- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wave solder

Results for

Wave solder - Import export

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TITANIUM The new generation of wave soldering systems – lead free soldering without corrosion. TITANIUM is the innovative soldering solution developed by STRECKFUSS SYSTEMS. It uses titanium, an agent which is extremely lead free solder resistant. For this reason, titanium works perfectly in lead free soldering processes. An oxide film immediately covers all material damages and thus prevents corrosion. In contrast to wave soldering systems with stainless steel components, titanium is not subject to corrosion even when lead free solder is used. By means of a simple and safe solder bath exchange, TITANIUM makes it possible to switch flexibly from a standard soldering process to lead free production. This ensures maximum flexibility at minimum costs and easy handling. TITANIUM is a complete system and includes: Spray fluxer with extraction hood Double wave 3- D wave (for the prevention of solder bridges) Infrared preheating Microprocessor controls Soldering frame transportation system

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

SEACOMP

United States

Contract Manufacturing by SEACOMP Get your concept to physical product with our electronics manufacturing services. Use our engineering team to get your design ready for mass production or let us take your perfectly designed product and build it at scale. We help launch electronic devices for home automation, industrial controls, consumer products, and medical devices. Manufacturing is completed in our wholly-owned China facility that is ISO 13485 certified. Our production capabilities include: - PCB Assembly, Surface Mount (SMT), Through Hole Assembly - Wave Soldering - Reflow Soldering - Plastic Injection Molding (vertical and horizontal) - Ultrasonic Welding - Cable Assembly and Over-Molding We also provide the finished assembly of your product before it is shipped anywhere in the world: - Laser Marking - Pad Printing - UV Ink Curing - Label Printing - UV Light Metering - Box Build Assembly - Bulk or Retail Packaging - Warehousing Contact us to learn more.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

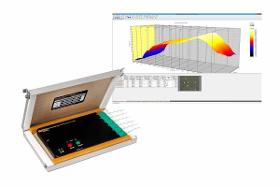

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework. For more details and specifications, download the Reflow Tracker System brochure. Insight Software for Reflow Tracker available in Basic, Standard and Professional versions Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AXON CABLE SAS

France

Connectors made by Axon’ Mechatronics are tailor-made. They are designed to be : -assembled to PCBA through different kinds of processes : wave soldering, reflow soldering or solderless solution. -assembled on Flat Flexible Cables or Flat Print Circuits with different processes : soldering, crimping, locking. -terminated to wire by welding or crimping. -assembled by electrical welding

Request for a quote

AXON CABLE SAS

France

As a specialist in interconnect and process automation, Axon' Mechatronics, a sister company of the axon’ group, offers interconnect solutions such as precision presswork, loose or reeled parts. Solutions Taped and loose parts Pressfit and PIHR (Pin In Hole Reflow) terminals for SMD PC board Complex conductor strips Lead frame SMD terminals and components Terminals for insertion and wave soldering (standard brochure) Advantages Simultaneous engineering : engineering of products and process Integrated tool workshop : Wire and spark erosion machines, grinding machine Stamping presses from 15 to 100 ton Manufacture of parts from 0.1 to 2 mm thickness Processing of all types of complex material Prototyping Applications Industry Consumer electronics Automotive

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Reflow Tracker temperature profiling systems Program includes — range of high-accuracy, industrial-strength, compact Datapaq DP5 data loggers — range of low-height thermal barriers — DATAPAQ Insight Reflow Tracker analysis software — selection of fast-response, high-temperature thermocouples for measuring SMD and PCB temperatures and process stability Applications include — WAVE SOLDERING – accessory: DATAPAQ wave pallet with up to 9 contact sensors and 3 preheat sensors; software functions include contact times and parallelism — SELECTIVE SOLDERING – accessory: DATAPAQ PA2200 selective soldering sensor for process stability measurement — VACUUM SOLDERING – optional data transmission via radio enables real-time data analysis — VAPOR PHASE SOLDERING – program includes a special range of sealed and lighter-weight thermal barriers — REWORK STATIONS – the DATAPAQ DP5 data logger with its USB and Bluetooth connectivity is ideal for high-speed, real-time monitoring

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

SELECTIO Selective soldering systems for automatic single point soldering and multiple point soldering It is not always possible to use mass soldering processes such as wave soldering to perform a certain soldering task. Individual soldering steps are often necessary. To automate this process and to lower the costs while maintaining the high quality requirements, STRECKFUSS SYSTEMS has developed the selective soldering system SELECTIO. Just like our wave soldering system TITANIUM, SELECTIO too is equipped with the corrosion and tin resistant agent titanium and therefore works perfectly for lead free soldering. Product characteristics – an overview: x/y/z- axes system with precision toothed drive belt transport system and assembly carrier standard stand- alone- system (offline system): optional transportation belt connection as inline system printed circuit board transportation with assembly carrier soldering processes: single point nozzle and surface nozzle as well as dip soldering via mask technique fluxing out of vendor's flux container with multi- drop- fluxer nozzle short wave IR- quartz- radiators for preheating of printed circuit boards pyrometer for contact- free temperature check of printed circuit boards easily exchangeable soldering nozzles Microsoft© Windows user surface and process visualization: - BDE for documentation complying with DIN ISO 9000 ff - management data organization - optional real- time video surveillance

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The triple AOI system is designed for simultaneous inspection at the return conveyor and from top and bottom before and after wave soldering oven. It has three multi-LED illuminated scanner units, as well as patented special optics which generate a parallax free image. The System includes three modus control units. The transport module has a length of 1200mm (47.2 in.). Characteristics: Triple system for simultaneous inspection of top and bottom before and after the soldering process. Optional automatic cleaning of the lower inspection area with an air knife. Combination of different inspection tasks such as SMD placement, THT solder joints, conformal coating and full screening for solder beads (solder balls). Capture of any number of barcodes and data-matrix codes on the multi PCB. Scan range 420 x 530 mm

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MCS42-SEL-AL is a cost effective camera-based AOI system. This solution is optimized for economical and flexible inline inspection of the several production processes. The small and inexpensive system comes with a 42 megapixel, high-definition industry camera and a PC equipped with the powerful modusAOI software whose development includes professional experience of two decades. Characteristics: Single system for inspection of objects. Combination of diverse application tasks in the THT area which take place before a wave soldering or selective soldering oven. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Whether with a mini-wave or a Wörthmann wave, we deliver customary RAFI Eltec quality on our automatic soldering equipment even for wired assemblies. We apply various technologies here – coordinated to each individual project. Our focuses: - Wired assembly - Wave soldering (ROHS-compliant or leaded) - Automated selective soldering - Lift-dip soldering (multi-wave) - Manual soldering - Assembly - Visual inspection You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quoteResults for

Wave solder - Import exportNumber of results

13 ProductsCompany type