- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire bending

Results for

Wire bending - Import export

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Finger bender technology on our X2000NC This is new and revolutionary! Do you know our X2000NC? Then you know the advantages of our variable, modular machine concept. In this new model, we have consistently transferred the finger bending technology of the SPEEDMAX to the X2000NC. This model now combines all the advantages of two bending worlds. By integrating the NC bending technology in combination with our rotary positioning pliers and the servo transfer, the X2000NC is now pushing material speeds to a whole new level. E.g.: Up to 40 parts per minute, each one with up to 6 bendings and 1 press operation is possible

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We are specialized manufacturers of wire products tailored to the requirements of our customers. We operate two modern CNC 3D wire bending centers with the following parameters: CNC bending wire center Numalliance 310 OPT Machine parameters: Max. wire tensile strength: up to 600 N/mm² or 85 Ksi Wire diameter: From 2.5 to 10 mm 3D CNC bending wire center Numalliance 214 TF Machine parameters: Max. wire tensile strength: up to 600 N/mm² or 85 Ksi Wire diameter: From 2.5 to 14 mm These machines enable us to create complex and precise shapes according to specifications, ensuring high quality and customer satisfaction.

Request for a quote

JSC SAKCABLE (SAKCABLE)

Georgia

The aluminum cores with section 2,5-50mm2 inclusive are made of single wire with 1st class flexibility, 70-240mm2 inclusive with twisted multi-core wires with 2 class flexibility, according to Gost standard 22483-77. Number of cores in the cable 1,2,3,4,5The insulated cores are made of different colors, an inscription is made on the cover of the conductor “JSC Sakcable” cable brand, year of production. Labelling of cores with colors or figures 0,1,2,3,4.

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

GENERAL OPERATION The machine is built-up of a rotating plate and a knot device that allow to create the requested wire ties. When the cycle is running, the pinch roll insert the wire in the machine and the rotating plate starts to rotate creating the wire ties. The crossed ends of the wire are held together and twisted by rotation of the gripper. AUTOMATIC CYCLE When the operator press the “start” button, the automatic cycle command is sent to the machine. This signal allow to insert the wire into the rotating plate following the sequence below: - Realignment and lifting of the twister. - Realignment of the wire step cylinder. - Closing of the pinch roll. - Moving forward of the puller. - Insertion of the wire by means of forward rotation of the pinch roll. When the twister is in high position, the puller is moved forward, in order to pull out the wire ties. With a time delay, the machine starts a new tying cycle (according to the number of the ties set in the operator’s panel).

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

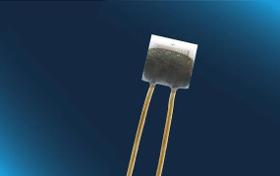

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product model :X-7600 Magnification :200X Detection accuracy :5um The use of the world's top HAMAMATSU Japan X-ray source can easily identify the semiconductor packaging gold wire bending gold wire fracture, large load table, can be placed in a large industrial control board ultra-long LED light bar applicable to various fields of electronic products

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

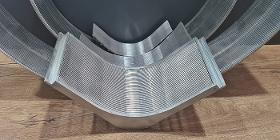

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

DIETZ GMBH

Germany

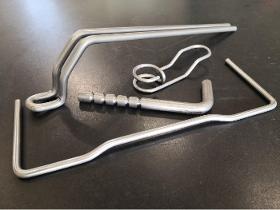

Bent wire parts represent a separate part of our production range. Bent parts differ from springs such as extension springs, compression springs and wave springs in terms of how they are produced. This type of spring is not only processed with automated machinery, but also involves a considerable amount of special handling, which we perform using our range of state-of-the-art equipment. Precision production with our high-tech machinery: Our range of machinery with an in-house toolmaking workshop enables three-dimensional bent parts to be produced with a wide variety of forms and with specialised finishes applied to the ends. Our range of machining processes includes: Bevelling, embossing, thread cutting, thread rolling, turning and milling. For bent wire parts, both CNC bending and mould-based bending are possible as production solutions.We process wire thicknesses of 0.20 to 8.00mm.Tool-based: 0.50 to 8.00 mm. Coating of part surfaces: Oiling, Vibratory finishing, Galvanisation.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg outsourcing steel wire forms by carbon steel wire, stainless steel wire, spring steel wire, we can custom fabricate almost any wire form using our automated wire bending robots. Beyond getting the shape you need, you can also order custom wire forms in a various of materials, such as stainless or galvanized steel, with a variety of coating options, including soft polymers and scratch-resistant hard polymers. We custom producing all kinds of steel wire forms, includes steel wire brackets,steel wire hooks, steel wire baskets, spring bracket, steel wire cover, steel wire lampshade for lighting, steel wire clip, spring steel wire formed shield, wire forms, steel wire hooks, steel wire suspend slings, and all steel wire parts. Our steel wire forming products mainly use in Animal stock breeding, Garden & constructions, Automobile,Machinery…

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with 2 bending heads for the production of stirrups and shaped wires with bends at both ends using wires up to Ø 16 mm (#5). Driven by electric servomotors. Also available HS version machine. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 140 m/min (460 ft/min) HS Version 200 m/min (660 ft/min) Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick AntiTwist electronic device (Optional) Patented feed unit that allows independent advancement for single o double wire (Optional) 2 bending unit (upper and lower) 4 pulling drive wheels Cutting unit with adjustable wire guide, reversible mobile and fixed cutting blades Web Teleassistance 3D version for the production of tridimensional pieces.

