- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded joints

Results for

Welded joints - Import export

QUELLTECH GMBH

Germany

Rotationally symmetrical driving gears in a line producing for automotive industry are mutually connected by electron beam welding. The camera inspection carried out until was not able to assess the quality of the weld seams at the required precision. Non-contact laser measurement system Particular Challenge: As the welding seams show a high reflectivity and are located at a position hard to access, inspection is difficult, all the more so as they dispose of a width of only 500µm. Therefore it is quite a challenge for the laser measurement system. The QuellTech solution: A QuellTech Laser Scanner Q4-5 with extremely small shape factor and high resolution proved to be perfectly suited for this application. In order to suppress reflections from elements in the surroundings, a particular algorithm has been integrated. Furthermore, this laser measurement system features a particularly adapted laser wavelength and an ultrafine laser line.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

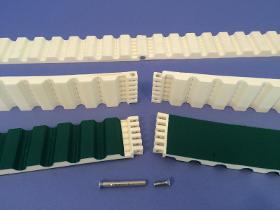

PU timing belts with easy joint as strong as a welded joint The easy joint timing belt fastener is the perfect solution, for a quick and easy mechanical endless connection of PU timing belts. Assemble without disassembling, without stopping your production line Replace your belts in few minutes without disassemble your hoods, pulleys, axis. Reduce your production downtimes. The method of mechanical assembly and fastening system easy joint offers unique solutions for easy and fast repairs of power transmission belts or conveyor belts. Pitches: H / T10 / AT10 / T20 / AT20 / 8M / 14M Standard: Polyurethane 90° Shore A grey Versions: Standard, PAZ, PAR Cords: reinforced with a Polymercord around the Pin in each tooth joint, arranged in parallel Width: from 10 to 150mm, (wide belts possible on request)

Request for a quote

NOVELTY STEEL

Turkey

Welding Neck (WN) Flange Slip-On (SO) Flanges Socket Weld (SW) Flanges Lap Joint (LJ) or Van Stone Flanges Threaded or Screwed Flanges Blind Flanges Custom Flanges and fittings

Request for a quote

ANTHERMO GMBH

Germany

Combination of welding outlet and flange Nipoflange in pipeline construction A nipoflange is used in pipeline construction just like a welding outlet or a nipple outlet for a 90 ° branch. A Nipoflange is a combination of welding outlet, nipple outlet and flange. Further terms for Nipoflange are Weldoflange or Flangeolet. Two different branch sides On the pipe branch side , a nipo length has the shape of a welding outlet. This means that the branch from the pipe is made with a welded joint. There is a flange on the connection side, ie a flange connection is created. The flange can be designed according to customer requirements (usually according to DIN or ANSI). Nipoflange as a forged fitting A nipoflange (similar to ANSI B 16.9 / MSS-SP 97) is usually made from a forged blank. This means that a Nipoflange is a forged fitting and has no welds.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain has been developed for applications where the requirements for precision are not the primary focus, but rather where an economical purchase price and simple functionality are the key criteria. The sensor‘s strain gauge technology allows both static and dynamically changing forces to be measured. The large display means that the force acting on the sensor can be read easily. The four integrated threaded holes allow the sensor to be integrated quickly and easily into existing production and assembly equipment. Typical applications include: —Testing the strength of welded joints —Sports medicine —Monitoring the clamping force of hose connections The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Plastic for welding … Welding is often the simplest and best way of fastening. The range of different perforated plates offers a wide range of applications. Size and quantity of the welding joints depend on the substructure and must be defined on site. Please note that the perforated metal sheet can under no circumstances take over any static functions. The secutex buffer pad is simply disconnected by grinding away the welding spots. These are the advantages Simply weld onto the item to be welded No need for repeatable holes in the workpiece No holes in the secutex impact protection material Applications On all metal surfaces On thin metal walls Everywhere where screwing is not possible or screw holes are unwanted Examples Collecting basins Ramp protection metal boxes Container Forklift Gripper Girder protection Pallet truck 1. Perforated metal sheet, overhang at the side This version is suitable for welding onto flat surfaces and extrawide profiles of construction steel.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

