- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water injection moulding

Results for

Water injection moulding - Import export

NORELEM FRANCE

France

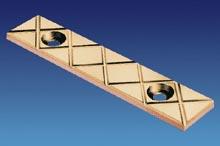

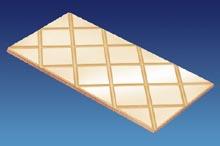

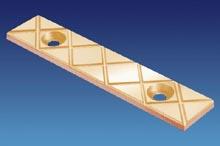

Injection moulded, straight teeth. Engagement angle 20°. Axis angle = 90°. Machined bores from module 1.5. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Machined bore. Polyacetal, white. Polyketone, ivorytone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. The torques specified in the tables relate exclusively to the toothing.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material: PP, ABS, POM etc. Surface treatment: machining surface Tolerence: 0.02 Machining method: plastic injection molding Usage: water purifier

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

NOVELTY STEEL

Turkey

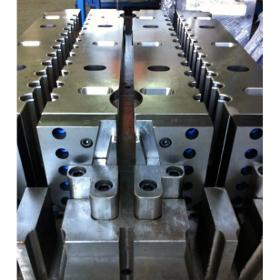

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions, ISO 9001:2015 & IATF 16949 accredited

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quote

HODA, UAB

Lithuania

HODA, UAB privately owned Lithuanian capital company, one of the biggest plastic injection moulders in Baltic states with 3400 m² area of production plant and 3500 m² of warehousing facilities. At the moment company operates 53 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts from a fraction of gram up to six kilograms of mass.

Request for a quote

HODA, UAB

Lithuania

At the moment HODA, UAB operates 54 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts.

Request for a quote

FATRA A.S.

Czech Rep.

Injection, injected products (from PP, LDPE, HDPE, etc. materials) – we offer the production on injection moulding machines with the clamp force of 420 – 800 t, moulded piece weight 80 – 3000 g. Our production assortment of injection-moulded products includes e.g. boxes, lids, tiles, protective plastic sides, or plastic containers. We offer the option of injection mould production including product development. Using your own moulds, any products according to specified parameters can be manufactured.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

Our injection department is also involved in injection molds testing. We test injection molds for tool shops and customers who import molds, e.g. from China. In addition to tool testing, we also assess the quality of workmanship, check the compliance of the construction documentation with the actual state and possible modifications to the forms.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

We design and manufacture injection molds. Our design department manufactures about 50-60 injection molds every year - only for its own needs. We design cold-runner, hot-runner, one-component and multi-component tools.

Request for a quoteResults for

Water injection moulding - Import exportNumber of results

34 ProductsCountries

Company type