Request for a quote

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with disk bending system for the production of stirrups and shaped wires with bends at both ends using wires up to Ø 16 mm (#5). Driven by electric servomotors. This automatic shaping and stirrup bender from coil is equipped with Max. pulling speed 140 m/min (460 ft/min) HS Version 200 m/min (660 ft/min); Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick; Disk bending unit; Cutting with Brushless motors; Cutting unit with adjustable wire guide, reversible mobile and fixed cutting blades; Web Teleassistance. The 'bridge' version (Opera 16 Bridge) is suitable for accepting an optional mobile carriage which allows collecting and classifying the manufactured stirrups and rebars.

Request for a quote

SCHNELL SPA

Italy

Bidirectional stirrup bender and bar shaping machine from bar for the production of stirrups, shaped wires and cuttosize bars using bars up to Ø 25 mm (#8). Driven by electric servomotors. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 120 m/min (400 ft/min) Semiautomatic cycle for shaped wires with bends on both ends Virtual mandrel Web Teleassistance Automatic loader Genius (Optional) 3D version for the production of tridimensional pieces.

Request for a quote

SCHNELL SPA

Italy

Bidirectional automatic stirrup bender for the production of stirrups and shaped wires both from bars (up to Ø 22 mm #7) and from coils (up to Ø 16 mm #5). The lower bending unit performs downward bends. Driven by electric servomotors. These automatic stirrup benders are equipped with Max. pulling speed 100 m/min (330 ft/min) External and internal straightening unit Semiautomatic cycle for shaped wires with bends on both ends Barholding clamp for downward bends Virtual mandrel for the upper processing unit Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Bidirectional stirrup bender and bar shaping machine from bar for the production of stirrups, shaped wires and cuttosize bars using bars up to Ø 22 mm (#7). Driven by electric servomotors. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 120 m/min (400 ft/min) Semiautomatic cycle for shaped wires with bends on both ends Virtual mandrel Web Teleassistance Automatic loader Genius (Optional) 3D version for the production of tridimensional pieces.

Request for a quote

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with 2 bending heads for the production of stirrups and shaped wires with bends at both ends using wires up to Ø 20 mm (#6). Driven by electric servomotors. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 140 m/min (460 ft/min) Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick AntiTwist electronic device (Optional) Patented feed unit that allows independent advancement for single o double wire (Optional) 2 bending unit (upper and lower) Pulling with 4 motors and 4 pulling drive wheels Cutting unit with adjustable wire guide, reversible mobile and fixed cutting blades Web Teleassistance Prestraightening Feeding Unit (Optional) Automatic motorized wire change (Optional) 3D version for the production of tridimensional pieces.

Request for a quote

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with disk bending system for the production of stirrups and shaped wires with bends at both ends using wires up to Ø 14 mm (#4). Driven by electric servomotors. This automatic shaping and stirrup bender from coil is equipped with Max. pulling speed 150 m/min (500 ft/min) Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick Disk bending unit Cutting with Brushless motors Cutting unit with adjustable wire guide, reversible mobile and fixed cutting blades Web Teleassistance

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For cutting hard and soft wires • For holding, gripping, bending and cutting work • Cutting edges inductively hardened • With cutting edge and burner hole • With long, 45°-angled, flat-round jaws • Serrated inside jaws • Integrated ring spanner • Handles with ergonomically shaped SoftGripp multi-component sleeves • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For cutting hard and soft wires • For holding, gripping, bending and cutting work • Cutting edges inductively hardened • With cutting edge and burner hole • With long, 45°-angled, flat-round jaws • Serrated inside jaws • Integrated ring spanner • Handles with ergonomically shaped SoftGripp multi-component safety sleeves according to DIN EN/IEC 60900 • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Made of tool steel, forged, oil-hardened

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Our Capability Plastic & Metal part Machining Machining Type: Milling,Turning,Grinding,Tapping,Slotting,Knurling,Bending,Electrical Discharge Machining Wire cutting Machining; Part material machined:Aluminium,Brass,Copper,Bronze,Steel,Plastic( PP,PA6,ABS,PMMA,PC,PVC,POM,Bakelite etc.) Magnesium and Titanum; Main E-quipment:CNC Milling machine,CNC Lathe,automatical Lathe,Grinder,Electrical discharging machine,Wire cutting machine,bending machine; Part surface treatment :Polishing ,Sandblast,Anodization,blacking,Powder coating,Nickle,chrome ,zinc plate ,passivation etc. Quanlity Control: Key dimension 100% inspection before shippment; At least 4 times of inspection during production. Shipping Package:MFD Wooden box free of fumigation( big weight ); Carton (small weight). As per client's demand

Request for a quoteResults for

Wire bending - Import exportNumber of results

33 ProductsCompany type

Category

- Industrial cutting machine tools (8)

- Sensors (6)

- Bending machine tools (3)

- Forming - steels and metals (3)

- Bending - steels and metals (2)

- Building hand tools, non-power (2)

- Milling - steels and metals (2)

- Binding - machinery and equipment (1)

- Copper wires and cables (1)

- Filtering equipment and supplies (1)

- Finished Metal Products (1)

- Galvanization - steels and metals (1)

- Machine tools, metal machining - parts and accessories (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Moulds, precision (1)

- SMALL METAL PARTS (1)

- Semiconductors (1)

- Tying machines (1)

- Water treatment, industrial - systems and equipment (1)

- Wire springs (1)