The requirements placed on components in the medical sector are extremely stringent, since, for example, the welds, in addition to the technical quality, must also meet the highest demands in terms of optics. For example, we produce stainless steel slideways for the slip rings of computer tomographs. We were also able to support our customers here in choosing the materials and the definition of the welded joint.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

MAPP Gas & Hard Torch SetThis series of portable welding gun is suitable for red welding joints Between various non-ferrous metals, and for melting welding between similar non-ferrous metals with low melting point (such as aluminum + aluminum, brass + brass jcintsi; for rod welding between ferrous metals, and welding joints composed of ferrous metals and non-ferrous metals, selecting appropriate rod materials and flux can also obtain good rod welding joints. Commodity characteristics: 1. Safe, convenient, professional and concise. 2.The combustion temperature of.HT MAPP GAS can reach above 1250 C without oxygen and combustion. 3.HT MAPP CAS is a patent formula gas for mixed gas. 4. Diameter 75mm. high 267mm for single hand welding, easy to carry. S.Scientific mixing ratio, good flame characteristics, so as to ensure the welding effect and shorten the working time. 6. Under normal working conditions, it can achieve continuous combustion time of 2 hours and 30 minutes.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Protection of welded joints. Allows welded parts to be lacquered. GALVASPRAY sprays a protective zinc finish. High resistance to oxidation and corrosion (more than 80 hours in salt fog) Quick drying (about 5 minutes) and no drips. Volume: 400 ml (liquid) - 520 ml (nominal). Propellant gas: propane/butane. Base: zinc powder in vegetable resin. Instructions for use: Clean and degrease the area to be treated. Shake the can before using for at least 1 minute. Spray 25 cm away from the piece in short, even passes.

Request for a quote

ERO JOINT .TANALS

France

In all cases, the mechanical fastening systems ERO Joint® are linked to a traction cord embedded in the belt in order to provide the required mechanical resistance. (ERO Joint® is also available in belts without traction cord). In such cases, a traction element is added to assure the mechanical resistance of the mechanical hinge joint. Anyway using ERO Joint® V-belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® trapezoidal belts are easy to assemble.

Request for a quote

ERO JOINT .TANALS

France

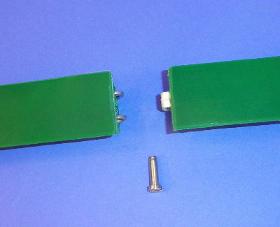

The mechanical fastening system ERO Joint® is available in flat belts with a thickness over 1mm containing an intermediate layer of Polyurethane. The assembly is made by threading of 3 transversal pins. Anyway using ERO Joint® flat belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® flat belts are easy to assemble. Advantages are a fast and easy installation and assembly. With this new lacing technology, you will save time and optimize your production downtime by reducing the repair time.

Request for a quote

ERO JOINT .TANALS

France

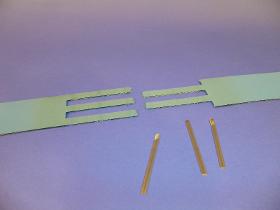

The mechanical fastening system ERO Joint® is available in conveyor belts with a thickness over 1mm. The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins can be used). ERO Joint® splice is integrated into the conveyor belt, with no structural, width and colour changes. Tensile Kevlar cord can be embedded in Polyurethane upon request. Anyway using ERO Joint® conveyor belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® conveyor belts are easy to assemble.

Request for a quote

ERO JOINT .TANALS

France

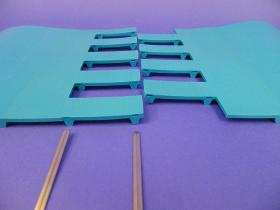

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical joint system, you will save time and optimize your production downtime by reducing the repair time. The mechanical assembly of ERO Joint® round belts is substantially better compared to another mechanical joint system. There is no other mechanical joint system in round belts with traction cord. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® round belts are spliced in our production using a patented process and fitted with the length requested. Anyway using ERO Joint® round belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® round belts are easy to assemble. Alternatives Hollow round belt with fastening system Hollow round belt with connector are only used for very low mechanical resistance.

