems, mining ropes, forestry applications, architectural ropes, ropes for automotive and aviation, special ropes for offshore technology, profile wires for special applications, fully locked / semi-locked ropes for tensioning systems, mountain railways, transport systems, profile wires for reinforcements in the offshore sector.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable to form a cable ring.

Request for a quoteResults for

Wire rope cutter - Import exportNumber of results

7 ProductsCountries

Company type