Request for a quote

ORBITEC GMBH

Germany

A precise 90° saw cut is a basic requirement for orbital weld preparation. Robust saws for all wall thicknesses Powerful drive motor Uniform and easy feed control by means of handwheel Different chamfering blades mountable Right-angled saw cut 4, 5 or 6 clamping jaws made of stainless steel as well as reducing jaws Due to concentric clamping no deformation with thin-walled pipes Also for cutting off pipe bends Quick-release fastener for easy changing of saw blades Chip removal during cutting by means of integrated brush Convenient adjustment of plunge depth by means of feed wheel Technical Data: Size range in mm: OD 6 – 220mm Size range in inch: 0.236″ – 8.661″ Wall thickness: 1 – 8mm Electric drive: Single-phase AC motor Mains voltage (input): 200/220VAC (50/60Hz) Power: 1000W / 4.5A Protection class: II Speed control: 6-step control Weight: 47 - 77kg Package includes: Tube saw with electric drive One saw blade One bottle of saw blade lubricating oil

Request for a quote

ORBITEC GMBH

Germany

Open weld heads are clamped on one side of the weld joint. During welding, the gas- or water-cooled torch with hose package rotates around the tube. Advantages of open weld heads: — Robust design — Extremely easy to use — Option of using additional wire — Stepless tube size range — Torch bracket has 90° tilting function Weld head \ Tube size range mm \ inch \ weight \ item number OSW 40 \ OD 8 - 40mm \ 0.394" - 1.575" \ 2kg \ 1.3.1001 OSW 80 \ OD 10 - 76.2mm \ 0.394" - 3.000" \ 3kg \ 1.3.1101 OSW 115 \ OD 20 - 114.3mm \ 0.787" - 4.500" \ 4.5kg \ 1.3.1201 OSW 170 \ OD 40 - 168.3mm \ 1.575" - 6.626" \ 6.5kg \ 1.3.1301 OSW 275 \ OD 88.9 - 273mm \ 3.500" - 10.748" \ 16kg \ 1.3.1401 \ rotor can be decoupled Package includes: — Weld head — Integrated start/stop button on the handle — Top jaw — OSW torch bracket (with roll scanning in the case of OSW 275) — Mechanical headway control Optional: Angular gearbox for OSW on request

Request for a quote

ORBITEC GMBH

Germany

The 5th generation of our reliable, tried-and-tested standard controller. Can be connected to Tetrix 200 or Tetrix 351. — 5.7" display — Extremely simple multilingual user guidance thanks to programming support — Monitoring of gas and water cooling — Option of welding in up to SIX sectors, in continuous or step travel mode — Individual modification of the calculated program parameters, also using current percentage button — Graphic display of the welding progress — Real-time monitoring of the welding parameters — Integrated day counter (assignment to isometries and weld joint numbers) ... Package includes: — Controller — Power cable — Controller / power source interface cable — USB stick — 2 pieces tungsten boxes — Pen with touch screen function and LED light Optional: — Cool 50 or EVO Cool cooling unit — AVC upgrade kit — Docutronic 2.2 software for documentation — Orbicontrol 3 remote control — Spare paper rolls, spare ribbon cartridges

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® C 276 is a Nickel-Molybdenum-Chromium-Tungsten alloy with a high level of corrosion resistance. A low carbon content enables the alloy to resist intergranular corrosion at weld joints. These attributes make it an important alloy for the most severe chemical processing applications. such as use in metal diaphragms for aerospace sensors and burst discs. The alloy is readily formed from the annealed temper.All standard welding methods except oxy-acetylene can be used for joining. Available Sizes: HPM® C 276 is available from Hamilton Precision Metals as strip product in thicknesses From 0.0005” to 0.050” (0.0127 mm to 1.27 mm) and widths up to 12.0” (304.8 mm). The material conforms to ASTM B575 and UNS N10276.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

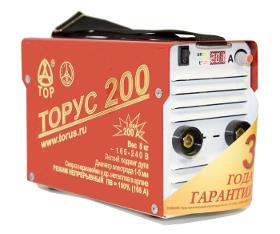

COMPANY TOR

Russia

ТОРУС-200 is a modern welding inverter device based on a digital high-frequency mains voltage transducer. The device is designed for electric arc welding of low-carbon, alloy and stainless steels, it can operate in TIG and MMA modes. Obtaining high-quality welding joints does not require high qualifications from the employee, which is important for novice welders. In short-circuit mode, the device almost does not consume current, which allows it to be powered from petrol power units with a capacity of 4 kW (6 kVA) and a household network with slumps up to 165 V. ТОРУС-200, like other inverter welding machines of the ТОРУС line, allows you to get welding with stable parameters. It is characterized by: small weight – 5 kg, high performance factor and the ability to work with electrodes with a thickness from 1.6 to 5 millimeters. In addition, the ТОРУС-200 welding inverter is designed for continuous operation not only indoors, but also outdoors.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Rodar® is an Iron-Nickel-Cobalt alloy with an unique linear thermal expansion coefficient. It is also stable to cryogenic temperatures. This combination of characteristics has prompted its application in electrical package sealing of glass/metal and ceramic/metal. Rodar® can be formed and deep drawn from the annealed temper. A 1/8 hard temper is optimum for heavy piercing.The material can be joined to other metals by welding, brazing, and soldering. The joint design must consider that Rodar® has a lower expansion coefficient than most other metals. Available Sizes: Rodar® is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.060” (0.0254 mm to 1.524 mm) and width up to 12.0” (304.8 mm). The material conforms to ASTM F15, AMS 7728 and UNS K94610.

Request for a quote

IRIDA LLC (UFANET GROUP)

Russia

It is applied in private houses during installation of PON networks. The cabinet has 4 slots for placement – removable panel for optical crosses or optical divider cassette type (130x100x25 mm). In addition, the cabinet can accommodate up to 3 ku-1 cassettes for optical fiber welded joints.

Request for a quote

FOXLASER

Bulgaria

The mechanical processing of the already cut parts – withering of edges after cutting, smoothing of welded seams and joints, polishing, grinding, are the necessary final steps in the processing of parts made of sheet materials. This type of treatment is recommended not only for visual and aesthetic purposes, but also to improve the quality of subsequent coatings. We have special, automatic and manual machines for mechanical processing, which meet the requirements of ISO 13715 for withering of all cutting edges. For small products we use trowalizing machines. The types of mechanical processing of metals allow different subsequent effects: polishing – mirror effect, satin finish (creasing) – brushed effect, matting – matte effect. In addition to the decorative purposes, we mechanically process many of the parts we produce after welding, in preparation for the application of subsequent coatings.

Request for a quote

UNECOL ADHESIVE IDEAS, S.L.

Spain

Cleaning solvent for use in welded joints in polyethelyene (PE), polypropylene (PP), polybutene (PB) and Polyvinylidene fluoride (PVDF) pipes.

Request for a quote

VILLINA LLC

Russia

During the construction of an industrial facility, much attention is paid to the strength of the service pipelines fasteners. It is also necessary to provide reliable connection of all units of industrial equipment with the pipelines. In this case, it is not always possible The use of a permanent welded joint is not always possible, therefore, there are various types of weld-free tight joints. FLANGE JOINT COMPONENTS At present, one of the most effective connections used in industrial facilities is a flange joint. This is an airtight connection that provides high structural integrity, consists of two flanges, fasteners (studs or bolts, washers, nuts) and gaskets. An important matter in choosing a set of flanges is tightness. The gasket material must have good elasticity, strength, resistance to the operating temperature conditions and to the media with which direct contact is expected. For flange joints, Villina company uses the following types

Request for a quote

INTER ATLETIKA

Ukraine

This line of machines provides a great functionality, unique design and exceptional ergonomics. X-line R made in a high-tech style - strict angles and sharp edges, which give futuristic and presentable appearance to the equipment. Also the series is distinguished by smart design of the constructions, reflected in perfect usability and total comfort of training. This would be the best choice for the gyms, where not only functionality but the aesthetic aspect is important. Metallic frame is performed using high-precision composite profile bending technology. Weld joints are done smooth and accurate. The frame is covered with electrostatic powder coating. You can order the frame constructions in black, white, grey, grey metallic and dark-gray colors. The seats of training machines are performed according to the anatomic properties of human body. Wide range of color combinations are available. Without a doubt this line is the best seller of Inter Atletika.

Request for a quote

2K WELDING TECHNOLOGY MACHINE MANUFACTURING

Turkey

The 2Kwelding CBS series of column & Boom Manipulators are specially designed and produced for harsh and rugged area circumstances. Column-Boom Systems are manufactured to ensure ergonomics during weld jointing processes, reaching to hard to access areas while welding large pieces and to perform welding with minimal error.. Column-Boom systems approach to the most suitable area on the piece for performing the required welding process under control of the operatör and welding operation is performed with the command sent to the automatic unit on the boom While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail.

Request for a quote

2K WELDING TECHNOLOGY MACHINE MANUFACTURING

Turkey

The 2Kwelding CBS series of column & Boom Manipulators are specially designed and produced for harsh and rugged area circumstances. Column-Boom Systems are manufactured to ensure ergonomics during weld jointing processes, reaching to hard to access areas while welding large pieces and to perform welding with minimal error.. Column-Boom systems approach to the most suitable area on the piece for performing the required welding process under control of the operatör and welding operation is performed with the command sent to the automatic unit on the boom While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail.

Request for a quote

2K WELDING TECHNOLOGY MACHINE MANUFACTURING

Turkey

The 2Kwelding CBS series of column & Boom Manipulators are specially designed and produced for harsh and rugged area circumstances. Column-Boom Systems are manufactured to ensure ergonomics during weld jointing processes, reaching to hard to access areas while welding large pieces and to perform welding with minimal error.. Column-Boom systems approach to the most suitable area on the piece for performing the required welding process under control of the operatör and welding operation is performed with the command sent to the automatic unit on the boom While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail.

Request for a quote

PRJSC DNEPROMETIZ

Ukraine

In order to ensure the reliability of mobile fences "Dneprometiz" was the first in Ukraine to apply the latest technology of pre-processing of galvanized wire OXSILAN. Now the corrosion resistance of 2D fence mesh is increased 5 times! Galvanized carbon steel wire, standardized resistance of welded joints, Oxsilan nano-coating and polymer paint coatings made the fences resistant to the external environment. Cooperating with Dneprometiz, you get a welded 2d mesh: - made of galvanized wire - with a durable and high-quality coating - environmentally friendly - with a service life of 10-15 years. Mobile fences D-FENS "MOBIL" Bar diameter: 3-3.5 mm; Section width 1 200-3 554 mm; Section height: 1200 - 2000 mm; Cell size: 100x300 mm.

Request for a quote

PRJSC DNEPROMETIZ

Ukraine

In order to ensure the reliability and durability of sectional fences, "Dneprometiz" was the first in Ukraine to use the latest technology for the preliminary processing of galvanized wire OXSILAN. Now the corrosion resistance of industrial protection fence is increased 5 times! Galvanized carbon steel wire, standardized resistance of welded joints, Oxsilan nano-coating and polymer paint coatings made the fences resistant to the external environment. Cooperating with Dneprometiz, you get a industrial protection fence: - made of galvanized wire; - with a durable and high-quality coating; - environmentally friendly; - with a service life of 10-15 years. Choice of 2 RAL colors: 1021 (rapeseed yellow), 1026 (luminescent yellow). Industrial in-shop fences (for equipment) "PROTECT" Bar diameter: horizontal: 2.8-4 mm; vertical: 2.8-4 mm. Section width: 1000, 1500 mm; Section height: 1500 - 2400 mm; Cell size: 25x100 mm, 50x50 mm

Request for a quoteResults for

Welded joints - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Conveyor belts (5)

- Abrasive discs (4)

- Autogenous welding machines (4)

- Welding, soldering and brazing - equipment and supplies (3)

- Flanges (2)

- Steel & Metals (2)

- Wire mesh (2)

- Laser - cutting and welding machines (1)

- Apparatus for gymnasiums (1)

- Cables & Networks (1)

- Expansion joints - ferrous metal (1)

- Expansion joints - non-ferrous metal (1)

- Harvesting machinery and equipment (1)

- LPG, industrial installations (1)

- Lightweight metal scaffolding (1)

- Power saws, portable (1)

- Professional fitness equipment (1)

- Pumps (1)

- Refrigerants (1)

- Road transport - tankers (1)